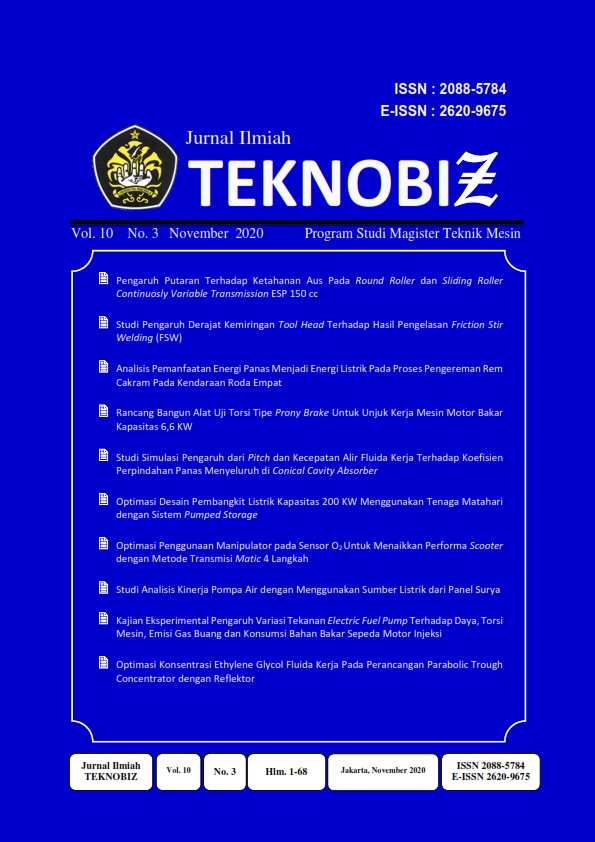

PENGARUH PUTARAN TERHADAP KETAHANAN AUS PADA ROUND ROLLER DAN SLIDING ROLLER CONTINUOUSLY VARIABLE TRANSMISSION ESP 150 CC

DOI:

https://doi.org/10.35814/teknobiz.v10i3.1756Keywords:

primary sheave weight (roller), tribometer pin on disk, wearAbstract

Primary Shave Weight or often called roller is one component of the Continuously Variable Transmission system on the ESP 150 CC automatic motor which is often damaged, both wear and crack or break. Wear and tear is a phenomenon of loss of material from its surface to another or the movement of material on a surface or surface displacement with the passage of time over time this wear will cause damage to the roller rubbing against each other. To understand the life of roller components, it needs to be studied further. In the field of tribiology studies of the phenomenon of friction, wear on two objects that are in contact. This affects the life of a component, especially those that move in fast conditions with the level of loading, the process of wear due to contact becomes three parts, which include material, environment, operating conditions and geometry of the surface of the wear object. To quickly determine the condition of wear, a tribometer pin on disk test equipment is needed, this tool is used to test round roller components and Continuously Variable Transmission sliding roller ESP 150 CC, where the material is PTFE. The design of the surface contact mechanism in the radial direction so that the disk can rotate and this test equipment is given a speed of 1000, 2000, 3000 Rpm with of loading of 3 kg. Tests are carried out experimentally to determine the occurrence of wear, from the initial conditions to continuous conditions. The results show that the tribometer pin on disk test equipment is feasible to use to determine the damage parameters that occur. By looking at the weight of the roller that is reduced due to friction