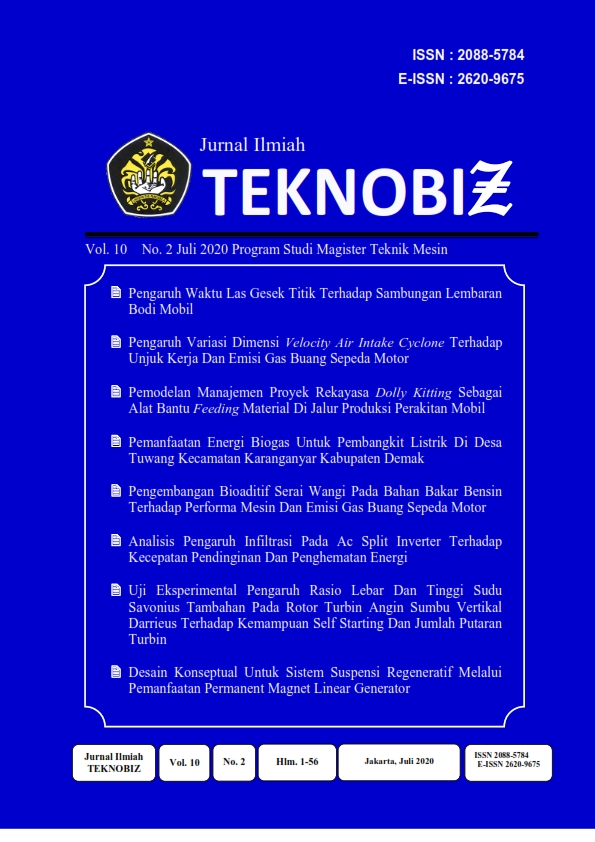

Pemodelan Manajemen Proyek Rekayasa Dolly Kitting Sebagai Alat Bantu Feeding Material di Jalur Produksi Perakitan Mobil

DOI:

https://doi.org/10.35814/teknobiz.v10i2.1458Keywords:

Dolly Kitting, Project Management, QCD.Abstract

The development of the Indonesian Automotive Industry in 2019 is expected to remain significant, this is shown from the sales of various brand vehicles in Indonesia which experienced an increase in 2018. To meet existing market demand, automotive companies need additional new investment in the form of various production equipment to anticipate schedules planned production. One type of production aids needed in car assembly lines is Rack, Tolley, Box (RTB) and Dolly Kitting. The demand for production aids is a real market opportunity, and this must be utilized by the local industry to take part in the development of the national automotive industry by supporting all of the automotive industries from all lines, one of which is in the process of providing RTB as a process aid production. PT ABC as one of the local producers of RTB providers, Dolly Kitting, seeks to seize this opportunity by implementing GMP. The methodology used is an engineering project management approach based on the principle of good manufacturing practices (GMP). From the model created, a product development engineering model can be prepared to deliver the product to the customer. Model conformity verification is carried out at various critical manufacturing points including product development, prototyping, production process preparation (3P) and ending with validation on the production floor through commercial prototypes before the product is released for commercial purposes as a method of maintaining product QCD.

Keywords: Dolly Kitting, Project Management, QCD.