Pengaruh Tebal Deposit Lasan Terhadap Properti Lapisan Menggunakan Elektroda HV 450

Effect Thickness on Layer Properties using HV 450 Electrodes

Abstract views: 220 | pdf downloads: 358

Abstract

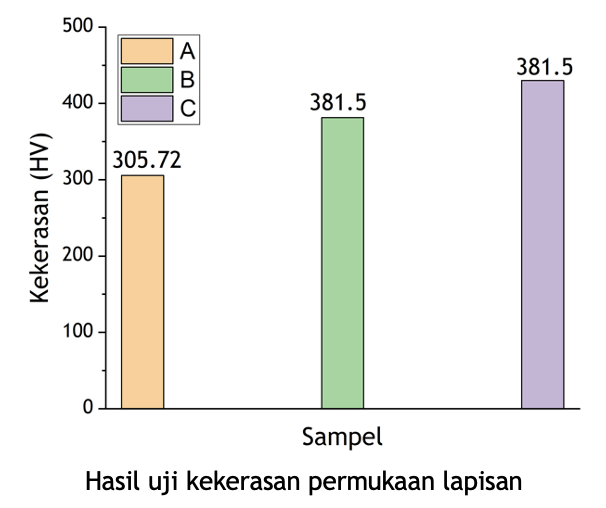

This study investigates the effect of the increased welding layers welded by the SMAW process on distorsion, thickness, microstructure, hardness, and corrosion. The method used in this research is experimental. Low-carbon steel with a size of 150x10x10 mm was welded by the SMAW technique using an HV 450 electrode. Variations in the welding layers are single, double, and triple. The three variations of the samples were observed with a digital camera and an optical microscope. Moreover, samples were tested with a hardness tester. Corrosion testing was also carried out to determine the corrosion rate of the layers formed. The results showed that the number of SMAW welding layers affected the thickness, phase, hardness, and corrosion rate. The hardness of one layer is less than that of thicker specimens, while the corrosion rate of three layers is lower than that of less-thick samples.

Downloads

References

Amat, M.A., Baskoro, A.S. dan Budi, D.R. (2023) ‘Pengaruh besaran arus dan kecepatan las terhadap angular distorsi pada SS304 dengan GMAW’, Journal of Applied Mechanical Engineering and Renewable Energy, 3(1), hal. 16–22.

Anggaretno, G., Rochani, I. dan Supomo, H. (2012) ‘Analisa Pengaruh Jenis Elektroda terhadap Laju Korosi pada Pengelasan Pipa API 5L Grade X65 dengan Media Korosi FeCl3’, Jurnal Teknik ITS, 1(1), hal. G123–G128.

Fontana, M.G. (1986) Corrosion Engineering. McGraw-Hill [Cetak].

Iswar, M. dan Syam, R. (2012) ‘Pengaruh Variasi Parameter Pengelasan (Putaran Dan Temperatur) Terhadap Kekuatan Sambungan Las Hasil Friction Welding Pada Baja Karbon Rendah’, Jurnal MEKANIKAL, 3(1), hal. 254–260.

Manalu, S.L.P. (2022) ‘Analisa Hasil Pengelasan Bawah Air Baja A36 Dengan Elektroda Air AWS E7018’, Jurnal Teknik Perkapalan, 10(3), hal. 31–40.

Nugroho, A. dan Setiawan, E. (2018) ‘Pengaruh Variasi Kuat Arus Pengelasan Terhadap Kekuatan Tarik dan Kekerasan Sambungan Las Plate Carbon Steel ASTM 36’, Jurnal Rekayasa Sistem Industri, 3(2), hal. 134–132.

Pazooki, A.M.A., Hermans, M.J.M. dan Richardson, I.M. (2017) ‘Control of welding distortion during gas metal arc welding of AH36 plates by stress engineering’, The International Journal of Advanced Manufacturing Technology, 88, hal. 1439–1457.

Pratiwi, Y.R. dan Wibowo, S.S. (2019) ‘Pengaruh Jenis Elektroda Dan Jumlah Pass Terhadap Uji Kekerasan Hasil Pengelasan Dan Struktur Mikro Pada Proses Pengelasan Shielded Metal Arch Welding’, Briliant: Jurnal Riset dan Konseptual, 4(2), hal. 159–166.

Rachmadi, M.A., Noerochiem, L. dan Nurdiansah, H. (2019) ‘Analisis Pengaruh Waktu Pencelupan Terhadap Ketebalan Kekerasan dan Ketahanan Korosi Hasil Elektroplating Nikel-Hard Krom’, Jurnal Teknik ITS, 7(2), hal. F257–F262.

Sitepu, N. dan Sukino, S. (2021) ‘Analisa Kekuatan Tarik Terhadap Jumlah Layer Pada Proses Pengelasan Kombinasi GTAW Dan SMAW Sambungan ST37 Posisi 3G’, Jurnal Teknologi Mesin UDA, 2(1), hal. 151–159.

Sopiyan, S., Susetyo, F.B. dan Syamsuir, S. (2018) ‘Pengaruh Arus Terhadap Kenyamanan Welder, Cacat Las Dan Kekerasan Hasil Hardfacing Baja Karbon’, Jurnal Kajian Teknik Mesin, 3(2), hal. 83–88.

Su, J. dkk. (2019) ‘Effect of Preheating Temperature on Microstructure and Properties of 42CrMo4/38MnVS6 Heterogeneous Laser Welded Joint’, Metals, 9(870), hal. 1–13.

Susetyo, F.B., Sutrisno, H.H. dan Suryadewi, R.A. (2021) ‘Studi Lapisan Hasil Hardfacing Dengan Variasi Arus Dan Elektroda AWS A5.13 EFe2/A5.1 E7018’, Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa Dan Inovasi, 3(2), hal. 97–104.

Swasono, T. dan Azriadi, E. (2018) ‘Pengaruh Arus Pengelasan Terhadap Kekerasan Hasil LasPelat Baja Karbon S45c Dengan Proses SMAW’, Jurnal Sains dan Ilmu Terapan, 1(2), hal. 19–25.

Turichin, G. dkk. (2018) ‘Influence of heat input and preheating on the cooling rate, microstructure and mechanical properties at the hybrid laser-arc welding of API 5L X80 steel’, in Procedia CIRP. 10th CIRP Conference on Photonic Technologies [LANE 2018], Germany: Elsevier, hal. 748–751.

Wardoyo, J.T. (2005) ‘Metode Peningkatan Tegangan Tarik dan Kekerasan pada Baja Karbon Rendah Melalui Baja Fasa Ganda’, Teknoin, 10(3), hal. 237–248.

Wibowo, H., Ilman, M.N. dan Iswanto, P.T. (2016) ‘Analisa Heat Input Pengelasan terhadap Distorsi, Struktur Mikro dan Kekuatan Mekanis Baja A36’, Jurnal Rekayasa Mesin, 7(1), hal. 5–12.