Efek Penambahan Penguat Serat Bambu Andong dan Serat Kaca pada Komposit untuk Aplikasi Badan Speed Boat

The Additional Effect of Bamboo Andong Fiber Enhancer and Glass Fiber on Composite for Speed Boat Body Applications

Abstract views: 233 | pdf downloads: 286

Abstract

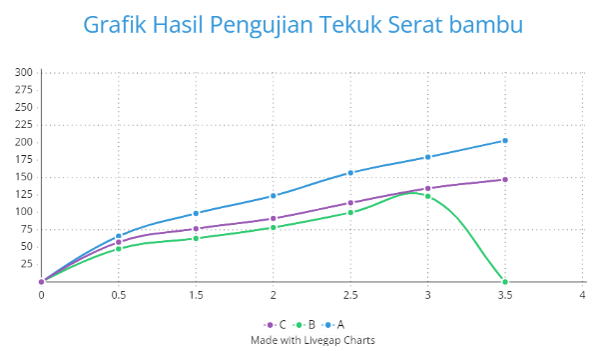

In materials technology, natural fibers can be employed as reinforcing materials to create materials that are lightweight, strong, environmentally friendly, and inexpensive. Bamboo is sturdy, light in weight, and simple to work with. The hull of a ship is the most critical component, and it needs to be made of material that is both strong and light. The hand-lay-up method is employed throughout the composite sheet invoice process. Reinforcing fiber content in composite material sheets varies by 4%, 5%, and 6% between the two types of fibers used: glass fiber and bamboo fiber. ISO 14125 Bending Test and ISO 527-4 Tensile Test According to the results of tensile testing on andong bamboo fiber, code A, which consists of 4% fiber and 96% matrix, has a significant strength value, and code C, which consists of 6% glass fiber and 94% matrix, has a significant strength value. According to the results of the bending test for bamboo fiber, code A, which consists of 4% fiber and 96% matrix, has a significant strength value. According to the results of research on the type of glass fiber, code C, which consists of 6% glass fiber and 94% matrix, has a significant strength value.

Downloads

References

Adriant, Z. dkk. (2019) ‘The Effect of Mesh Size on Mechanical and Thermal Properties of Bamboo Composites’, JEMMME (Journal of Energy, Mechanical, Material, and Manufacturing Engineering), 4(2), hal. 63–72.

Budiman, A. dan Sugiman, S. (2016) ‘Karakteristik Sifat Mekanik Komposit Serat Bambu Resin Polyester Tak Jenuh Dengan Filler Partikel Sekam’, Dinamika Teknik Mesin, 6(1), hal. 76–82.

Daroini, H., Nuriyah, L. dan Masruroh, M. (2014) ‘Studi Pengaruh Fraksi Volume Terhadap Ketangguhan Impak Komposit Polyester-Serat Kenaf (Hibiscus Cannabinus L.)’, Brawijaya Physics Student Journal, 2(1), hal. 1–3.

Eratodi, I.G.L.B. (2017) Buku Struktur dan Rekayasa Bambu. 1st edn. Indonesia: Universitas Pendidikan Nasional [Cetak].

Hadi, E.S., Jokosisworo, S. dan Widyanto, W. (2012) ‘Analisa Performa Hullform Pada Pra Perancangan Speed Boat Katamaran Untuk Search And Rescue (SAR) Di Pantai Gunungkidul Yogyakarta Berbasis CFD’, Kapal: Jurnal Ilmu Pengetahuan dan Teknologi Kelautan, 9(1), hal. 6–13.

Haryanto, E. (2018) ‘Pengaruh Modifikasi Buritan Speed Boat Terubuk Express 6 Terhadap Kecepatan Kapal’, INOVTEK POLBENG, 8(2), hal. 297–303.

Khalil, H.P.S.A. dkk. (2012) ‘Bamboo fibre reinforced biocomposites: A review’, Materials & Design, 42, hal. 353–368.

Ma’ruf, B. (2014) ‘Analisis Kekuatan Laminasi Lambung Kapal Fiberglass Yang Menggunakan Material Multiaxial’, Jurnal Standardisasi, 16(1), hal. 31–40.

Maryanti, B., Sonief, A.A. dan Wahyudi, S. (2011) ‘Pengaruh Alkalisasi Komposit Serat Kelapa-Poliester Terhadap Kekuatan Tarik’, Jurnal Rekayasa Mesin, 2(2), hal. 123–129.

Nugroho, W.T. (2015) ‘Pengaruh Model Serat Pada Bahan Fiberglass Terhadap Kekuatan, Ketangguhan, Dan Kekerasan Material’, Jurnal Ilmiah Inovasi, 15(1), hal. 27–32.

Primaningtyas, W.E. dkk. (2021) ‘Mekanisme Sintesis Komposit Berpenguat Serat Bambu Dengan Variasi Komposisi Sebagai Aplikasi Material Lambung Kapal’, Jurnal Teknologi Maritim, 4(1), hal. 1–4.

Setyanto, R.H. (2022) ‘Review: Teknik Manufaktur Komposit Hijau dan Aplikasinya’, Performa: Media Ilmiah Teknik Industri, 11(1), hal. 9–18.

Sulaiman, M. dan Rahmat, H. (2018) ‘Kajian Potensi Pengembangan Material Komposit Polimer Dengan Serat Alam Untuk Produk Otomotif’, in Prosiding Seminar Nasional Teknik Mesin (SISTEM). Seminar Nasional Teknik Mesin (SISTEM), Indonesia: Teknik Mesin Universitas Jember, hal. 1–7.

Sutardi, S.R. (2015) Informasi sifat dasar dan kemungkinan penggunaan 10 jenis bambu. 1st edn. Jakarta: Pusat Penelitian dan Pengembangan Hasil Hutan, Badan Penelitian, Pengembangan dan Inovasi, Kementerian Lingkungan Hidup dan Kehutanan [Cetak].