Taguchi Design of Experiment (DoE) for Evaluating TIG-welding Parameter Variations on Tensile-shear Load and Hardness Using Stainless Steel 304 Material

Abstract views: 250 | PDF downloads: 204

Abstract

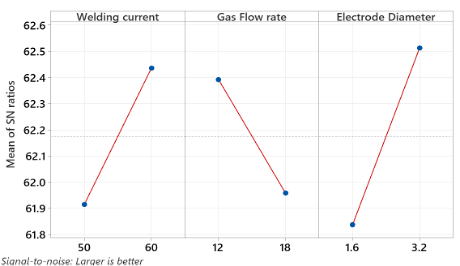

This article delves into the intricacies of optimizing the TIG welding process using stainless steel 304 (SUS 304) material, with particular emphasis on small-scale industries that are heavily reliant on TIG welding, especially in the production of household equipment and fences. The objective of this research is to enhance the tensile shear load (T's load) through the Taguchi Design of Experiment (DoE), which takes into account welding current, gas flow rate, and electrode diameter as primary parameters. This study evaluates T's load and hardness across the welding zone, which includes the heat-affected zone (HAZ) and base metal. The study was conducted using a Stahlweld inverter welding machine operating at 220 V/50 Hz, and a maximum T's load of 1545.1 kgf was achieved in the fourth iteration. The optimization of T's load was carried out using SN ratio analysis and involved setting the welding current to level II, gas flow rate to level I, and electrode diameter to level II following the Taguchi DoE design. The hardness peaks in the weld area decreased in the HAZ and reached their lowest point in the base metal. These findings provide valuable insights into optimizing TIG welding parameters for thin stainless steel 304 materials, which supports Sustainable Development Goal 9 (industry, innovation, and infrastructure).

Downloads

References

Ahmad, A. and Alam, S. (2019) ‘Parametric Optimization Of TIG Welding Using Response Surface Methodology’, in Materials Today: Proceedings. 9th International Conference of Materials Processing and Characterization, ICMPC-2019, Andhra Pradesh, India: Gokaraju Rangaraju Institute Of Engineering and Technology (9th International Conference of Materials Processing and Characterization, ICMPC-2019), pp. 3071–3079.

Al-Sabur, R. (2021) ‘Tensile Strength Prediction Of Aluminium Alloys Welded By FSW Using Response Surface Methodology – Comparative Review’, in Materials Today: Proceedings. Second International Conference on Aspects of Materials Science and Engineering (ICAMSE 2021), Chandigarh, India: Panjab University (Second International Conference on Aspects of Materials Science and Engineering (ICAMSE 2021)), pp. 4504–4510.

Amar et al. (2024) ‘Enhancing TIG Welding Parameters For Direct Tensile Load (DT-load) On Various Steel Thicknesses’, Jurnal Polimesin, 22(1), pp. 112–119.

ANSI (2012) ‘JIS G 4305:2012 - Cold-rolled stainless steel plate, sheet and strip’. ANSI. Available at: https://webstore.ansi.org/standards/jis/jis43052012 (Accessed: 13 July 2023).

Armansyah and Chie, H.H. (2018) ‘Optimization of Process Parameters on Tensile Shear Load of Friction Stir Spot Welded Aluminum Alloy (Aa5052-H112)’, SINERGI, 22(3), pp. 185–192.

ASME (2023) BPVC Section II-Materials Part C-Specifications for Welding Rods, Electrodes & Filler Metals - Specification for titanium and titanium-alloy welding electrodes and rods. Available at: https://www.asme.org/codes-standards/find-codes-standards/bpvc-iic-bpvc-section-ii-materials-part-c-specifications-welding-rods-electrodes-filler-metals/2023/print-book (Accessed: 11 July 2023).

AWS (1998) ‘AWS A5.12/A5.12M-98 (R2007) - Specification for Tungsten and Tungsten-Alloy Electrodes for Arc Welding and Cutting’. Available at: https://webstore.ansi.org/standards/aws/awsa51212m98r2007 (Accessed: 11 June 2023).

Das, T., Das, R. and Paul, J. (2020) ‘Resistance Spot Welding Of Dissimilar AISI-1008 Steel/Al-1100 Alloy Lap Joints With A Graphene Interlayer’, Journal of Manufacturing Processes, 53, pp. 260–274.

Datta, R. et al. (2002) ‘Weldability Characteristics Of Shielded Metal Arc Welded High Strength Quenched And Tempered Plates’, Journal of Materials Engineering and Performance, 11(1), pp. 5–10.

Endramawan, T. and Sifa, A. (2018) ‘Non Destructive Test Dye Penetrant and Ultrasonic on Welding SMAW Butt Joint with Acceptance Criteria ASME Standard’, in IOP Conference Series: Materials Science and Engineering. 2nd International Conference on Innovation in Engineering and Vocational Education, Manado, Indonesia: Universitas Pendidikan Indonesia, p. 012122.

Ghazali, F.A. et al. (2019) ‘Three Response Optimization of Spot-Welded Joint Using Taguchi Design and Response Surface Methodology Techniques’, in M. Awang (ed.) The Advances in Joining Technology. Singapore: Springer, pp. 85–95.

Heydari, H. and Akbari, M. (2020) ‘Investigating The Effect Of Process Parameters On The Temperature Field And Mechanical Properties In Pulsed Laser Welding Of Ti6Al4V Alloy Sheet Using Response Surface Methodology’, Infrared Physics & Technology, 106, p. 103267.

Jeong, H. et al. (2017) ‘Numerical Analysis Of Weld Pool For Galvanized Steel With Lap Joint In GTAW’, Journal of Mechanical Science and Technology, 31(6), pp. 2975–2983.

Khoirudin et al. (2023) ‘Optimization of S-EDM Process Parameters on Material Removal Rate using Copper Electrodes’, Jurnal Polimesin, 21(1), pp. 17–20.

Kobayashi, K. et al. (2004) ‘Practical Application of High Efficiency Twin-Arc TIG Welding Method (Sedar-TIG) for PCLNG Storage Tank’, Welding in the World, 48(7), pp. 35–39.

Kotu, V. and Deshpande, B. (2018) ‘Chapter 4: Classification’, in Data Science: Concepts and Practice. USA: Morgan Kaufmann, pp. 65–163.

Krinninger, M. et al. (2017) ‘On the Influence of Different Parameters on the Characteristic Cutting Surface when Shear Cutting Aluminum’, in Procedia CIRP. Manufacturing Systems 4.0 – Proceedings of the 50th CIRP Conference on Manufacturing Systems (Manufacturing Systems 4.0 – Proceedings of the 50th CIRP Conference on Manufacturing Systems), pp. 230–235.

Media, P.K.C. (2018) Industri Penggorengan Raksasa Asal ‘Gang Dag Deg Dog’ Bandung Tembus Pasar Luar Negeri. Available at: https://www.kompasiana.com/dennysuryadharma/5a9ab7bfdd0fa8392b414872/penggorengan-raksasa-asal-gang-dag-deg-dog-bandung (Accessed: 12 March 2023).

Montgomery, D.C. (2010) Design and Analysis of Experiments, Minitab Manual. 7th edn. USA: John Wiley & Sons. [Print].

Muthu, P. (2019) ‘Optimization of the Process Parameters of Resistance Spot Welding of AISI 316l Sheets Using Taguchi Method’, Mechanics and Mechanical Engineering, 23, pp. 64–69.

Nettleton, D. (2014) ‘Chapter 6 - Selection of Variables and Factor Derivation’, in D. Nettleton (ed.) Commercial Data Mining. Boston: Morgan Kaufmann, pp. 79–104.

Nurisna, Z. and Setiawan, E. (2020) ‘Pengaruh Filler Pada Pengelasan Tig Baja Karbon dan Stainless Steel 316l Terhadap Sifat Mekanik’, Quantum Teknika : Jurnal Teknik Mesin Terapan, 1(2), pp. 95–99.

Prabha, S. et al. (2021) ‘Plant-Derived Silica Nanoparticles And Composites For Biosensors, Bioimaging, Drug Delivery And Supercapacitors: A Review’, Environmental Chemistry Letters, 19(2), pp. 1667–1691.

Ragavendran, M. et al. (2017) ‘Optimization of hybrid laser – TIG welding of 316LN steel using response surface methodology (RSM)’, Optics and Lasers in Engineering, 94, pp. 27–36.

Reddy, G.N. and VenkataRamana, M. (2018) ‘Optimization Of Process Parameters In Welding Of Dissimilar Steels Using Robot TIG Welding’, in IOP Conference Series: Materials Science and Engineering. International Conference on Recent Advances in Materials, Mechanical and Civil Engineering, Hyderabad, India: Trans Tech Publications, p. 012096.

Samiuddin, M. et al. (2021) ‘Investigation On The Process Parameters Of TIG-Welded Aluminum Alloy Through Mechanical And Microstructural Characterization’, Defence Technology, 17(4), pp. 1234–1248.

Shrivas, S.P. et al. (2020) ‘Investigation Of TIG Welding Parameters To Improve Strength’, in Materials Today: Proceedings. 10th International Conference of Materials Processing and Characterization, Mathura, India: GLA University (10th International Conference of Materials Processing and Characterization), pp. 1897–1902.

Singh, N.K. and Vijayakumar, Y. (2012) ‘Application Of Taguchi Method For Optimization Of Resistance Spot Welding Of Austenitic Stainless Steel AISI 301L’, Innovative Systems Design and Engineering, 3(10), p. 49.

Sirohi, S. et al. (2023) ‘Dissimilar Autogenous TIG Joint Of Alloy 617 And AISI 304H Steel For AUSC Application’, Heliyon, 9(9), p. e19945.

Siswanto, A.P. et al. (2022) ‘Response Surface Methodology For Synthesis Of Bio-Jet Fuel From Waste Cooking Oil Using Agitated Ozone Treatment’, in Materials Today: Proceedings. 2nd International Conference on Chemical Engineering and Applied Sciences, Semarang, Indonesia: Universitas Diponegoro (2nd International Conference on Chemical Engineering and Applied Sciences), pp. S346–S348.

Sukarman et al. (2020) ‘Analisis Pengaruh Radius Dies Terhadap Springback Logam Lembaran Stainless-Steel Pada Proses Bending Hidrolik V-Die’, Jurnal Teknologi, 12(2), pp. 123–132.

Sukarman, Shieddieque, A.D., et al. (2021) ‘Optimization of Powder Coating Process Parameters in Mild Steel (SPCC-SD) To Improve Dry Film Thickness’, Journal of Applied Engineering Science, 19(2), pp. 475–482.

Sukarman, Abdulah, A., et al. (2021) ‘Optimization Of The Resistance Spot Welding Process Of SECC-AF And SGCC Galvanized Steel Sheet Using The Taguchi Method’, SINERGI, 25(3), pp. 319–328.

Sukarman, Khoirudin, et al. (2023) ‘Optimal Tensile-Shear Strength Of Galvanized/Mild Steel (SPCC-SD) Dissimilar Resistance Spot Welding Using Taguchi DOE’, Jurnal Teknologi, 85(4), pp. 167–177.

Sukarman, Triyono, et al. (2023) ‘Tensile Shear Load In Resistance Spot Welding Of Dissimilar Metals: An Optimization Study Using Response Surface Methodology’, Mechanical Engineering for Society and Industry, 3(2), pp. 66–77.

Sukarman and Abdulah, A. (2020) ‘Optimasi Single Response Proses Resistance Spot Welding Pada Penggabungan Baja Beda Material Menggunakan Metode Eksperimental Taguchi’, MULTITEK INDONESIA, 14(2), pp. 69–79.

Uijl, N.D. et al. (2012) ‘Performance of Tensile Tested Resistance Spot and Laser Welded Joints at Various Angles’, Welding in the World, 56(11), pp. 143–152.

Venkatesan, G., Muthupandi, V. and Justine, J. (2017) ‘Activated TIG Welding Of AISI 304L Using Mono- And Tri-Component Fluxes’, The International Journal of Advanced Manufacturing Technology, 93(1), pp. 329–336.

Vimal, K.E.K., Vinodh, S. and Raja, A. (2017) ‘Optimization Of Process Parameters Of SMAW Process Using NN-FGRA From The Sustainability View Point’, Journal of Intelligent Manufacturing, 28(6), pp. 1459–1480.

Widyianto, A., Baskoro, A.S. and Kiswanto, G. (2022) ‘Investigation on Weld Characteristic, Welding Position, Microstructure, and Mechanical Properties in Orbital Pulse Current Gas Tungsten Arc Welding of AISI 304L Stainless Steel Pipe’, IJTech - International Journal of Technology, 13(3), pp. 473–483.

Wirajaya, Y.M., Nugroho, N.Y. and Suwasono, B. (2021) ‘Holding Time pada Sifat Fisik Pengelasan SMAW Baja ASTM-A36 melalui Uji Penetran’, Jurnal Jaring SainTek, 3(2), pp. 45–50.

Wu, H. et al. (2019) ‘Research Advances In High-Energy TIG Arc Welding’, The International Journal of Advanced Manufacturing Technology, 104(1), pp. 391–410.

Xie, Y. et al. (2018) ‘Characterization Of Keyhole Gas Tungsten Arc Welded AISI 430 Steel And Joint Performance Optimization’, The International Journal of Advanced Manufacturing Technology, 99(1), pp. 347–361.