Analisis Implementasi Komunikasi Modbus TCP/IP dalam Penerapan Visualisasi Data Hasil Produksi pada Sistem Andon Line Production

Analysis of the Implementation of Modbus TCP/IP Communication in the Application of Production Data Visualization in the Andon Line Production System

DOI:

https://doi.org/10.35814/asiimetrik.v5i1.3791Keywords:

Andon, Modbus, TCP/IP, PLC, real timeAbstract

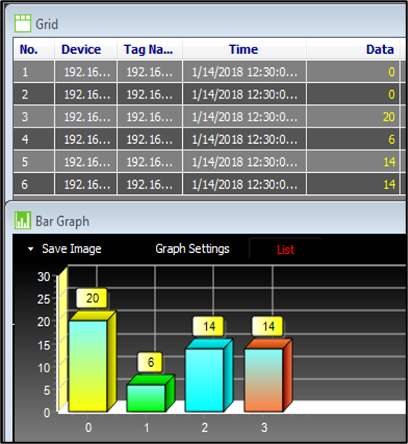

Andon refers to an information system aimed at management, maintenance, planners, or other workers regarding quality, process, or quantity issues. To support accurate data communication, a reliable protocol and high precision are required. The Modbus TCP/IP protocol is compatible with Andon systems. This study aims to analyze the implementation of Modbus TCP/IP communication in the application of production data visualization in online production systems. At a certain distance, the antenna's data must display the data's precision in real time. The average data transfer time at the farthest distance tested, 50 meters, was 0.0043 seconds, indicating that the longer the distance between the client and server, the longer the waiting time tends to be, but does not exceed 0.01 seconds if it does not affect production activities. These results are still pertinent to the information required by the organization.

Downloads

References

Banerji, S. (2013) Study and Development of a Data Acquisition & Control (DAQ) System using TCP/Modbus Protocol. Under West Bengal University of Technology.

Budiyarto, A. dkk. (2020) ‘Desain Implementasi Andon untuk Production Monitoring System Berbasis Internet of Thing’, CESS (Journal of Computer Engineering, System and Science), 5(1), hal. 89–97.

Fang, Y., Han, X. dan Han, B. (2013) ‘Research and Implementation of Collision Detection Based on Modbus Protocol.’, Journal of Engineering Science & Technology Review, 6(1), hal. 91–96.

Mulyadi, I. H. dkk. (2021) ‘Modul Komunikasi Modbus RTU over RS485 Berbasis Arduino’, Journal of Applied Electrical Engineering, 5(1), hal. 26–29.

Narayan, L. P. dan Anshika (2015) ‘Data acquisition of solar power plant using scada system’, Int. J. Eng. Trends and Technol, 23(4), hal. 189–194.

Riyanto, A.G.P., Fuadi, A.Z. dan Murti, M.A. (2020) ‘Andon System using Industrial IoT for Controlled Production Line by conventional PLC’, International Journal of Engineering Research & Technology (IJERT), 9(9), hal. 95–99.

Salem, F.A. dan Mahfouz, A.A. (2016) ‘Mechatronics Subsystems, Classification, Role, Selection Criteria and Synergistic Integration in Overall System Design’, American Journal of Educational Science, 2(3), hal. 16–28.

Sangolli, S. dan Baligar, V.P. (2015) ‘Implementation of Modbus Protocol on Distributed Supervisory Control and Data Acquisition for Industrial Process’, International Journal of Engineering Research & Technology (IJERT), 4(7), hal. 1079–1082.

Setioko, D.A., Murti, M.A. dan Sumaryo, S. (2019) ‘Perancangan Sistem Andon Nirkabel Berbasis Internet of Things (IoT) menggunakan PLC dan Raspberry Pi’, in Seminar Nasional Teknologi Komputer & Sains (SAINTEKS). Seminar Nasional Teknologi Komputer & Sains (SAINTEKS), Medan: STMIK Budi Darma & STIKOM Tunas Bangsa, hal. 202–206.

Susanto, A. (2017) ‘Modul Programmable Logic Controller (PLC) Berbasis Arduino Severino’, Jurnal Edukasi Elektro, 1(2), hal. 99–109.

Widiyanto, W., Sumbodo, W. dan Al Janan, D.H. (2012) ‘Analisis Perancangan dan Pembuatan Program PLC Pembacaan Encoder Pada Sistem Robot Record and Replay’, Journal of Mechanical Engineering Learning, 1(1), hal. 1–9.

Wojakowski, P. (2015) ‘Plant performance calculation in automotive industry using Andon system’, Research in Logistics & Production, 5(4), hal. 361–370.