The Effect of V-Bending Parameters Utilizing Electrolytic Zinc-Coated Steel Sheet (SECC) Material

Pengaruh Variasi V-Dies Bending Angle pada Material Electrolytic zinc-coated Steel Sheet (SECC)

DOI:

https://doi.org/10.35814/asiimetrik.v5i1.3937Keywords:

bending force, electrolytic zinc-coated, spring-back, spring-go, v-dies bendingAbstract

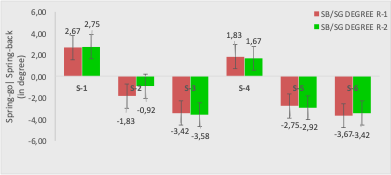

This study discusses the phenomenon of spring-back and spring-go in the bending kinematic forming using V-bending dies process and Electrolytic zinc-coated steel sheet (SECC/JIS G 3313) material. The zinc layer on the galvanized steel surface should not be damaged during the material forming process. The zinc layer on the galvanized steel sheet will affect the metal forming process. This study uses an experimental design with four input parameters, namely v-die opening L (mm), punch angle (degree), punch speed (mm/minutes), and bending force (kN). The smallest spring-back was obtained in the 4th test sample: the v-die opening of 35 mm, the punch angle of 40o, the punch speed of 30 mm/minute, and the bending force of 7.50 kN. The minor spring-back degree was 1.67o. Meanwhile, the smallest spring-go obtained in the second sample, namely the v-die opening of 30 mm, the punch angle of 50o, the punch speed of 40 mm/minute, and the bending force of 7.00 kN, the minor spring-go degree of 0.92o was obtained. These results show that the best spring-back degree for SECC/JIS G 3313 material is obtained when the bending process is performed with the v-die bending parameter of 30 mm, punch angle of 50o, punch speed of 40 mm/minute, and bending force of 7.00 kN.

Downloads

References

Ahmed, G.S. et al. (2014) ‘Experimental evaluation of springback in mild steel and its validation using LS-DYNA’, Procedia materials science, 6, pp. 1376–1385.

Altan, T. (1998) Metal forming handbook. Springer [Print].

Altan, T. and Tekkaya, A.E. (2012) Sheet metal forming: fundamentals. ASM International [Print].

BSN, - Badan Standarisasi Nasional (2004) SNI 07-7033-2004: Galvanisasi (hot-dip galvanized) pada besi dan baja fabrikasi - Spesifikasi dan metode pengujian, Detail SNI. Available at: http://sispk.bsn.go.id/SNI/DetailSNI/-CUSTOMER VALUE- [Online] (Accessed: 8 May 2022).

Gautam, V. and Kumar, D.R. (2018) ‘Experimental and numerical investigations on springback in V-bending of tailor-welded blanks of interstitial free steel’, Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 232(12), pp. 2178–2191.

JAS, - Japanese Standards Association (1998) ‘JIS G 3313: Electrolytic zinc-coated steel sheet and coils’. Japanese Standards Association (JAS) [Print].

Kan, H. and Hailing, Z. (2011) ‘A springback reduction method for sheet metal bending’, in 2011 International Conference on Mechatronic Science, Electric Engineering and Computer (MEC). 2011 International Conference on Mechatronic Science, Electric Engineering and Computer (MEC), Jilin, China: IEEE, pp. 617–620.

Khoirudin, K. et al. (2021) ‘A report on metal forming technology transfer from expert to industry for improving production efficiency’, Mechanical Engineering for Society and Industry, 1(2), pp. 96–103.

Khoirudin, K. et al. (2022) ‘Analisis Fenomena Spring-Back/Spring-Go Factor Pada Lembaran Baja Karbon Rendah Menggunakan Pendekatan Eksperimental’, Jurnal Teknologi, 14(1), pp. 27–38.

Leu, D.-K. and Zhuang, Z.-W. (2016) ‘Springback prediction of the vee bending process for high-strength steel sheets’, Journal of Mechanical Science and Technology, 30(3), pp. 1077–1084.

Özdemir, M., Dilipak, H. and Bostan, B. (2020) ‘Numerically modeling spring back and spring go amounts and bending deformations of Cr-Mo alloyed sheet material’, Materials Testing, 62(12), pp. 1265–1272.

Özdin, K. et al. (2014) ‘Investigation of Spring-Back and Spring-Go of AISI 400 S Sheet Metal in" V" Bending Dies Depending on Bending Angle and Punch Radius’, in Applied Mechanics and Materials. Trans Tech Publ, pp. 549–553.

Phanitwong, W., Sontamino, A. and Thipprakmas, S. (2013) ‘Effects of part geometry on spring-back/spring-go feature in U-bending process’, in Key Engineering Materials. Trans Tech Publ, pp. 100–107.

Rahardja, I.B. et al. (2020) ‘Analisis Pengaruh Radius Bending Pada Proses Bending Menggunakan Pelat SPCC-SD Terhadap Perubahan Struktur Mikro’, Jurnal Teknik Mesin Mechanical Xplore, 1(1), pp. 1–10.

Su, C. et al. (2017) ‘Research on roll-forming bending angle distribution function based on five boundary conditions’, Journal of Mechanical Science and Technology, 31(7), pp. 3445–3453.

Suchy, I. (2006) Handbook of Die Design. 2nd edn. McGraw-Hill Education [Print].

Sukarman, S. et al. (2021) ‘Optimization of the resistance spot welding process of secc-af and sgcc galvanized steel sheet using the taguchi method’, Sinergi, 25(3), pp. 319–328.

Thipprakmas, S. (2020) ‘Spring-back factor applied for V-bending die design’, Journal of Advanced Mechanical Design, Systems, and Manufacturing, 14(3), pp. JAMDSM0037–JAMDSM0037.

Troive, L. et al. (2018) ‘Springback compensation for a vehicle’s steel body panel’, International Journal of Computer Integrated Manufacturing, 31(2), pp. 152–163.

Wahed, M.A. et al. (2020) ‘Parameter optimisation in V-bending process at elevated temperatures to minimise spring back in Ti-6Al-4V alloy’, Advances in Materials and Processing Technologies, 6(2), pp. 350–364.