Perancangan Mesin Pembuat Tepung Jagung Kapasitas 5 kg/jam dengan Metode Pahl dan Beitz

Design of Corn Flour Machine with 5 kg/hour Capacity using Pahl and Beitz Methods

DOI:

https://doi.org/10.35814/asiimetrik.v5i1.4143Keywords:

design, Pahl & Beitz, sheller, flour, cornAbstract

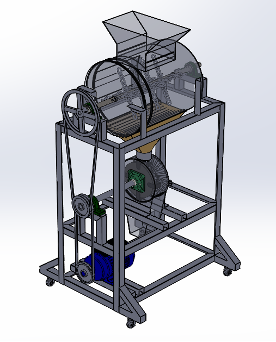

Corn is among the economic prospects supported by the expansion of the feed and food industries. To preserve corn yields, it can be processed into semi-finished products like corn flour. This paper discusses the design of a machine used to manufacture corn flour. Corn flour is the product that can be produced by the machine. The Pahl & Beitz design method is used to develop concepts. SOLIDWORKS Education Version 2019 is the software used to create three-dimensional images. The concept design utilizing the Pahl and Beitz method yields the selection of one concept variant with a weighting value of 4.82. The design of a corn flour making machine with engine dimensions of 800 mm x 450 mm x 1,500 mm uses a 220 V electric motor with a power of 1.5 hp and a rotational speed of 1400 rpm; the diameter of the shaft shaft is 30 mm, and the diameter of the shell shaft is 25 mm; the transmission used is a set of pulleys measuring 5 inches and 10 inches and a v-belt type A measuring 48 inches and The used bearings are of the UCP205, UCP206, and UCF206 types; the corn-shelling method employs a chain; the paddle for flour employs a diskmill; and the flour sieves have a 1 mm diameter hole. The frame is comprised of 40 mm by 40 mm angle iron; based on the results of the frame simulation, the maximum stress of the components is still less than the material's yield stress.

Downloads

References

Ariyani, S.B. dan Asmawit (2016) ‘Penggunaan Tepung Jagung Kalimantan Barat sebagai Bahan Baku Pembuatan Mie Kering’, Jurnal Dinamika Penelitian Industri, 27(2), hal. 76–81.

Armanto, E. dkk. (2020) ‘Alat Perontok Jagung Bagi Kelompok Petani Desa Prigi Kecamatan Kedungjati Kabupaten Grobogan’, in Prosiding Seminar Hasil Penelitian dan Pengabdian Masyarakat. Seminar Nasional Hasil Penelitian dan Pengabdian Masyarakat Polines, Politeknik Negeri Semarang: Politeknik Negeri Semarang, hal. 634–640.

Claudia, R. dkk. (2015) ‘Pengembangan Biskuit Dari Tepung Ubi Jalar Oranye (Ipomoea Batatas L.) Dan Tepung Jagung (Zea Mays) Fermentasi: Kajian Pustaka’, Jurnal Pangan dan Agroindustri, 3(4), hal. 1589–1595.

Dahlan, D. (2012) Elemen mesin. Jakarta: Penerbit Citra Harta Prima [Cetak].

Fitriyanti, S. (2017) ‘Kajian Potensi Mie Berbahan Baku Jagung’, AGRISAINS, 3(01), hal. 28–32.

Malawat, S. (2015) ‘Beberapa varietas jagung lokal dan prospek pengembangan produk olahannya di Kabupaten Maluku Tenggara Barat’, in Seminar Nasional Serealia. Seminar Nasional Serealia (2015), hal. 533–543.

Nugraha, D.S. dan Suteki, S. (2018) ‘Politik Hukum Penanganan Konflik Perkebunan oleh Pemerintah yang Berkeadilan Sosial’, Kanun Jurnal Ilmu Hukum, 20(1), hal. 103–122.

Pahl, G. dan Beitz, W. (2013) Engineering Design: A Systematic Approach. 2nd edn. London: Springer Science & Business Media [Cetak].

Saputra, B.R. (2018) ‘Perancangan Mesin Perontok Jagung Dengan Kapasitas Produksi 300 Kg/Jam’, Jurnal Konversi Energi dan Manufaktur, 5(1), hal. 7–14.

Sifa, A. dkk. (2020) ‘Perancangan Mesin Katrol untuk Mobilitas Mesin Pelontar Pakan Ikan’, in Prosiding Industrial Research Workshop and National Seminar. The 11th Industrial Research Workshop and National Seminar, Bandung: Politeknik Negeri Bandung, hal. 228–233.

Suwandi, A. dkk. (2021) ‘Perancangan Mesin Pembuka Kaleng Aerosol untuk Kategori Limbah Bahan Berbahaya dan Beracun (B3)’, Jurnal Teknologi, 13(2), hal. 115–128.

Yaqien, M.A. (2015) ‘Analisa Kebutuhan Material Dan Jenis Proses Produksi berdasarkan Desain Mesin Peniris Dan Pencampur Bumbu Makanan Ringan’, Jurnal Rekayasa Mesin, 3(1), hal. 63–68.