Pengaruh Campuran Thinner Terhadap Daya Rekat dan Ketebalan Lapisan Hasil dari Alat Custom Refill Cat Semprot

Influence of Thinner Addition in Coating Adhesion and Thickness was filled by Custom Spray Paint Refill Equipment

DOI:

https://doi.org/10.35814/asiimetrik.v5i1.4226Keywords:

functional test, custom refill, spray coating, adhesion, thicknessAbstract

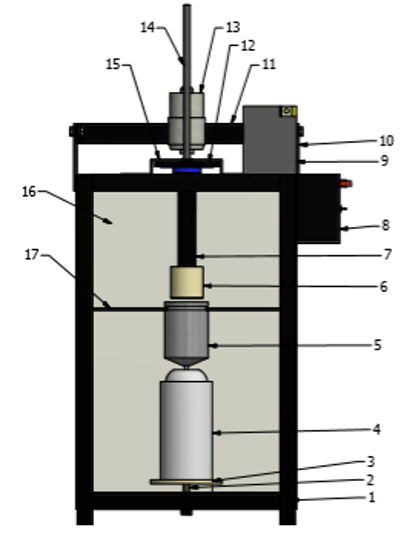

A custom spray coating refill equipment has been designed and fabrication. For this reason, it is necessary to trial the equipment that has been made. This study aims to determine the performance of custom spray coating refill equipment. For a comparison parameter, coating and thinner mixture variations were conducted to determine the adhesion and thickness of the coating layer formed. The coating used in this experiment was Nitrocellulose (NC) and Polyurethane (PU) thinner. The ratio of coating and thinner mixture used are 1:1.5, 1:2, and 1:2.5. After mixing, the mixture was put into the sprayer using custom spray paint refill equipment. The mixture of coating and thinner was sprayed onto the SPCC steel plate. To measure, the adhesion and thickness of the coating layers, a cross-cut tool (according to ASTM-D3359) and a thickness gauge (according to the ASTM-AMT15) were carried out respectively. It seems the spray paint refill equipment was functioning properly. This is due to the quality of the coating layers having good adhesion, shown by all specimens getting 5B classification (0% not peeled off). Moreover, an increase in the thinner composition is lead to a decrease in the coating thickness.

Downloads

References

Al Dzikri, D. dan Anjani, R.D. (2022) ‘Pengaruh Variasi Temperature Pengeringan Powder Coating Terhadap Daya Rekat Lapisan Cat Pada Mild Steel ST37’, Jurnal Ilmiah Wahana Pendidikan, 8(21), hal. 53–63.

ASTM, - American Standard Testing and Material (2019) ‘ASTM E376-19: Standard Practice for Measuring Coating Thickness by Magnetic-Field or Eddy Current (Electromagnetic) Testing Methods’. ASTM International.

ASTM, - American Standard Testing and Material (2022) ‘ASTM D3359-22: Standard Test Methods for Rating Adhesion by Tape Test’. ASTM International.

Dwiyati, S.T. (2015) ‘Pengaruh Kadar Hardener Terhadap Kualitas Produk Pengecatan Plastik’, Jurnal Konversi Energi Dan Manufaktur, 2(2), hal. 65–72.

Harahap, J. (2018) ‘Efek Uraian Komposisi Cat Dan Jarak Penyemprotan Cat Pada Material H-Beam’, Teknobiz: Jurnal Ilmiah Program Studi Magister Teknik Mesin, 8(1), hal. 11–16.

Iman, H.I.N., Darsin, M. dan Sakura, R.R. (2019) ‘Analisis Ketebalan Lapisan pada Pengecatan Baja Karbon Rendah menggunakan Metode Respons Permukaan’, SINTEK JURNAL: Jurnal Ilmiah Teknik Mesin, 13(2), hal. 65–72.

Khasib, A. (2017) ‘Pengaruh Variasi Penggunaan Thinner Pada Campuran Cat Terhadap Kualitas Hasil Pengecatan’, Jurnal Pendidikan Teknik Mesin, 6(1), hal. 35–42.

Lestari, A.T., Darmawan, I.W. dan Nandika, D. (2016) ‘Pengaruh kondisi permukaan terhadap daya lekat lapisan pelindung’, Jurnal Ilmu dan Teknologi Kayu Tropis, 14(1), hal. 11–22.

Muljani, S. (2021) ‘Sosialisasi Sampah B3-RT di Masyarakat’, Jurnal Abdimas Teknik Kimia, 2(01), hal. 10–14.

Noor, R. dan Ewo, T. (2007) ‘Pengaruh Ketebalan Lapisan Terhadap Daya Lekat Cat’, Jurnal Ilmiah Pendidikan Teknik Mesin Universitas Pendidikan Indonesia, Bandung, 11(1), hal. 1–7.

Permana, F.I. dan Anwar, S. (2014) ‘Pengaruh kualitas thinner pada campuran cat terhadap hasil pengecatan’, Jurnal Teknik Mesin (JTM), 3(2), hal. 53–61.

Ramdani, L.E.S.A. (2022) ‘Pelatihan Pemanfaatan Sampah Anorganik Rumah Tangga Menjadi Karya Komersil’, Dedikasi: Jurnal Pengabdian kepada Masyarakat, 3(2), hal. 1–11.

Soegijono, B., Susetyo, F.B. dan Notonegoro, H.A. (2019) ‘Perilaku Ketahanan Korosi Komposit Coating Poliuretan/Silika/Karbon Pada Baja Karbon Rendah’, FLYWHEEL: Jurnal Teknik Mesin Untirta, V(1), hal. 57–59.

Sopiyan, Iqbal, M. dan Susetyo, F.B. (2022) ‘Pengaruh Variasi Temperatur Pengeringan Terhadap Daya Kilap Cat Pada Komponen Kendaraan Bermotor’, METALIK: Jurnal Manufaktur, Energi, Material Teknik, 1(1), hal. 16–21.

Supriyono, Mulyanto, T. dan Miftahuddin, M. (2019) ‘Analisis Pengaruh Suhu Pengovenan Terhadap Daya Rekat Dan Kekuatan Lapisan Pada Pengecatan Serbuk’, Presisi, 21(2), pp. 77–87.

Suwandi, A. et al. (2021) ‘Perancangan Mesin Pembuka Kaleng Aerosol Untuk Kategori Limbah Bahan Berbahaya Dan Beracun (B3)’, Jurnal Teknologi, 13(2), hal. 115–128.

Tyagita, D.A., Pratama, A.W. dan Aprianto, D.B. (2019) ‘Variasi kadar tiner dan temperatur pengeringan terhadap kualitas hasil pengecatan bodi kendaraan berbahan ABS’, J-Proteksion: Jurnal Kajian Ilmiah dan Teknologi Teknik Mesin, 4(1), hal. 11–15.

Yulliyanti, W., Susanty, D. dan Wahyono, W. (2019) ‘Perbandingan Laju Korosi Pada Material Steel Plate Cold Coil (SPCC) Yang Dilapisi Cat Dengan Resin Yang Berbeda’, JURNAL SAINS NATURAL, 6(1), hal. 16–20.