Analisis Kerusakan Pada Permukaan Roda Kereta Rel Listrik

Analysis of Damage on the Surface of the Wheel of Electric Rail Train

DOI:

https://doi.org/10.35814/asiimetrik.v5i1.4272Keywords:

damage to surfaces, wheels, block brakes, electric trainsAbstract

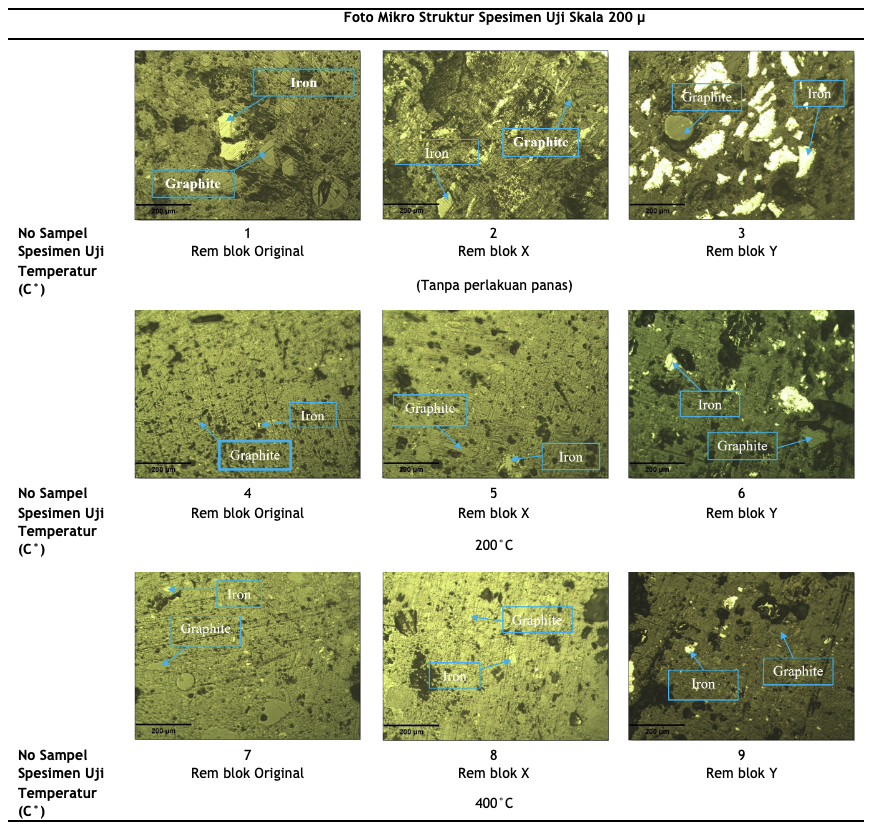

The wheels of electric rail cars are an essential component of rail transportation when they are in use. At the time of inspection, the technician discovered damage to the wheel's surface. This is due to the hardening of the brake block, which damages the wheel's surface. This research was conducted with the purpose of analyzing the causes of damage to the tread surface of the wheels and identifying a suitable replacement for the original brake block, which is no longer manufactured and has been replaced by imitation block brakes. so that further action can be taken to prevent similar occurrences in the future. Using the Vickers hardness test indentation method, the purpose of this study is to examine various heat treatments for determining a material's hardness level. The test results indicate that the VHN value increases with increasing heating temperature. The original specimen produced 99.5 VHN in the first test without heat treatment, while the X block brake produced 26.9 VHN and the Y brake produced 136.0 VHN. The second test with 200°C heat treatment on the original specimen yielded 96.8 VHN, 73.1 VHN from the X block, and 152.9 VHN from the Y block. In addition, the third test with 400°C heat treatment on the original specimen produced 92.4 VHN, 47.8 VHN for the X block brake, and 268.3 VHN for the Y block brake. The Vickers Hardness Test (VHN) hardness value is affected by heat treatment; the higher the heating value, the higher the hardness value of the remolok specimen.

Downloads

References

AS, H. (2012) Lokomotif dan kereta rel diesel di Indonesia. Depok: Ilalang Sakti Komunikasi [Cetak].

Ballew, B., Chan, B.J. dan Sandu, C. (2011) ‘Multibody dynamics modelling of the freight train bogie system’, Vehicle System Dynamics, 49(4), hal. 501–526.

Dieter, G.E. dan Bacon, D. (1976) Mechanical metallurgy. London: McGraw-hill New York [Cetak].

Firmansyah (2020) Uji Metalografi: Pengertian, Prosedur dan Standardnya. Available at: https://www.detech.co.id/uji-metalografi/ [Online] (Dikases: 5 Mei 2022).

Fitria, D. dan Pamuji, M. (2015) ‘Sistem Transmisi Elektrik Pada Lokomotif CC201 di Lubuk Linggau’, Jurnal Desiminasi Teknologi, 3(2), hal 166-173.

Jumardi dkk. (2020) ‘Perkembangan Transportasi Kereta Api di Jakarta’, Jurnal Pattingalloang, 7(1), hal. 40-48.

KAI, - PT. Kereta Api Indonesia (2017) Sekilas PT.KAI Commuter, Tentang Kami. Available at: https://www.krl.co.id/ [Online] (Diakses: 22 Juni 2022).

Lutiyatmi, L. dan Daryanto, T. (2013) ‘Karakteristik Produk Rem Blok Metalik Untuk Kereta Api Pada Industri Kecil Pengecoran Logam’, Jurnal Foundry, 3(2), hal. 18–23.

Rauf, F.A., Sappu, F.P. dan Lakat, A.M.A. (2018) ‘Uji Kekerasan Dengan Menggunaan Alat Microhardness Vickers Pada Berbagai Jenis Material Teknik’, Jurnal Tekno Mesin, 5(1), hal. 21–24.

Soejima, H. (2003) ‘Railway Technology in Japan —Challenges and Strategies’, Japan Railway & Transport Review, 36, hal. 4–13.

Sone, S. (2018) ‘Comparison of the Technologies of the Japanese Shinkansen and Chinese High-Speed Railways’, China’s High-Speed Rail Technology, 2018, hal. 67–87.

Sujatno, A. dkk. (2017) ‘Studi Scanning Electron Microscopy (SEM) untuk Karakterisasi Proses Oxidasi Paduan Zirkonium’, Jurnal Forum Nuklir, 9(1), hal. 44–50.

Supriyana, N. dan Kholidin, A. (2016) ‘Analisa tegangan poros roda gerbong kereta api dengan metode elemen hingga’, Simetris: Jurnal Teknik Mesin, Elektro dan Ilmu Komputer, 7(2), hal. 681–686.

Utami, H.P. (2007) Mengenal Cahaya dan Optik. 1st edn. Bekasi: Ganeca Exact [Cetak].

Widjatmaka, T. dan Prasetya, S. (2011) ‘Perancangan Dan Pembuatan Peralatan Laboratorium Pengkonversi Gambar Struktur Mikro Dari Mikroskop Ke Komputer Sebagai Sarana Praktikum Metalografi’, 10(3), hal. 217–281.