Desain dan Analisis Kekuatan Rangka Mesin Pres Batako Menggunakan Finite Element Method

Design and Strength Analysis of Brick Press Machine Frame using Finite Element Method

DOI:

https://doi.org/10.35814/asiimetrik.v5i2.4658Keywords:

mild steel, displacement, safety factor, dynamic load, simulationAbstract

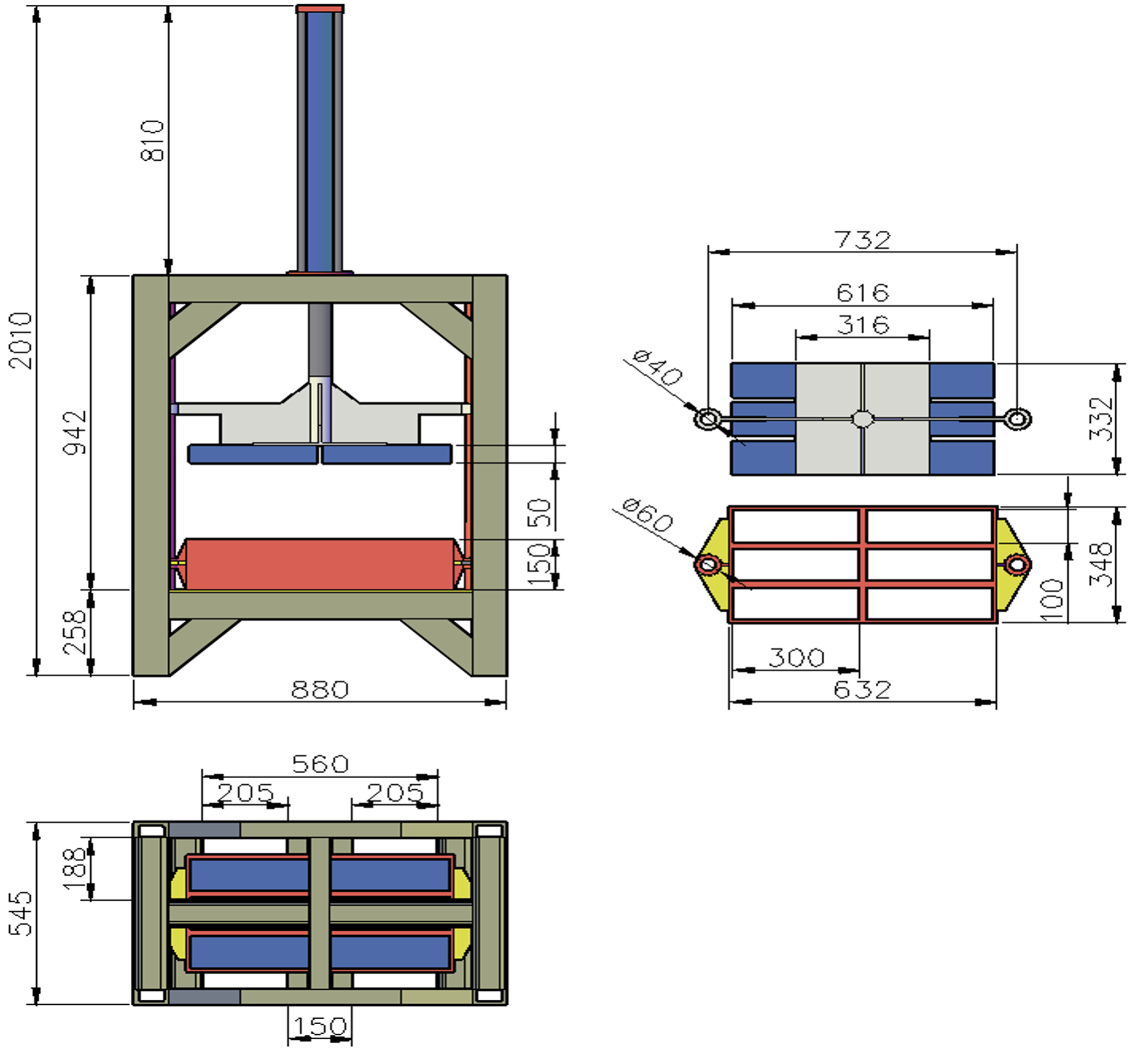

This study investigates the safety factor and stress in order to determine the utmost dynamic load the press machine frame can withstand. Dynamic loads occur because of the working mechanism of the press machine, which suppresses the brick components. Test simulation stress analysis using the computer program Inventor Professional Student 2023 with the finite element method in a material structure simulation test of a brick press machine frame with a dynamic load treatment the frame design model uses mild steel material with dimensions of 880 mm by 545 mm by 1200 mm. The variable loads are 700 kg, 1000 kg, and 1500kg. The simulation results show the displacement value at a load of 700 kg = 0,25 mm; 1000 kg = 0,36 mm; and 1500 kg = 0,54 mm. The von Mises stress value is 700 kg = 70,03 MPa; 1000 kg = 100,4 MPa; and 1500 kg = 150,9 MPa. The safety factor value is 700 kg = 2,96; 1000 kg = 2,06; and 1500 kg = 1,37. The simulation results show that the frame design of the brick press machine has a safety factor of 2,06 and can withstand a dynamic load of up to 1000 kg.

Downloads

References

Attorik, A.A. dkk. (2022) ‘Simulasi Dan Analisis Kekuatan Pembebanan Frame Pada Perancangan Mesin Press Bearing Manual Hydraulic Jack Menggunakan Autodesk Inventor’, Jurnal Vokasi Mekanika, 4(1), hal. 19–25.

Aufana, D., Kabib, M. dan Hidayat, T. (2019) ‘Perancangan Dan Simulasi Tegangan Frame Mesin Pengisian Curah Tembakau’, Jurnal Crankshaft, 2(2), hal. 9–16.

Daryanto, A. (2007) Eksperimen Dan Analisis Pemodelan Uji Tarik Plat Logam (Sheet Metal) Dengan Standar ASTM E 8M. Thesis. Universitas Muhammadiyah Surakarta.

Dobrovolsky, V. (1968) Machine Elements. Mir Publishers [Cetak].

Faraji, G., Kim, H.S. dan Kashi, H.T. (2018) Severe Plastic Deformation: Methods, Processing and Properties. Butterworth-Heinemann: Elsevier [Cetak].

Farshal, M.F., Nugroho, S. dan Umardani, Y. (2022) ‘Analisis kegagalan sprocket pada transmisi mobil Antawirya’, Jurnal Teknik Mesin Indonesia, 17(2), hal. 97–101.

Hamdani, A. dkk. (2020) ‘Perancangan Dan Simulasi Tegangan Rangka Mesin Pres Batako’, Jurnal Crankshaft, 3(2), hal. 1–6.

Henshall, G.A., Helling, D.E. dan Miller, A.K. (1996) ‘Improvements in the MATMOD Equations for Modeling Solute Effects and Yield-Surface Distortion’, in Unified Constitutive Laws of Plastic Deformation. Butterworth-Heinemann: Elsevier [Cetak].

Hu, J., Marciniak, Z. dan Duncan, J. (2002) Mechanics of Sheet Metal Forming. Butterworth-Heinemann: Elsevier [Cetak].

Marpaung, F., Wibowo, E.T. dan Harmadi, R. (2022) ‘Desain dan Analisis Tanki ISO LNG Kapasitas 40 feet Menggunakan Teknik Finite Element Analysis’, Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa Dan Inovasi, 4(2), hal. 163–170.

Megson, T.H.G. (2019) Structural and Stress Analysis - 4th Edition. Butterworth-Heinemann: Elsevier [Cetak].

Sukanto dan Adhe Anggry (2012) ‘Rancang Bangun Mesin Pengaduk Material Bahan Batako Berkapasitas 0,8 m3 Di Provinsi Kepulauan Bangka Belitung’, in STEMAN 2012. Seminar Nasional Rekayasa Dan Teknologi Manufaktur, Bandung: Politeknik Manufaktur Bandung (2012), hal. 1–7.

Suwandi, A. dkk. (2019) ‘Simulation-based Prediction of Structural Design Failure in Fishing Deck Machinery a Hydraulic Type with Finite Element Method’, in IC-AMME 2018. The 1st International Conference on Automotive, Manufacturing, and Mechanical Engineering (IC-AMME 2018), Indonesia: E3S Web of Conferences, hal. 01001–01008.

Syaukani, M. dkk. (2021) ‘Desain dan Analisis Mesin Press Komposit Kapasitas 20 Ton’, Journal of Science, Technology, and Visual Culture, 1(1), hal. 29–34.

Wibawa, L.A.N. dan Himawanto, D.A. (2018) ‘Analisis Ketahanan Beban Dinamis Material Turbin Angin Terhadap Kecepatan Putar Rotor (Rpm) Menggunakan Metode Elemen Hingga’, Simetris: Jurnal Teknik Mesin, Elektro dan Ilmu Komputer, 9(2), hal. 803–808.

Younis, W. (2019) Up and Running with Autodesk Inventor Simulation 2010 - 1st Edition. 1st edn. Butterworth-Heinemann: Elsevier [Cetak].

Yulianto, N. dan Winarso, R. (2012) ‘Analisa Tegangan Pada Rangka Prototype Kendaraan Buge Menggunakan Elemen Hingga’, Simetris: Jurnal Teknik Mesin, Elektro dan Ilmu Komputer, 2(1), hal. 10–18.