Usulan Rancangan Layout Gudang Menggunakan Metode Shared Storage pada PT. XYZ

Proposed Warehouse Layout Design using the Shared Storage Method at PT. XYZ

DOI:

https://doi.org/10.35814/asiimetrik.v5i2.4660Keywords:

warehouse, design layout, shared storage methodAbstract

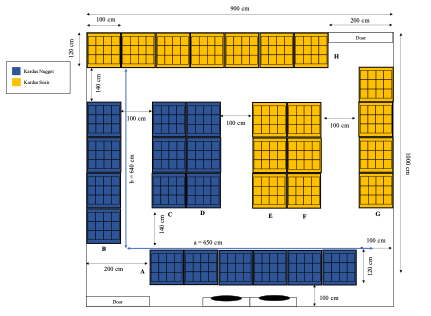

The company has a raw material warehouse to carry out its production process, but the warehouse needs to be optimized because employees experience limited access to raw materials and the current warehouse layout is still not optimal. This research was conducted to find out the proposed improvements to the raw material warehouse layout so that the company can optimize the function of the existing raw material warehouse within the company. The Shared Storage Method can be used in layout design by arranging storage areas according to the condition of the warehouse floor area. The shared storage method assists in optimizing product storage time so that you can find out when the product will enter and leave the warehouse storage area. The proposals obtained influenced increasing the previous warehouse capacity. There was an increase in capacity of 21.5%. The proposals obtained influenced increasing the previous warehouse capacity. The results of the research on the application of the design for the new layout, at one level, have a warehouse capacity of 33 pallets with ± 14 tons of product. However, by optimizing warehouse capacity by adding one level above it, the warehouse capacity can be doubled, namely 66 pallets with 28 tons of product with product placement between the first and second levels of the same level. The use of warehouse layouts is intended for new image layouts from this study.

Downloads

References

Amri, A., Bahri, S. dan Geni, P.L. (2021) ‘Perencanaan Ulang Tata Letak Gudang Material Bahan Baku Dengan Menggunakan Metode Shared Storage Dan Pendekatan Simulasi Pada PT. Aini Sejahtera’, Industrial Engineering Journal, 10(1), hal. 1–8.

Arifin, J. dan Pamungkas, T. (2019) ‘Perbaikan Tata Letak Gudang Dengan Menggunakan Metode Shared Storage Pada Perum Bulog Subdivre Karawang’, Jurnal Media Teknik dan Sistem Industri, 3(1), hal. 7–14.

Ekoanindiyo, F.A. dan Wedana, Y.A. (2012) ‘Perencanaan Tata Letak Gudang Penggunakan Metode Shared Storage Di Pabrik Plastik Kota Semarang’, Dinamika Teknik Industri, 6(1), hal. 46-57.

Fajri, A. (2021) ‘Perancangan Tata Letak Gudang Dengan Metode Systematic Layout Planning’, Jurnal Teknik Industri: Jurnal Hasil Penelitian dan Karya Ilmiah dalam Bidang Teknik Industri, 7(1), hal. 27–36.

Indah, D. Rosa dan Maulida, Z. (2018) ‘Pengendalian Persediaan Bahan Baku Pada PT. Aceh Rubber Industries Kabupaten Aceh Tamiang’, Jurnal Manajemen dan Keuangan, 7(2), hal. 157–157.

Juliana, H. dan Handayani, N.U. (2016) ‘Peningkatan Kapasitas Gudang Dengan Perancangan Layout Menggunakan Metode Class-Based Storage’, Jurnal Teknik Industri, 11(2), hal. 113-122.

Mulyati, E., Numang, I. dan Nurdiansyah, M.A. (2020) ‘Usulan Tata Letak Gudang Dengan Metode Shared Storage di PT Agility International Customer PT Herbalife Indonesia’, Jurnal Logistik Bisnis, 10(02), hal. 36–41.

Noor, I. (2018) ‘Peningkatan Kapasitas Gudang Dengan Redesign Layout Menggunakan Metode Shared Storage’, Journal of Industrial Engineering and Operation Management (JIEOM), 1(1), hal. 12–18.

Prasetyo, R.A., Herwanto, D. dan Kusnadi, K. (2021) ‘Usulan Penerapan Metode Shared Storage pada Tata Letak Stock di Gudang PT XYZ’, Go-Integratif : Jurnal Teknik Sistem dan Industri, 2(02), hal. 124–134.

Rahmadani, W.I. (2020) ‘Perancangan Ulang Tata Letak Gudang Menggunakan Metode Konvensional, Corelap Dan Simulasi Promodel’, Jurnal Optimasi Teknik Industri (JOTI), 2(1), hal. 13–18.

Rosihin, R. dkk. (2021) ‘Analisa Perbaikan Tata Letak Gudang Coil dengan Metode Class Based Storage’, Jurnal INTECH Teknik Industri Universitas Serang Raya, 7(2), pp. 166–172.

Santoso, P.S.A., Herlina, L. dan Febianti, E. (2016) ‘Usulan Tata Letak Gudang Produk Jadi Dengan Metode Shared Storage Dan Pendekatan Simulasi Di PT. Lotte Chemical Titan Nusantara’, Jurnal Teknik Industri Untirta, 4(3), hal. 1–8.