Analisis Kualitas Produk Toolbox Menggunakan Metode Seven Tools di PT. KSKB

Product Quality Analysis of Toolbox using Seven Tools Method at PT. KSKB

DOI:

https://doi.org/10.35814/asiimetrik.v5i2.4877Keywords:

defect, Kaizen Five-M checklist, quality improvement, seven toolsAbstract

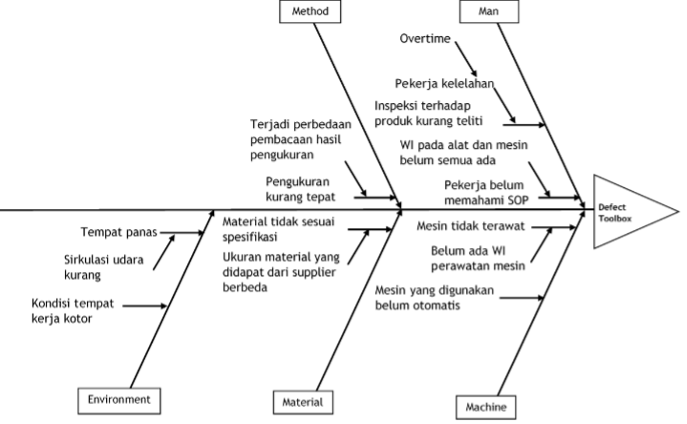

The rapid development of the industrial world has made it a necessity for companies to compete with their competitors. Therefore, companies must control the quality of their products well, one of which is by analyzing defective products. The purpose of this research is to analyze the level of defects in Toolbox products produced by PT KSKB and provide improvement suggestions to reduce the level of defects in PT KSKB Toolbox products. This research uses data on the number of productions and the number of defective products obtained through field observations and interview processes. The method used in this research is the Seven Tools and Kaizen Five-M Checklist method of improvement analysis. Based on the data processing results, there are three types of defects in Toolbox products: burrs, materials with holes, and cutting with no precision. The most frequent type of defect is burrs (an uneven surface of the object due to the working process), with a value of 52.12%. Meanwhile, from the analysis of the Kaizen Five-M Checklist, periodic training (training and OJT) needs to be conducted for employees, routine machine maintenance needs to be carried out, standard operating procedures need to be evaluated, and work areas need to be evaluated to create a safe and comfortable working environment so that the level of product defects can be reduced.

Downloads

References

Akbar, R., Rizqi, A.W. dan Hidayat, H. (2022) ‘Analisis Kecacatan Produk Meja Plywood Menggunakan Metode Seven Tools (Studi Kasus: Teaching Factory SMK Manbaul Ulum)’, SITEKIN: Jurnal Sains, Teknologi dan Industri, 19(2), hal. 195–202.

Devani, V. dan Oktaviany, M. (2021) ‘Usulan Peningkatan Kualitas Pulp Dengan Menggunakan Metode Seven Tools Dan New Seven Tools Di PT. IK’, Agrointek : Jurnal Teknologi Industri Pertanian, 15(2), hal. 521–536.

Dianto, K., Andesta, D. dan Fathoni, M.Z. (2022) ‘Analisis Keselamatan Dan Kesehatan Kerja Di Pekerjaan Fabrikasi Dengan Menggunakan Metode Hazards Identification And Risk Assesment Dan Pendekatan Fault Tree Analysis’, JUSTI (Jurnal Sistem dan Teknik Industri), 1(2), hal. 152–163.

Farchiyah, F. (2021) ‘Analisis Pengendalian Kualitas Spanduk Dengan Metode Seven Quality Control Tools (7 QC) pada PT. Fim Printing’, Tekmapro: Journal of Industrial Engineering and Management, 16(1), hal. 36–47.

Gusniar, I.N. dan Ramadhan, D.N. (2022) ‘Pengendalian Kualitas Menggunakan Seven Tools dan Kaizen pada Part PLG di PT Naratama Sayagai Indonesia’, Jurnal Serambi Engineering, 7(4), hal. 3655–3663.

Hamdani, D. (2020) ‘Pengendalian Kualitas Dengan Menggunakan Metode Seven Tools Pada PT X’, Jurnal Ekonomi, Manajemen dan Perbankan (Journal of Economics, Management and Banking), 6(3), hal. 139–143.

Hamdani, H., Wahyudin, W. dan Putra, C.G.G. (2021) ‘Analisis Pengendalian Kualitas Produk 4L45W 21 . 5 MY Menggunakan Seven Tools dan Kaizen’, Go-Integratif : Jurnal Teknik Sistem dan Industri, 2(2), hal. 112–123.

Hardono, J., Pratama, H. dan Friyatna, A. (2019) ‘Analisis Cacat Produk Green Tyre dengan Pendekatan Seven Tools’, Jurnal INTECH Teknik Industri Universitas Serang Raya, 5(1), hal. 1–6.

Haryanto, E. (2019) ‘Analisis Pengendalian Kualitas Produk Bos Rotor Pada Proses Mesin CNC Lathe Dengan Metode Seven Tools’, Jurnal Teknik, 8(1), hal. 69–77.

Irwati, D. dan Prasetya, D.I. (2020) ‘Mengurangi Cacat Color out Menggunakan Pendekatan Seven tools: Studi Kasus Industri Coloring Compound Plastic’, Jurnal Teknik Industri, 1(2), hal. 16–21.

Lutfiah, D. dkk. (2020) ‘Analisis pengendalian kualitas produk di ukm roti uci berdasarkan pendekatan six sigma dan metode kaizen pada tahap improve dalam six sigma’, in Prosiding Seminar Nasional Ilmu Teknik Dan Aplikasi Industri Fakultas Teknik Universitas Lampung. Seminar Nasional Hasil Penelitian Sains, Teknik dan Aplikasi Industri Fakultas Teknik Universitas Lampung, Lampung: Universitas Lampung, hal. 1–6.

Matondang, T.P. dan Ulkhaq, M.M. (2018) ‘Aplikasi Seven Tools untuk Mengurangi Cacat Produk White Body pada Mesin Roller’, Jurnal Sistem dan Manajemen Industri, 2(2), hal. 59–66.

Merjani, A. dan Kamil, I. (2021) ‘Penerapan Metode Seven Tools Dan PDCA (Plan Do Check Action) Untuk Mengurangi Cacat Pengelasan Pipa’, PROFISIENSI: Jurnal Program Studi Teknik Industri, 9(1), hal. 124–131.

Nursyamsi, I. dan Momon, A. (2022) ‘Analisa Pengendalian Kualitas Menggunakan Metode Seven Tools untuk Meminimalkan Return Konsumen di PT. XYZ’, Jurnal Serambi Engineering, 7(1), hal. 2701–2708.

Somadi, S., Priambodo, B.S. dan Okarini, P.R. (2020) ‘Evaluasi Kerusakan Barang dalam Proses Pengiriman dengan Menggunakan Metode Seven Tools’, Jurnal INTECH Teknik Industri Universitas Serang Raya, 6(1), hal. 1–11.

Suparjo, S. dan Afan, M.I. (2019) ‘Pengendalian Kualitas di PT XXX dengan Menggunakan Metode Seven Tools’, in Prosiding Seminar Nasional Sains dan Teknologi Terapan. Seminar Nasional Sains dan Teknologi Terapan, Surabaya: nstitut Teknologi Adhi Tama Surabaya, hal. 409–414.

Suwandi, A. dan Huda, M.A. (2011) ‘Penerapan Metode QC 7 Tools untuk Meningkatkan Kualitas Produk Stay Component Muffler’, TEKNOBIZ : Jurnal Ilmiah Program Studi Magister Teknik Mesin, 1(1), hal. 10–17.

Tannady, H. (2020) Pengendalian Kualitas. Jakarta: Graha Ilmu [Cetak].

Zakariya, Y., Mu’tamar, M.F.F. dan Hidayat, K. (2020) ‘Analisis Pengendalian Mutu Produk Air Minum dalam Kemasan Menggunakan Metode New Seven Tools (Studi Kasus di PT. DEA)’, Rekayasa, 13(2), hal. 97–102.