Development of Data Acquisition System on an Arduino-Based Tensile Test Machine for Composite Materials

Pengembangan Sistem Akuisisi Data pada Mesin Uji Tarik berbasis Arduino untuk Material Komposit

DOI:

https://doi.org/10.35814/asiimetrik.v5i2.4981Keywords:

load cell, logging time, bamboo composite, data acquisition, tensile test machineAbstract

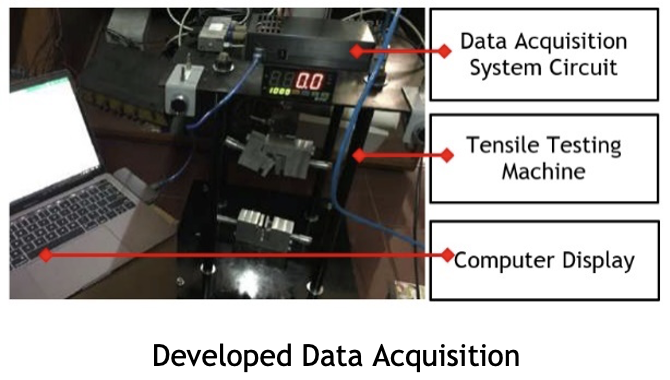

A tensile testing machine with a lower load capacity is needed to identify the mechanical properties of composite materials. Tensile testing machines for composite materials are available in the market but at high prices. Previously, using a pneumatic system, a tensile testing machine for composite materials with a maximum load of 2000N was developed. However, this tensile test machine still needs improvement because the display of eventuating forces is only in numbers, not yet including a test graph. Therefore, this study developed a prototype data acquisition system for a tensile test machine to record the test results in more detail, both numbers and graphs. This data acquisition system uses the Arduino Uno Microcontroller, which processes data from the load cell through the HX711 module intermediary. A tensile test was carried out using a bamboo fiber composite material to validate the results of testing the prototype of this data acquisition system. Furthermore, the test results data are compared with the results on the indicators of the existing tensile test machine. The test was carried out nine times with an average tensile force of 1.66 N/mm2, while the average tensile force on the tool indicator was 2.02 N/mm2. There is a difference in the average test results equal to 12%. This difference is a systematic error because nine experiments have shown the same trend, with standard error and standard deviation of 0.3368 and 0.1123, respectively. The systematic error is compensated through calibration between the load cell of the tensile test machine and a series of data acquisition systems based on Arduino Uno.

Downloads

References

Abedom, F. et al. (2021) ‘Development of Natural Fiber Hybrid Composites Using Sugarcane Bagasse and Bamboo Charcoal for Automotive Thermal Insulation Materials’, Advances in Materials Science and Engineering, 2021, p. e2508840.

Adriant, Z. et al. (2019) ‘The Effect of Mesh Size on Mechanical and Thermal Properties of Bamboo Composites’, JEMMME (Journal of Energy, Mechanical, Material, and Manufacturing Engineering), 4(2), pp. 63–72.

Arrizabalaga, J.H., Simmons, A.D. and Nollert, M.U. (2017) ‘Fabrication of an Economical Arduino-Based Uniaxial Tensile Tester’, Journal of Chemical Education, 94(4), pp. 530–533.

ASTM (2010) ‘Standard Test Method for Tensile Properties of Plastics’. ASTM International [Print].

Elanchezhian, C. et al. (2018) ‘Review on mechanical properties of natural fiber composites.’, in Materials Today: Proceedings. International Conference on Processing of Materials, Minerals and Energy, India: Elsevier, pp. 1785–1790.

Gellert, R. (2010) ‘8 - Inorganic mineral materials for insulation in buildings’, in M.R. Hall (ed.) Materials for Energy Efficiency and Thermal Comfort in Buildings. Woodhead Publishing (Woodhead Publishing Series in Energy), pp. 193–228.

Getu, D. et al. (2021) ‘Production and characterization of bamboo and sisal fiber reinforced hybrid composite for interior automotive body application’, in Materials Today: Proceedings. International Conference & Exposition on Mechanical, Material and Manufacturing Technology (ICE3MT), India: Elsevier, pp. 2853–2860.

Khalil, H.P.S.A. et al. (2012) ‘Bamboo fibre reinforced biocomposites: A review’, Materials & Design, 42, pp. 353–368.

Kurniawan, R.M. and Zariatin, D.L. (2019) ‘Perancangan Alat Uji Tarik Dengan Beban 2000 N Untuk Pengujian Material Komposit Alami’, in Prosiding Seminar Rekayasa Teknologi (SemResTek) 2019. Seminar Rekayasa Teknologi (SemResTek) 2019, Indonesia: Fakultas Teknik Universitas Pancasila, pp. 351–360.

Montgomery, D.C. (2019) Design and Analysis of Experiments. 10th edn. USA: John Wiley & Sons Inc. [Print].

Pandiatmi, P. et al. (2017) ‘Pembuatan mesin uji tarik kapasitas kecil: bagian data akuisisi’, Dinamika Teknik Mesin, 7(1), pp. 45–49.

Singh, S. et al. (2014) ‘Tensile and Flexural Behavior of Hemp Fiber Reinforced Virgin-recycled HDPE Matrix Composites’, in Procedia Materials Science. 3rd International Conference on Materials Processing and Characterisation (ICMPC 2014), India: Elsevier, pp. 1696–1702.

Truong, V.D. and Kim, D.J. (2021) ‘A review paper on direct tensile behavior and test methods of textile reinforced cementitious composites’, Composite Structures, 263, p. 113661.

Wiranata, A. et al. (2022) ‘Electromechanical tensile test equipment for stretchable conductive materials’, HardwareX, 11, p. e00287.

Zariatin, D.L., Kurniawan, R.M. and Ikhsan, N. (2021) ‘Pengembangan alat uji tarik dengan beban maksimal 2 kN’, Dinamika Teknik Mesin, 11(2), pp. 96–106.

Zheng, P. et al. (2020) ‘On the standards and practices for miniaturized tensile test – A review’, Fusion Engineering and Design, 161, p. 112006.