Analysis of Prototype Electric Car Chassis Construction using Aluminum Hollow 6061 Profiles using Inventor Software 2016

Analisis Bentuk Kontruksi Chassis Mobil Listrik Prototype Tipe Hollow Alumunium 6061 Menggunakan Software Inventor 2016

DOI:

https://doi.org/10.35814/asiimetrik.v5i2.4995Keywords:

prototype, von mises stress, displacement, safety factor, InventorAbstract

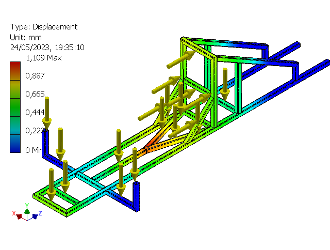

Vehicles are a means of transportation. Most vehicles use fossil fuels as an energy source. Fossil fuels will run out, so electricity is used as a substitute. Electric fuel is environmentally friendly and does not emit pollution. Making a prototype electric car, one of which is preparing a design and simulating it using software. This study aims to find the best 6061 hollow aluminum chassis model through static analysis using Autodesk Inventor software with the finite element analysis (FEA) method. This study compares three chassis models, namely chassis patterns H, X, and Y, which will be subjected to a static load test of 900 N, including the driver's load of 600 N. The values obtained are von Mises stress, displacement, and the safety factor. The dimensions of the chassis are 2,160 mm by 750 mm by 500 mm, with a thickness of 2 mm. The results can be concluded: the H-pattern chassis is the best and easier to design compared to the X and Y chassis. This chassis has a von Mises stress value of 84.47 MPa, a displacement value of 0.89 mm, and a safety factor of 3.20. Based on these results, the model H chassis is safe.

Downloads

References

Daryanto, D. and Tyassmadi, A.T. (2016) Dasar-Dasar Teknik Mobil. 1st edn. Jakarta: Bumi Aksara [Print].

Dudescu, M.C., Bere, P. and Neamțu, C. (2022) ‘Structural Analysis of An Electric Car Chassis By Numerical And Experimental Methods’, Acta Technica Napocensis - Series: Applied Mathematics, Mechanics, And Engineering, 65(4S), pp. 1103–1110.

Dwinanto, A.Y. and Muhammad, F.B. (2015) ‘Analisa Perbandingan Karakteristik Bodi dan Chassis pada Prototype Kendaraan Listrik’, Jurnal Rekayasa Mesin, 6(2), pp. 101–105.

Efendi, A. (2020) ‘Rancang Bangun Mobil Listrik Sula Politeknik Negeri Subang’, Jurnal Pendidikan Teknologi dan Kejuruan, 17(1), pp. 75–84.

Ellianto, M.S.D. and Nurcahyo, Y.E. (2020) ‘Rancang Bangun dan Simulasi Pembebanan Statik pada Sasis Mobil Hemat Energi Kategori Prototype’, Jurnal Engine: Energi, Manufaktur, dan Material, 4(2), pp. 53–58.

Fauzi, G. and Marsono (2021) ‘Analisis Statik Chassis Mobil Listrik Jenis Ladder Frame Berbahan Baja Holow Dengan Bantuan Software Solidworks’, in 2021: Prosiding Diseminasi FTI Genap. Diseminasi FTI, Bandung: Institut Teknologi Nasional Bandung, pp. 1–10.

Hasanuddin, I. et al. (2019) ‘Desain dan Analisis Rangka Mobil Listrik Malem Diwa X.2 Model Prototype Menggunakan Metode Elemen Hingga’, Jurnal Teknik Mesin, 7(1), pp. 10–14.

Keliky, S. (2014) ‘Kajian Pemilihan Material Bahan Rangka Body Pada Mobil Listrik’, TEKNOBIZ : Jurnal Ilmiah Program Studi Magister Teknik Mesin, 4(1), pp. 41–48.

Mulyadi, S. et al. (2022) ‘Analisis Tegangan Prinsipal Pada Chassis Mobil Listrik Tipe Prototype’, Elemen : Jurnal Teknik Mesin, 9(1), pp. 24–30.

Setiawan, M.A.A., Sujana, I. and Taufiqurrahman, M. (2021) ‘Simulasi Struktur Sasis Mobil Listrik Fakultas Teknik Menggunakan Finite Element Analysis (FEA)’, JTRAIN: Jurnal Teknologi Rekayasa Teknik Mesin, 2(2), pp. 118–122.

Shantika, T., Firmansjah, E.T. and Naufan, I. (2017) ‘Perancangan Chassis Type Tubular Space Frame Untuk Kendaraan Listrik’, POROS, 15(1), pp. 9–17.

Sihombing, I.N., Jokosiworo, S. and Adietya, B.A. (2019) ‘Pengaruh Posisi Pengelasan dan Bentuk Kampuh Terhadap Kekuatan Tarik dan Mikrografi Sambungan Las Metal Inert Gas (MIG) Pada Aluminium 6061 Sebagai Bahan Material Kapal’, Jurnal Teknik Perkapalan, 7(4), pp. 303–312.

Syinta, R.A., Aprizal, A. and Suripto, H. (2021) ‘Analisis Dan Pembuatan Chassis Tipe Ladder Frame Mobil Kmhe Urban Concept Menggunakan Metode Simulasi Dan Pahl And Beitz’, ENOTEK : Jurnal Energi dan Inovasi Teknologi, 1(01), pp. 14–18.

Toteles, A. and Alhaffis, F. (2021) ‘Analisis Material Kontruksi Chasis Mobil Listrik Laksamana V2 Menggunakan Software Autodesk Inventor’, Machine : Jurnal Teknik Mesin, 7(1), pp. 30–37.

Weriono, W. and Siregar, A.M. (2023) ‘Sistem Orientasi Tegangan Pada Chasis Aisi 4130 Gokart Phev Platform Baterai–Solar Panel’, Jurnal Rekayasa Material, Manufaktur dan Energi, 6(1), pp. 48–53.