Finite Element Analysis of Aluminum Based R22 Car Wheel Design Modification

DOI:

https://doi.org/10.35814/asiimetrik.v6i1.5077Keywords:

velg, von misses stress, equivalent strain, safety factor, displacementAbstract

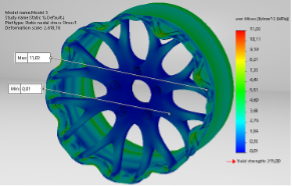

The wheels are one of the main parts of the vehicle. To make car wheels, manufacturers must complete several stages. Especially in the design of the wheels. This study aims to determine the comparative value of three different types of wheels with the same material using aluminum type 6061-T6 (SS). We will test the three-wheel models, namely model 1, model 2, and model 3, with a force of 3000 N and a pressure of 800 N to compare their performance. This test uses Solidworks 2019 software with the finite electronic analysis (FEA) method. The results obtained are the value of Von Misses stress, resulting displacement, equivalent strain and its deformation, and factor of safety. The dimensions of the wheels are 22 inches. The results of the best Model 3 alloy wheel research indicate that the design process is easier. These wheels have a Von Misses stress value of 11.02 MPa with a resulting displacement value of 0.021 mm, an equivalent strain of 0.000096, a safety factor of 25, and a deformation value of 1. Based on these results, model 3 alloy wheels are safe.

Downloads

References

Ali, H.A., Sawadi, A.S. and Tilefih, R.J. (2021) ‘Design and Analysis of Wheel Rims with Various Materials’, Journal of Mechanical Engineering Research and Developments, 44(11), pp. 96–107.

Bagherzadeh, F., Murugesan, S. and Deka, P. (2020) ‘Material Comparison of Dynamic Cornering Fatigue Test (Iso3006) for Automotive Wheel Rim’, International Journal of Engineering & Technology, 9(4), pp. 881–886.

Chai, W. et al. (2019) ‘Finite Element Analysis of The Residual Stress of Automotive Wheel Made of Long Glass Fiber-Reinforced Thermoplastic Composite’, Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 233(10), pp. 3592–3602.

HandWiki, H. (2023) 6061 Aluminium Alloy, Scholarly Community Encyclopedia. Available at: https://encyclopedia.pub/entry/35635#:~:text=6061%20Aluminium%20Alloy%20%7C%20Encyclopedia%20MDPI&text=6061%20(Unified%20Numbering%20System%20(UNS,it%20was%20developed%20in%201935. (Accessed: 3 March 2023).

Jadhav, M.V. and Mali, C.V. (2021) ‘Design of Wheel Rim by Using Design of Experiments’, International Journal of Advance Research, Ideas and Innovations in Technology, 7(4), pp. 890–896.

Jiang, X. et al. (2018) ‘Lightweight Design and Analysis of Automobile Wheel Based on Bending and Radial Loads’, in IOP Conference Series: Materials Science and Engineering. 2018 International Conference on Material Strength and Applied Mechanics, Japan: Kyushu Institute of Technology, p. 012048.

Naufal, H. (2019) ‘Studi Numerik Pengaruh Variasi Jumlah dan Ketebalan Spoke pada Velg Paduan Aluminium untuk Mobil MPV’, Jurnal Teknik Mesin, 8(1), pp. 39–47.

Prasetiyo, A.B. et al. (2022) ‘Analisis Frekuensi Natural Velg Ring 16 Menggunakan Finite Element Method’, in Prosiding Nasional Rekayasa Teknologi Industri dan Informasi XVII Tahun 2022 (ReTII). Seminar Nasional ReTII ke 17, Yogyakarta: Institut Teknologi Nasional Yogyakarta, pp. 354–359.

Pris, F.R., Suyitno, B.M. and Suhadi, A. (2019) ‘Analisis Kekuatan Velg Aluminium Alloy 17 Inc dari Berbagai Desain Menggunakan Metode Finite Element Analysis (FEA)’, Teknobiz : Jurnal Ilmiah Program Studi Magister Teknik Mesin, 9(2), pp. 33–39.

Rizki, M.Z.R.M., Anwar, C. and Heryadi, Y. (2021) ‘Analisis Kekuatan Velg Casting Wheel Sepeda Motor Berdasarkan Beban Penumpang dan Kondisi Jalanan Berlubang’, Jurnal Teknologika, 11(2), pp. 44–56.

Sumiyanto, S. and Abdunnaser, A. (2018) ‘Analisis Kekuatan Velg Alumunium Model D30D pada Perusahaan “A”’, Bina Teknika, 14(2), pp. 225–235.

Trimulya, C.T., Cholis, N. and Wahyuni, F. (2020) ‘Analisis Produk Pelek Motor Tipe Cast Wheel Berbahan Paduan Alumunium’, Bina Teknika, 16(2), pp. 79–84.

Wang, D., Zhang, S. and Xu, W. (2019) ‘Multi-Objective Optimization Design of Wheel Based on The Performance of 13° and 90° Impact Tests’, International Journal of Crashworthiness, 24(3), pp. 336–361.

Wibawa, D., Akbar, A. and Pramesti, Y. (2021) ‘Analisis Rangka Jayabaya Prototype 2.0 Menggunakan Aluminium Tipe AA356’, Prosiding SEMNAS INOTEK (Seminar Nasional Inovasi Teknologi), 5(3), pp. 188–193.

Wiley, R. and Elsaleiby, A. (2011) ‘A Review of Wheel Impact Measurement Variation’, in Technology Digest. March 2011. USA: Transportation Technology Center, Inc., p. TD-11-007.

Zapata, A., González-Estrada, O.A. and Pertuz, A. (2018) ‘Damage Model for The Impact Test of An Automotive Aluminum Wheel’, Journal of Physics: Conference Series, 1126(1), p. 012002.