The Effect of Air Pressure and Nozzle Distance on the Quality of Water-Based Painting Using a Gravity-Feed Spray Gun

DOI:

https://doi.org/10.35814/asiimetrik.v6i1.5187Keywords:

glossiness, nozzle distance, layer thickness, air pressure, water basedAbstract

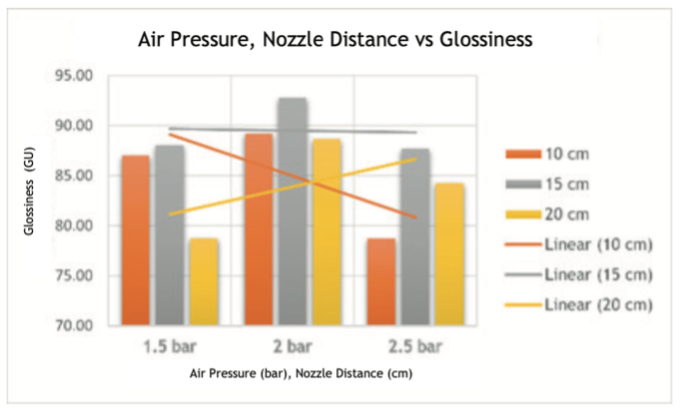

Environmental influences can cause corrosion or damage to materials, which is why paint coating is used to protect them. Some of the factors that affect the quality of the paint are technical, such as setting the air pressure and spray gun nozzle spacing. The experimental research aims to determine how air pressures of 1.5, 2, and 2.5 bar and nozzle spacings of 10–15–20 cm affect the gloss and thickness of the water-based paint layer. A gravity-feed spray gun was used for this purpose. The luster test method uses an AMTAST AMN60 glossmeter with the ASTM D523-08 standard, and the thickness test uses a coating thickness gauge with the ASTM E 376-96 standard. The air pressure and the distance of the spray gun nozzle affect the gloss and thickness of the paint layer. Parameter 2 bar/15 cm yielded the highest gloss of 92.77 GU, while parameter 2.5 bar/10 cm resulted in the highest coating thickness of 0.26 mm.

Downloads

References

Amookht, S. et al. (2013) ‘The effect of clear coat and basecoat interdiffusion on the appearance of automotive coating system’, Progress in Organic Coatings, 76(10), pp. 1325–1328.

Ardyanto, M.W. and Utama, F.Y. (2018) ‘Rekayasa Komposisi Mixing Solvent Dan Varnish Terhadap Kualitas Hasil Pengecatan Menggunakan Gloss Meter’, Jurnal Pendidikan Teknik Mesin (JPTM), 7(1), pp. 26–33.

Arif, Y.C., Eviningsih, R.P. and Widyanto, A.A. (2023) ‘Pengaturan Suhu Ruangan Oven Pengering Cat Panel Box menggunakan Logika Kontrol Fuzzy’, ELKOMIKA: Jurnal Teknik Energi Elektrik, Teknik Telekomunikasi, & Teknik Elektronika, 11(2), pp. 364–378.

ASTM, A. (1996) ‘ASTM E376-96: Standard Practice for Measuring Coating Thickness by Magnetic-Field or Eddy-Current (Electromagnetic) Test Methods’. ASTM International. Available at: https://webstore.ansi.org/standards/astm/astme37696 (Accessed: 3 January 2019).

ASTM, A. (2014) ‘ASTM D523-08: Standard Test Method for Specular Gloss’. ASTM International. Available at: https://www.astm.org/d0523-08.html (Accessed: 3 January 2020).

Bahtiar, F.Z. and Bahar, M.K. (2022) ‘Dampak Kadar Thinner Pu Terhadap Daya Kilap Pada Cat Dasar Lequer / Nitrocellulose (NC Semi Black Gloss)’, Journal of Automotive Technology Vocational Education, 3(1), pp. 7–13.

Dwiyati, S.T. (2015) ‘Pengaruh Kadar Hardener Terhadap Kualitas Produk Pengecatan Plastik’, Jurnal Konversi Energi dan Manufaktur, 2(2), pp. 65–72.

Dzikriansyah, M.F. (2017) Analisa Pengaruh Jarak Nozzle Dan Tekanan Udara Pada Pelapisan Dengan Metode Air Spray Terhadap Sifat Magnetik Komposit Barium Heksaferrit Polianilin. Thesis. Institut Teknologi Sepuluh Nopember.

Fajrah, N. and Perdana, Y.` (2019) ‘Analisis Penentuan Kriteria Kualitas Layanan Pengecatan Mobil’, Jurnal Sistem Teknik Industri, 21(2), pp. 70–81.

Harahap, J. (2018) ‘Efek Uraian Komposisi Cat Dan Jarak Penyemprotan Cat Pada Material H-Beam’, Teknobiz : Jurnal Ilmiah Program Studi Magister Teknik Mesin, 8(1), pp. 11–16.

Haryanto, E. and Ichtiarto, B.P. (2019) ‘Analisa Penurunan Cacat (Defect) Cat Bintik Debu Dengan Metodologi Six Sigma pada Proses Painting Produk Fuel Tank di PT. SSO Tangerang’, Jurnal Penelitian dan Aplikasi Sistem & Teknik Industri (PASTI), 13(3), pp. 326–337.

Hermawan, P. and Juhana, S. (2020) ‘Studi Surface Coating Dan Karakter Fisis Lapis Tipis Nano Partikel TiO2 Pada Kulit Finish’, Berkala Penelitian Teknologi Kulit, Sepatu, dan Produk Kulit, 19(1), pp. 15–28.

Hutama, T.S., Darsin, M. and Mulyadi, S. (2019) ‘Optimasi Variasi Diameter Nozzle, Tekanan Udara, Dan Suhu Pengeringan Pada Pelapisan Baja ST37 Menggunakan Metode Response Surface’, Simetris: Jurnal Teknik Mesin, Elektro dan Ilmu Komputer, 10(2), pp. 687–694.

Kaur, H. and Aul, G.D. (2014) ‘A Review Based on Effects of Change in Thickness and Number of Layers on Microwave Absorbing Materials’, International Journal of Science and Research (IJSR), 3(5), pp. 1141–1145.

Khan, M.A. and Hadromi, H. (2020) ‘Pengaruh Inhibitor Natrium Kromat Terhadap Laju Korosi Pada Komponen Radiator Sistem Pendingin Mobil’, Automotive Science and Education Journal, 9(1), pp. 18–24.

Khasanov, I., Rassokha, V. and Kabanova, O. (2019) ‘The study on the factors influencing the quality of paint and varnish coating when repairing the car body’, in IOP Conference Series: Materials Science and Engineering. International Conference on Innovations in Automotive and Aerospace Engineering, Russia: IOP Science, p. 012073.

Kristanto, Y., Rubiono, G. and Mujianto, H. (2017) ‘Pengaruh Diameter Nossel Spraygun Terhadap Efesiensi Pengecatan’, V-MAC (Virtual of Mechanical Engineering Article), 2(1), pp. 5–8.

Mulyanto, T., Supriyono and Arta, S.P. (2020) ‘Pengaruh Perlakuan Awal Terhadap Daya Rekat Dan Kekuatan Lapisan Pada Proses Pengecatan Serbuk’, Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa dan Inovasi, 2(1), pp. 25–32.

Rasyid, A.H.A., Santoso, D.I. and Utama, F.Y. (2017) ‘Pemilihan Parameter Pengecatan Untuk Mendapatkan Ketebalan Lapisan Cat Yang Tepat Untuk Permukaan Tidak Merata’, Otopro, 12(2), pp. 82–87.

Salim, S. (2019) ‘Pencegahan Korosi Kapal Dengan Metode Pengecatan’, Majalah Ilmiah Bahari Jogja, 17(2), pp. 93–99.

Sopiyan, S., Iqbal, M. and Susetyo, F.B. (2022) ‘Efek Variasi Campuran Solvent-Varnish dan Suhu Pengeringan terhadap Karakteristik Pelapis’, Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa dan Inovasi, 4(1), pp. 35–42.

Sriyana, H.Y. and Sudrajat, R.W. (2020) ‘Karakteristik Cat Clear Dari Limbah Ampas Aren’, Jurnal Inovasi Teknik Kimia, 5(1), pp. 28–31.

Streitberger, H.-J. and Dössel, K.-F. (2008) Automotive Paints and Coatings. Wiley‐VCH Verlag GmbH & Co. KGaA [Print].

Tyagita, D.A., Pratama, A.W. and Aprianto, D.B. (2019) ‘Variasi Kadar Tiner Dan Temperatur Pengeringan Terhadap Kualitas Hasil Pengecatan Bodi Kendaraan Berbahan ABS’, J-Proteksion: Jurnal Kajian Ilmiah dan Teknologi Teknik Mesin, 4(1), pp. 11–15.

Wijaya, Y.S.R. and Anwar, S. (2014) ‘Pengaruh Jarak Penyemprotan Spray Gun Terhadap Keoptimalan Hasil Pengecatan’, Jurnal Teknik Mesin Unesa, 2(3), pp. 88–95.

Wirojanupatump, S., Jiansirisomboon, S. and Sopadang, A. (2006) ‘Effect of Spray Parameters on Stainless Steel Arc Sprayed Coating’, Materials Science, Engineering, 03, pp. 1–3.

Yulliyanti, W., Susanty, D. and Wahyono, W. (2016) ‘Perbandingan Laju Korosi Pada Material Steel Plate Cold Coil (SPCC) Yang Dilapisi Cat Dengan Resin Yang Berbeda’, Jurnal Sains Natural, 6(1), pp. 16–20.