Geometry Characterization of Products Results in the Finishing Process Using Centerless Belt Grinding Machine

DOI:

https://doi.org/10.35814/asiimetrik.v6i1.5554Keywords:

centerless belt grinding, cylindrical, roundness, surface roughnessAbstract

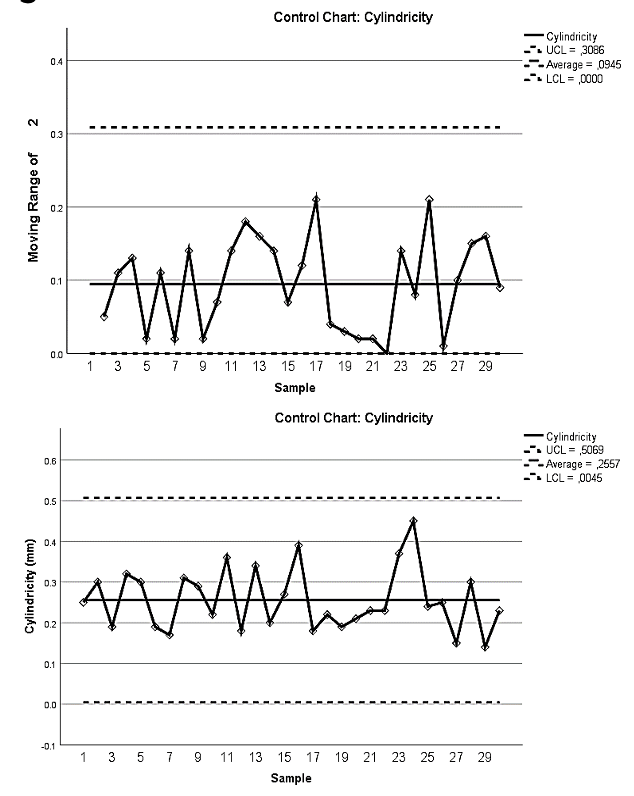

The centerless belt grinding machine that was previously designed at the Department of Mechanical Engineering at Universitas Trisakti can be used for finishing machining products. However, it is not yet known how the machine will perform on the geometric characteristics of the product as a result of the finishing process with a centerless belt grinding machine. The geometric characteristics here are the results of measurements in cylindricality, roundness, and surface roughness. This research aims to determine the machine's performance and whether there are significant differences in the centerless belt grinding finishing process. Control chart analysis is used to determine the consistency of engine performance, and a comparison of the feed speed is used to determine engine performance. Next, data processing was carried out using the paired sample t-test statistical test to determine whether there were significant differences between the turning and milling processes. The consistency test results indicated good performance achieved at a maximum speed of 25.47 mm/minute (angle 12°) for cylindrical, roundness, and surface roughness measurements. The statistical test results of the paired t-test between the turning and grinding processes showed significant differences, as indicated by the P-value (0.00) < ∝ (0.05) on cylindricality, roundness, and surface roughness.

Downloads

References

Abolghasem, S. and Mancilla-Cubides, N. (2022) ‘Optimization of Machining Parameters for Product Quality and Productivity in Turning Process of Aluminum’, Ingeniería Y Universidad: Engineering For Development, 26, pp. 1–27.

Alekseeva, I.A., Perelygina, O.V. and Kolyshkina, E.D. (2018) ‘Estimation of Consistency of Production of the Pertussis Component of DTP Vaccine in Terms of Immunogenic Activity and Specific Safety Using Shewhart Charts’, Biological Products. Prevention, Diagnosis, Treatment, 18(4), pp. 243–248.

Ariyanto, Husman and Dharta, Y. (2017) ‘Analisa Kinerja Bubut Doall LT13 Ditinjau dari Penyimpangan Ketelitian Geometri Mesin dan Kebulatan Benda Kerja’, in Prosiding Sentrinov (Seminar Nasional Terapan Riset Inovatif). Seminar Nasional Terapan Riset Inovatif (Sentrinov), Malang: Politeknik Negeri Malang, pp. TM95–TM106.

Aziz, A. and Mutaqin, M. (2023) ‘Pengaruh Variasi Media Pendingin Terhadap Sifat Mekanik Dan Struktur Mikro Pada Baja S45C’, Perwira Journal of Science & Engineering, 3(2), pp. 48–53.

Budiana, B. et al. (2020) ‘Analisis Kekasaran Permukaan Besi ASTM36 dengan menggunakan Surftest dan Image –J’, Journal of Applied Electrical Engineering, 4(2), pp. 49–54.

David, J., Mufarrih, A. and Istiqlaliyah, H. (2018) ‘Analisa Pengaruh Depth of Cut Dan Feeding Terhadap Kebulatan Hasil Pembubutan Silindris’, in Prosiding SEMNAS INOTEK (Seminar Nasional Inovasi Teknologi). Seminar Nasional Inovasi Teknologi (SEMNAS INOTEK), Kediri: Fakultas Teknik, Universitas Teknologi PGRI Kediri, pp. 275–280.

Erameh, A.A. et al. (2016) ‘Process Capability Analysis of a Centre Lathe Turning Process’, Engineering, 8(3), pp. 79–85.

Faraz, A., Saniga, E. and Montgomery, D. (2019) ‘Percentile-based control chart design with an application to Shewhart X̅ and S2 control charts’, Quality and Reliability Engineering International, 35(1), pp. 116–126.

Hamdi, E., Arief, D.S. and Prayitno, A. (2015) ‘Pengujian Kebulatan Hasil Pembuatan Poros Aluminium Menggunakan Emco T.U CNC - 2A Smkn 2 Pekanbaru Dengan Roundness Tester Machine’, Jurnal Online Mahasiswa (JOM) Bidang Teknik dan Sains, 2(2), pp. 1–8.

Jiang, G. et al. (2022) ‘Study of Surface Integrity of Titanium Alloy (TC4) by Belt Grinding to Achieve the Same Surface Roughness Range’, Micromachines, 13(11), pp. 1–22.

Leonesio, M., Bianchi, G. and Safarzadeh, H. (2019) ‘Stability Analysis of Centerless Grinding with Loss of Contact Nonlinearity’, in EPJ Web of Conferences. IV International Conference “Modeling of Nonlinear Processes and Systems” (MNPS-2019), Moscow, Russia: EPJ Web of Conferences, p. 05007.

Malindzakova, M., Čulková, K. and Trpčevská, J. (2023) ‘Shewhart Control Charts Implementation for Quality and Production Management’, Processes, 11(4), p. 1246.

Mamuka, R.A., Zuldesmi and Maukar, D.D. (2022) ‘Perancangan Mesin Amplas Dudukan Belt Dengan Menggunakan Motor Penggerak Listrik 125 Watt’, GEARBOX: Jurnal Pendidikan Teknik Mesin, 3(2), pp. 60–68.

Montolalu, C. and Langi, Y. (2018) ‘Pengaruh Pelatihan Dasar Komputer dan Teknologi Informasi bagi Guru-Guru dengan Uji-T Berpasangan (Paired Sample T-Test)’, d’Cartesian, 7(1), pp. 44–46.

Pandiyan, V. et al. (2020) ‘Modelling of Material Removal in Abrasive Belt Grinding Process: A Regression Approach’, Symmetry, 12(1), p. 99.

Ranger, J. et al. (2023) ‘A Multidimensional Partially Compensatory Response Time Model on Basis of the Log-Normal Distribution’, Journal of Educational and Behavioral Statistics, 0(0), p. 10769986231184153.

Rofarsyam, R. (2018) ‘Pembuatan mesin Amplas Sistem Sabuk Penggerak Motor Listrik’, Jurnal Rekayasa Mesin, 13(3), pp. 73–78.

Setiawan, I.H., Pramono, G.E. and Waluyo, R. (2023) ‘Rancang Bangun Mesin Belt Sander’, ALMIKANIKA, 5(2), pp. 46–55.