The Effect of Rotation Speed on the Quality of Friction Welding Joints in Aluminum and Copper

DOI:

https://doi.org/10.35814/asiimetrik.v6i2.5773Keywords:

friction welding, aluminum, copper, tensile test, microstructureAbstract

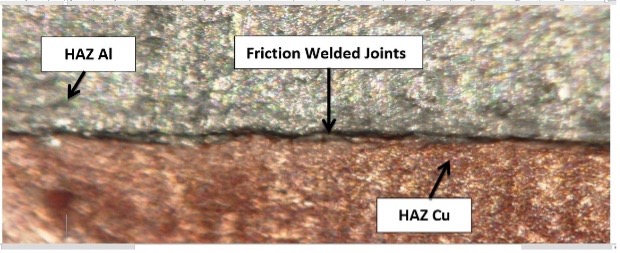

Welding of two different materials has high difficulty. It will cause porosity and hot cracks. To improve this, a friction welding (FRW) process has been developed to weld materials in a molten state. In this process, the material will be clamped so as not to be thrown, one other material will be rotated and brought together with the other clamped material and the pressure that causes the two sides of the material to meet. The purpose of this study is to determine the strength of welded joints of various materials through tensile testing and microstructure testing in friction welding (FRW) welding. This study used 6061 aluminium and ASTM B187 copper for welding. The cylinder had a diameter of 16 millimetres and a length of 70 millimetres, and the spindle rotational speeds were 1200 rpm, 1400 rpm and 1800 rpm. Welding results were assessed by measuring the strength of weld joints between different types of materials. Test results on welding with different spindle rotational speeds showed that friction welding with 1800 rpm was stronger with a maximum tensile strength of 2762.8 N and a tensile strength of 13.7N/mm2 when compared to 1200 rpm and 1400 rpm. In testing the microstructure of different types of materials, it can be seen that the mixture of the two metals at a rotational speed of 1800 rpm is more melting, so that the unification of the joining of the two materials is better when compared to the rotational speed of 1200 rpm and 1400 rpm.

Downloads

References

Barekatain, H., Kazeminezhad, M. and Kokabi, A.H. (2014) ‘Microstructure and Mechanical Properties in Dissimilar Butt Friction Stir Welding of Severely Plastic Deformed Aluminum AA 1050 and Commercially Pure Copper Sheets’, Journal of Materials Science & Technology, 30(8), pp. 826–834.

Darmulia (2016) ‘Pengaruh Variasi Putaran Motor terhadap Kekuatan Sambungan Las Friction Welding pada Baja ST. 60’, ILTEK : Jurnal Teknologi, 11(1), pp. 1567–1572.

Dzulfikar, M., Purwanto, H. and Munif, M.A. (2020) ‘Pengaruh Tekanan terhadap Sifat Mekanik dan Mikrostruktur pada Sambungan Las Gesek Aluminium AA1100’, in Prosiding Seminar Nasional TEKNOKA ke-5, 2020. Seminar Nasional TEKNOKA ke - 5, Jakarta, Indonesia: FT-UHAMKA, pp. 326–331.

Firmansyah, Y. (2021) ‘Analisis Kekuatan Tarik Sambungan Aluminium (Al) dan Tembaga Cu) Pada Pengelasan Gesek (Friction Welding) Dengan Variasi Waktu Gesek dan Tempa’, ROTASI, 23(3), pp. 9–15.

Gotawala, N. and Shrivastava, A. (2020) ‘Analysis Of Material Distribution In Dissimilar Friction Stir Welded Joints Of Al 1050 And Copper’, Journal of Manufacturing Processes, 57, pp. 725–736.

Huang, Y. et al. (2018) ‘Friction Stir Welding/Processing Of Polymers And Polymer Matrix Composites’, Composites Part A: Applied Science and Manufacturing, 105, pp. 235–257.

Husodo, N. (2011) ‘Peningkatan Peran Teknologi Friction Welding Dalam Memproduksi As Sepeda Motor Produk Industri Kecil’, in Prosiding Seminas Competitive Advantage. Seminar Nasional Competitive Advantage I, Jombang, Indonesia: Lembaga Pengembangan & Penelitian Unipdu, pp. 1–6.

Husodo, N. et al. (2013) ‘Penerapan Teknologi Las Gesek (Friction Welding) Dalam Rangka Penyambungan Dua Buah Logam Baja Karbon St41 Pada Produk Back Spring Pin’, J. Energy dan Manufaktur, 6(1), pp. 1–94.

Khaliq, U.A. et al. (2023) ‘A Review On Friction Stir Butt Welding Of Aluminum With Magnesium: A New Insight On Joining Mechanisms By Interfacial Enhancement’, Journal of Materials Research and Technology, 27, pp. 4595–4624.

Khojastehnezhad, V.M. and Pourasl, H.H. (2018) ‘Microstructural Characterization And Mechanical Properties Of Aluminum 6061-T6 Plates Welded With Copper Insert Plate (Al/Cu/Al) Using Friction Stir Welding’, Transactions of Nonferrous Metals Society of China, 28(3), pp. 415–426.

Liu, Q. et al. (2023) ‘Microstructure Evolution And Strengthening Mechanism Of Friction Stir Welded Joint Of 20 Mm-Thick AZ31 Magnesium Alloy’, Transactions of Nonferrous Metals Society of China, 33(11), pp. 3295–3308.

Manickam, S., Rajendran, C. and Balasubramanian, V. (2020) ‘Investigation Of FSSW Parameters On Shear Fracture Load Of AA6061 And Copper Alloy Joints’, Heliyon, 6(6), p. e04077.

McAndrew, A.R. et al. (2018) ‘A Literature Review Of Ti-6Al-4V Linear Friction Welding’, Progress in Materials Science, 92, pp. 225–257.

Pitchipoo, P. et al. (2021) ‘Friction Stir Welding Parameter Optimization Using Novel Multi Objective Dragonfly Algorithm’, International Journal of Lightweight Materials and Manufacture, 4(4), pp. 460–467.

Saefuloh, I. et al. (2023) ‘Karakteristik Sifat Mekanik Hasil Pengelasan Gesek Aluminium dengan Tembaga Menggunakan Variasi Kecepatan Putar dan Kekasaran Permukaan Kontak’, Malikussaleh Journal of Mechanical Science and Technology, 6(3), pp. 28–33.

Santoso, H. (2017) ‘Pengujian Struktur Mikro dan Mekanik pada Pipa Ketel Uap Sebelum dan Sesudah Pemakaian Selama 10 Tahun’, STRING (Satuan Tulisan Riset dan Inovasi Teknologi), 1(3), pp. 276–285.

Shi, H. et al. (2017) ‘Intermetallic Compounds in the Banded Structure and Their Effect on Mechanical Properties of Al/Mg Dissimilar Friction Stir Welding Joints’, Journal of Materials Science & Technology, 33(4), pp. 359–366.

Shrivas, S.P. et al. (2020) ‘Investigation Of TIG Welding Parameters To Improve Strength’, in Materials Today: Proceedings. 10th International Conference of Materials Processing and Characterization, USA: Gokaraju Rangaraju Institute of Engineering and Technology (10th International Conference of Materials Processing and Characterization), pp. 1897–1902.

Singh, P., Deepak, D. and Brar, G.S. (2023) ‘Investigations On The Effect Of Friction Crush Welding Parameters In Joining 6061 Aluminium Alloy To 304 Stainless Steel’, Journal of Mechanical Science and Technology, 37(4), pp. 1999–2008.

Tan, C.W. et al. (2013) ‘Microstructural Evolution And Mechanical Properties Of Dissimilar Al–Cu Joints Produced By Friction Stir Welding’, Materials & Design, 51, pp. 466–473.

Zhou, J., Wan, X. and Li, Y. (2015) ‘Advanced Aluminium Products and Manufacturing Technologies Applied on Vehicles Presented at the EuroCarBody Conference’, in Materials Today: Proceedings. Aluminium Two Thousand World Congress and International Conference on Extrusion and Benchmark ICEB 2015, Italy: DIN University of Bologna (Aluminium Two Thousand World Congress and International Conference on Extrusion and Benchmark ICEB 2015), pp. 5015–5022.