Effect of Heat Treatment Temperature on Hardness of Jaw Implant Produced from EDM Die-Sinking Process

DOI:

https://doi.org/10.35814/asiimetrik.v6i1.5784Keywords:

heat treatment, quenching, holding time, jaw implantAbstract

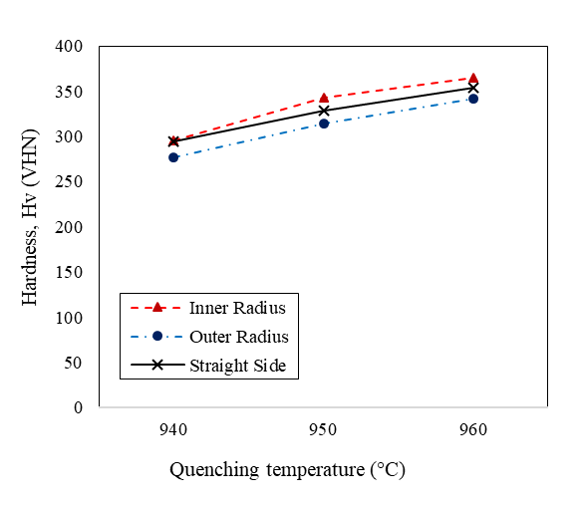

Hardness is the main problem in making jaw implants using the die-sinking EDM process. Heat treatment can increase the hardness of jaw implants resulting from the EDM process. This research investigates the influence of temperature during the heat treatment process on the hardness of jaw implants produced from the EDM process. Heat treatment uses a quenching process. The quenching temperatures used were 940, 950, and 960 ºC, while the holding time was 30 minutes. The aging temperature is 550 ºC. The research results show that the greater the quenching temperature, the greater the increase in hardness. The hardness of the white layer reaches 713 VHN when using a temperature of 960 ºC. Meanwhile, the hardness of the inner jaw implant reaches 354 VHN.

Downloads

References

Arab, A., Chen, P. and Guo, Y. (2019) ‘Effects of microstructure on the dynamic properties of TA15 titanium alloy’, Mechanics of Materials, 137, p. 103121.

Callister, W.D. and Wiley, J. (1980) ‘Materials Science’, Science, 208(4439), pp. 30–30.

Catherine, L.D.K. and Hamid, D.B.A. (2018) ‘The effect of heat treatment on the tensile strength and ductility of pure titanium grade 2’, IOP Conference Series: Materials Science and Engineering, 429(1), p. 012014.

Fopiano, P.J. and Hickey, C.F. (1973) ‘Comparison of the Heat Treatment Responses of Three Commercial Titanium Alloys’, Journal of Testing and Evaluation, 1(6), pp. 514–519.

Jian, S. et al. (2022) ‘Gradient microstructure and mechanical properties of Ti-6Al-4V titanium alloy fabricated by high-frequency induction quenching treatment’, Materials & Design, 222, p. 111031.

Kurniawan, Y. et al. (2019) ‘Effect of Preheating on Punch Force, Sheared Surface and Work Hardening in Cold Punching Process of Commercially Pure Titanium Sheet’, International Review of Mechanical Engineering (IREME), 13(9), pp. 504–512.

Kurniawan, Y. (2021) Proses Punching Lubang Lingkaran Dan Non-Symmetric Pada Pelat Commercially Pure Titanium (Cp-Ti) Sebagai Alternatif Proses Pembuatan Pelat Penyambung Tulang Rahang. Dissertation. Universitas Gadjah Mada.

Kurniawan, Y., Pangarsono, P.S., et al. (2022) ‘Effect of Pulse Current and Electrode Material in Producing of Microplate Implant by EDM Die-Sinking’, International Review of Mechanical Engineering (IREME), 16(10), pp. 564–572.

Kurniawan, Y., Tiyastianto, S.F., et al. (2022) ‘Pengaruh Material Elektroda Grafit dan Tembaga terhadap Material Removal Rate (MRR), Electrode Wear Rate (EWR) dan Kekerasan dalam Pembuatan Implan Rahang Menggunakan Dise-sinking EDM’, AME (Aplikasi Mekanika dan Energi): Jurnal Ilmiah Teknik Mesin, 8(2), pp. 104–109.

Kurniawan, Y. et al. (2023) ‘Dimensional Accuracy, Surface Roughness and Hardness Properties for Microplate Implants Manufacturing by EDM Die-Sinking Process’, International Journal of Automotive and Mechanical Engineering, 20(3), pp. 10606–10617.

Mpumlwana, D., Msomi, V. and Fourie, C.J.S. (2021) ‘Effect of Heat Treatment on the Mechanical Properties of a 3 mm Commercially Pure Titanium Plate (CP-Ti Grade 2)’, Journal of Engineering, 2021, p. e6646588.

Reda, R., Nofal, A. and Hussein, A.-H. (2013) ‘Effect of Single and Duplex Stage Heat Treatment on the Microstructure and Mechanical Properties of Cast Ti–6Al–4V Alloy’, Metallography, Microstructure, and Analysis, 2(6), pp. 388–393.

da Rocha, S.S. et al. (2006) ‘Vickers hardness of cast commercially pure titanium and Ti-6Al-4V alloy submitted to heat treatments’, Brazilian Dental Journal, 17(2), pp. 126–129.

Venkatesh, B.D., Chen, D.L. and Bhole, S.D. (2009) ‘Effect of heat treatment on mechanical properties of Ti–6Al–4V ELI alloy’, Materials Science and Engineering: A, 506(1), pp. 117–124.