Design of Rejection Subsystem for Abnormal Workpiece Condition Modular Production System at Distribution Station

DOI:

https://doi.org/10.35814/asiimetrik.v6i2.6144Keywords:

industrial automation, modular production system, rejection system, distribution stationAbstract

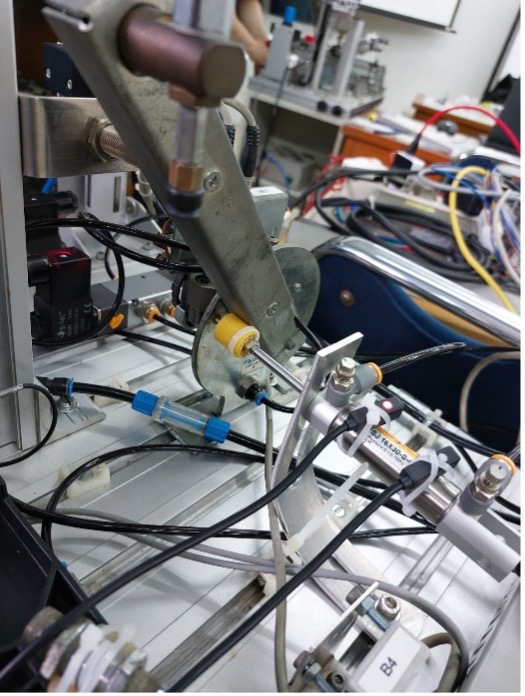

In the industrial era 4.0, the automation system technology used is growing rapidly. Automation systems in the industry are very useful, especially in reducing production time. One of the tools that can be used to simulate production in an industry is the Modular Production System (MPS). MPS itself consists of several stations to simulate the production process on a small scale. In a production system, of course, a system is needed that can detect abnormal workpiece conditions. This system will be driven by a Programmable Logic Controller (PLC). This system will be placed at the distribution station. The rejection system in MPS is needed because, in MPS there is still a manual process, namely in the process of inserting workpieces into the stack magazine. with this manual process, it is likely that workpieces with abnormal conditions will be processed by MPS. This condition is unlikely to be processed further to the pick and place station. Therefore, objects with abnormal conditions must be separated by this rejection system. There are 2 methods used to conduct this research, namely using the 5/3 valve and the positive stop method. Data collection from both methods is done by experiment. From the experimental results of the two methods, it can be seen that the best method used for this system is the positive stop method. This method is the most appropriate method because it can produce a very accurate swivel arm stop position. From the data obtained, using the 5/3 valve method with a pressure of 4 bar the swivel arm stop position ranges from 22.4 cm to reach more than 25.8 cm, and at a pressure of 5 bar the swivel arm height ranges from 25.8 cm to more. By using the positive stop method the swivel arm stops exactly at the specified swivel arm height because the swivel arm is held by the pneumatic cylinder.

Downloads

References

Aldean and Rafli, A.M. (2022) Otomasi Industri : Pengertian, Cara Menghitung, dan Keuntungannya, Mekari Jurnal. Available at: https://www.jurnal.id/id/blog/otomasi-industri-adalah-sbc/ (Accessed: 4 January 2023).

Aribowo, D. et al. (2021) ‘Sistem Perancangan Conveyor Menggunakan Sensor Proximity PR18-8DN Pada Wood Sanding Machine’, EDUSAINTEK: Jurnal Pendidikan, Sains dan Teknologi, 8(1), pp. 67–81.

Astuti, S.I., Arso, S.P. and Wigati, P.A. (2015) ‘Analisis Standar Pelayanan Minimal Pada Instalasi Rawat Jalan Di RSUD Kota Semarang’, Jurnal Kesehatan Masyarakat, 3(1), pp. 103–111.

Attaran, M. and Celik, B.G. (2023) ‘Digital Twin: Benefits, Use Cases, Challenges, And Opportunities’, Decision Analytics Journal, 6, p. 100165..

Badarudin, R. (2022) ‘Virtual Distributing Station Sebagai Sarana Media Pemrograman PLC’, Jurnal Edukasi Elektro, 6(2), pp. 75–84.

Bittner, K. and Spence, I. (2003) Use Case Modeling. Boston: Addison-Wesley Professional. [Print].

Bruns, W. and Schäfer, K. (2004) ‘Remote Control of Real and Virtual Welding Robots for Learning’, in IFAC Proceedings Volumes. 7th IFAC Symposium on Cost-Oriented Automation (COA 2004), Gatineau, Québec, Canada: IFAC Community (7th IFAC Symposium on Cost-Oriented Automation (COA 2004), Gatineau, Québec, Canada, 6-9 June 2004), pp. 215–219.

Fauziah, G.N. (2022) Rancangan Konveyor Pada Proses Perpindahan Material Pada Mesin Semi Otomasi Finger Joint Dari Pembuatan Produk Door Frame di PT. Interkayu Nusantara. Skripsi. Universitas Trisakti. Available at: http://103.49.68.23/usaktiana/index.php/home/detail/detail_koleksi/0/SKR/th_terbit/00000000000000107254/0# (Accessed: 19 July 2023).

FESTO (2007) ‘Learning Systems Modular Systems For Mechatronics Training’. FESTO. Available at: https://www.scribd.com/document/490765255/Modular-Learning-Systems-for-Mechatronics-Training (Accessed: 23 April 2027).

FESTO (2023) Semi-rotary drives DSR/DSRL, Catalog. Available at: https://www.festo.com/media/pim/160/D15000100122160.PDF (Accessed: 2 March 2023).

Hendri, A. et al. (2023) ‘Sistem Kerja Buka Tutup Pintu Secara Automatis Menggunakan Foto Sensor dan Sistem Manual Pneumatik’, Marine Science and Technology Journal, 3(2), pp. 39–44.

Kurniawan, A. et al. (2021) ‘Pelatihan Dasar Programmable Logic Controller (PLC) Berbasis Daring Menggunakan PLC Fiddle Untuk Guru SMK di Surabaya’, Sewagati, 5(3), pp. 278–285.

Lande, D. et al. (2018) ‘Automated System for Rejection of Poor Quality Material’, in IOSR Journal of Engineering (IOSRJEN). 7th National conference on Recent Developments in Mechanical Engineering RDME-2018, Pune, India: Department of Mechanical Engineering, College of Engineering, pp. 51–54.

Majedi, F. and Puspitasari, I. (2017) ‘Optimasi Daya dan Torsi pada Motor 4 Tak dengan Modifikasi Crankshaft dan Porting pada Cylinder Head’, JTT (Jurnal Teknologi Terpadu), 5(1), pp. 82–89.

Rachman, T. (2023) ‘Konsep Dasar Optimasi’. Universitas Esa Unggul. Available at: https://lms-paralel.esaunggul.ac.id/pluginfile.php?file=%2F174549%2Fmod_resource%2Fcontent%2F1%2F02_6623_TKT312_032019_pdf.pdf (Accessed: 7 February 2024).

Saputra, H. (2018) ‘Analisis Konsepsi Siswa Konsep Dinamika Gerak’, GRAVITASI: Jurnal Pendidikan Fisika dan Sains, 1(1), pp. 21–31.

Schilling, H. (2023) The translation dilemma - Intended use vs. intended purpose, seleon GmbH. Available at: https://www.seleon.com/en/the-translation-dilemma-intended-use-vs-intended-purpose/ (Accessed: 4 May 2024).

Siva, F.A., Irawan, A.P. and Utama, D.W. (2023) ‘Design and Optimization of Modular Production System Distribution and Pick & Place Station’, International Journal of Innovative Science and Research Technology (IJISRT), 8(7), pp. 3057–3065.

Tanojo, D. (2015) ‘Kontrol Modular Production System Berbasis PLC Siemens S7-300 Dengan Menggunakan HMI Touch Panel Damaris Tanojo’, CALYPTRA, 4(1), pp. 1–8.

Taufiq (2017) Modular Production System (MPS) Stasiun Distribusi Dengan Siemens S7300. 1st edn. Jakarta, Indonesia: Direktorat Pembinaan Sekolah Menengah Kejuruan Kementerian Pendidikan dan Kebudayaan. [Print].