Characteristics of Multi-tier Hybrid Dryer for Drying Corn Grains

DOI:

https://doi.org/10.35814/asiimetrik.v6i2.6370Keywords:

hybrid dryer, multi-tiered rack, solar collector, biomass furnace, corn grainsAbstract

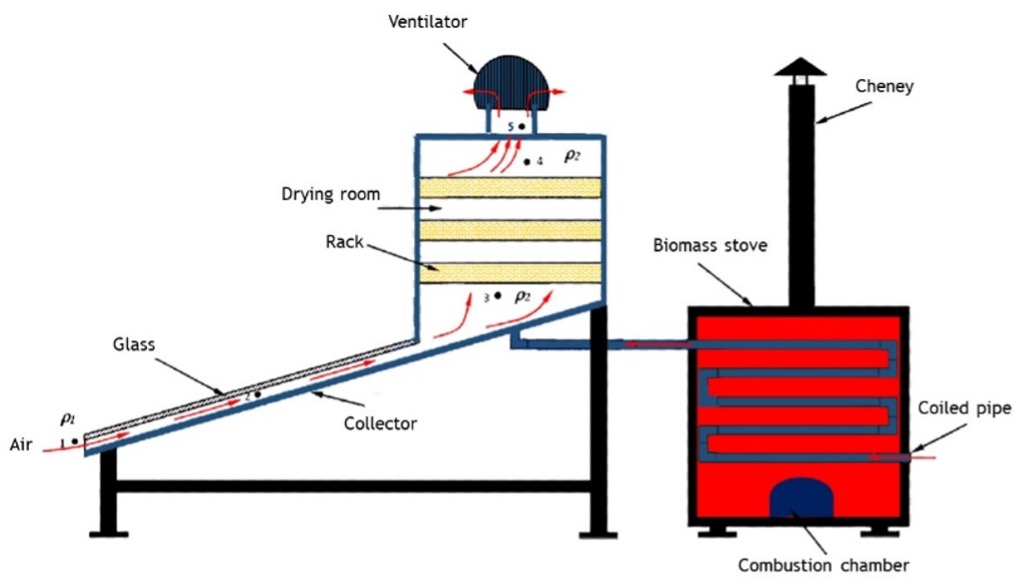

The type of drying device known as a hybrid dryer is a tool that harnesses solar energy and the heat generated by a biomass fuel-powered heat exchanger. This study was conducted to assess the performance of the hybrid dryer by analyzing the parameters of the device itself and the dried material. The research was carried out experimentally using a solar collector and a biomass furnace (as a heat exchanger) to heat the air. The solar collector used consists of 0.35 mm thick, black-painted zinc, coated with 5 mm thick glass, and installed at a 20-degree angle. The heat exchanger pipe used has a diameter of 1.25 inches and is made of galvanized pipe. The tested sample is corn seeds with an initial moisture content of about 24.6%. The experimental results show that in the drying process using a solar dryer, the initial moisture content of 24.8% was successfully reduced to 14% at 5.50 h (rack 1), 6.50 h (rack 2) and 7.00 h (rack 3) with a thermal efficiency of 24.25%. Meanwhile, in the hybrid drying process, the required time is approximately 5.00 h (rack 1), 5.50 h (rack 2) and 6.00 h (rack 3), with a efficiency of the drying equipment used is 21.048±5.690% (hybrid) and 22.706±6.437% (solar).

Downloads

References

Agrawal, S., Varshney, T. and Kumar, J. (2023) ‘Comparative Analysis of Hybrid Photovoltaic Thermal (PV/T) Solar Dryer’, Asian Journal of Water, Environment and Pollution, 20(1), pp. 57–66.

Arsenoaia, V.N. et al. (2023) ‘Drying Process Modeling and Quality Assessments Regarding an Innovative Seed Dryer’, Agriculture, 13(2), p. 328.

Banerjee, B.B. et al. (2022) ‘Role of Food Microwave Drying in Hybrid Drying Technology’, in A Comprehensive Review of the Versatile Dehydration Processes. London, UK: IntechOpen.

Behera, D.D., Mohanty, R.C. and Mohanty, A.M. (2023) ‘Thermal performance of a hybrid solar dryer through experimental and CFD investigation’, Journal of Food Process Engineering, 46(8), p. e14386.

Ciurzyńska, A. et al. (2022) ‘The Effect of Hybrid Drying Methods on the Quality of Dried Carrot’, Applied Sciences, 12(20), p. 10588.

Daksa, T.W. and Tolesa, G.N. (2023) ‘Review the Design of the Solar Dryer for the Dryer of Fruit and Vegetable Dryers’, International Journal of Food Engineering and Technology, 7(1), pp. 1–11.

Delahunt, C.B. et al. (2020) ‘Algorithms To Predict Moisture Content Of Grain Using Relative Humidity Time-Series’, in 2020 IEEE Global Humanitarian Technology Conference (GHTC). 2020 IEEE Global Humanitarian Technology Conference (GHTC), pp. 1–8.

Devi, T.B. et al. (2023) ‘Solar Dryer Using Evacuated Tube Solar Thermal Collector With Thermal Storage’, The Indian Journal of Agricultural Sciences, 93(2), pp. 233–236.

Hii, C.L. et al. (2021) ‘Hybrid Drying Of Food And Bioproducts: A Review’, Drying Technology, 39(11), pp. 1554–1576.

Jaganathan, G.K., Li, J. and Liu, B. (2022) ‘Low Constant Temperature Drying Can Be A Satisfactory Method To Determinethe Moisture Content Of Impermeable Seed Coated Species’, Southern Forests: a Journal of Forest Science, 84(4), pp. 325–327.

Jimoh, K.A. et al. (2023) ‘Recent Advances in the Drying Process of Grains’, Food Engineering Reviews, 15(3), pp. 548–576.

Kamarulzaman, A., Hasanuzzaman, M. and Rahim, N.A. (2021) ‘Global Advancement Of Solar Drying Technologies And Its Future Prospects: A Review’, Solar Energy, 221, pp. 559–582.

Kiburi, F.G. et al. (2023) ‘Exergetic Optimisation Of A Solar-Biomass Hybrid Greenhouse Dryer In Drying Banana Slices’, International Journal of Exergy, 41(1), pp. 41–59.

Li, B. et al. (2020) ‘Exergoeconomic Analysis of Corn Drying in a Novel Industrial Drying System’, Entropy, 22(6), p. 689.

Mabasso, G.A. et al. (2023) ‘The Effect Of Intermittent Drying With Variable Resting Times On Quality Parameters Of Corn Obtained After Storage’, LWT, 182, p. 114855..

Matin, A. et al. (2024) ‘Effect Of Conduction Drying On Nutrient And Fatty Acid Profiles: A Comparative Analysis Of Hazelnuts And Walnuts’, Frontiers in Sustainable Food Systems, 8, pp. 1–12.

Mykola, K. et al. (2021) ‘Influence of a New Energy-Saving Drying Method on the Quality of Corn Seeds’, American Journal of Agriculture and Forestry, 9(1), pp. 1–6.

Naigam, A.P.V. et al. (2021) ‘Design, Development And Performance Evaluation Of A Large-Scale Hybrid Solar Dryer’, in IOP Conference Series: Materials Science and Engineering. International Conference on Recent Innovations in Engineering and Technology (ICRIET 2020), Tamil Nadu, India: IOP Publishing, p. 012016.

Nwankwo, C.S. et al. (2023) ‘Recent Developments in the Hybridization of the Freeze-Drying Technique in Food Dehydration: A Review on Chemical and Sensory Qualities’, Foods, 12(18), p. 3437.

Olaoye, S.A. et al. (2023) ‘Developmental Trend of Hybrid Solar Dryer: A Comprehensive Review’, Journal of Engineering Research and Reports, 24(1), pp. 1–19.

Ponshanmugakumar, A. and Rajavel, R. (2022) ‘Enhancement of Heat Transfer in Solar Dehydrator for Agriculture Products’, in K. Mukherjee, R.K. Layek, and D. De (eds) Tailored Functional Materials. Singapore: Springer Nature, pp. 31–42.

Puchkov, E.M., Perov, G.A. and Solovyov, S.V. (2023) ‘Innovative Technology Of Drying Seeds Of Small-Seeded Crops’, Agrarian science, 9, pp. 161–165.

Putri, R.E., Pratama, W.E. and Ifmalinda, I. (2023) ‘Application of Capacitive Sensor for Measuring Grain Moisture Content Based on Internet of Things’, Jurnal Keteknikan Pertanian, 11(1), pp. 29–40.

Rizalman, M.K. et al. (2023) ‘A Review Of Solar Drying Technology For Agricultural Produce’, Indonesian Journal of Electrical Engineering and Computer Science, 30(3), pp. 1407–1419.

Sethy, S. et al. (2023) ‘Development of a Solar Tray Dryer’, International Journal for Research in Applied Science and Engineering Technology, 11(5), pp. 7576–7580.

Shammi, S. et al. (2022) ‘Temporal And Spatial Representation Of Temperature And Moisture In Drying Chamber And Its Impact On Vertical Vacuum Dehumidifying Rice Seed Dryer Performance’, Journal of Agriculture and Food Research, 10, p. 100424.

Sjechlad, D.Z. et al. (2022) ‘Analyzing The Homogeneity In The Reduction Of Water Content During The Drying Process Of Grains Using A Flatbed Dryer Machine Equipped With A Stirring Mechanization System’, INMATEH Agricultural Engineering, 68(3), pp. 201–210.

Suherman, S., Widuri, H., et al. (2020) ‘Energy Analysis of a Hybrid Solar Dryer for Drying Coffee Beans’, International Journal of Renewable Energy Development, 9(1), pp. 131–139.

Suherman, S., Hadiyanto, H., et al. (2020) ‘Hybrid Solar Dryer For Sugar-Palm Vermicelli Drying’, Journal of Food Process Engineering, 43(9), p. e13471.

Teymori-Omran, M. et al. (2023) ‘Enhancing Energy Efficiency and Retention of Bioactive Compounds in Apple Drying: Comparative Analysis of Combined Hot Air–Infrared Drying Strategies’, Applied Sciences, 13(13), p. 7612.

Wang, H. et al. (2023) ‘Modeling and Experimental Study on Drying Characteristics of Corn Particles with Hot Air in Downward Moving Bed’, Fluids, 8(2), p. 63.

Watson, A.G. et al. (2024) ‘A Simple Solar Crop Drying And Pasteurizing System Appropriate For Smallholder And Subsistence Farmers In Tropical And Subtropical Regions’, Drying Technology, 42(3), pp. 407–422.

Yuwana, Y., Silvia, E. and Sidebang, B. (2020) ‘Drying Air Temperature Profile Of Independent Hybrid Solar Dryer For Agricultural Products In Respect To Different Energy Supplies (A Research Note)’, IOP Conference Series: Earth and Environmental Science, 583(1), p. 012033.