Analysis of Vibration Characteristics in 17-Inch Aluminum Alloy Wheel Rims Using Finite Element Method

DOI:

https://doi.org/10.35814/asiimetrik.v6i2.6620Keywords:

wheel rim, natural frequency, mode shape, total deformation, ANSYSAbstract

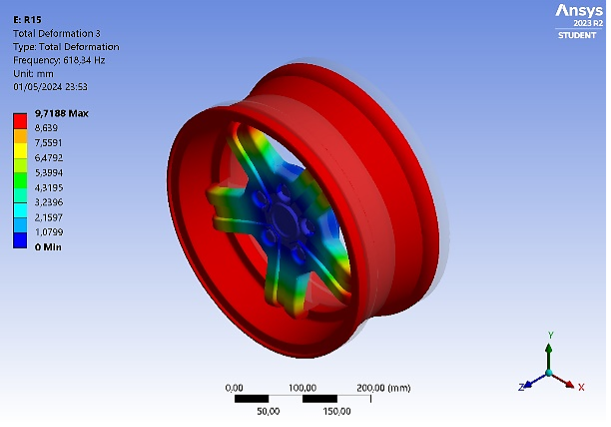

The wheel rim serves as a component designed to provide stability and necessary support for vehicle tires. The phenomenon of resonance occurring when the external vibration frequency approaches the natural frequency of the structure has the potential to increase vibration amplitude, which can lead to wheel rim damage. This study aims to investigate the shape patterns and natural frequencies of 17-inch aluminum alloy wheel rims, as well as to analyze the maximum total deformation that occurs. The finite element method is employed to simulate the vibration characteristic of 17-inch aluminum alloy wheel rims under various natural frequencies. Modifications to the wheel rim design are made by altering the spoke angle in variations of 5°, 10°, and 15°. The vibration characteristic data of the wheel rim was obtained through simulation using ANSYS software. The research findings indicate that the natural frequencies range from approximately 364.7 Hz to 723.21 Hz. Furthermore, the maximum total deformation values range from approximately 9.7 mm to 22.5 mm.

Downloads

References

Alfarisi, S., Ariyansah, R. and Mugisidi, D. (2024) ‘Finite Element Analysis of Aluminum Based R22 Car Wheel Design Modification’, Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa dan Inovasi, 6(1), pp. 1–10.

Ariyansah, R. (2019) ‘Modifikasi Desain Chasis Kendaraan Hybrid Pada Bus Scania K360Ib’, Teknobiz : Jurnal Ilmiah Program Studi Magister Teknik Mesin, 7(3), pp. 156–165.

Ashby, M.F. (2016) Materials and Sustainable Development. [Print].

Dani, P.A. et al. (2020) ‘Influence of Material and Spoke Pattern on the Performance of Automotive Wheels’, in Materials Today: Proceedings. 2nd International Conference on Materials Manufacturing and Modelling (ICMMM – 2019), Tamil Nadu, India: Vellore Institute of Technology (2nd International Conference on Materials Manufacturing and Modelling, ICMMM – 2019, VIT University, Vellore, 29th - 31st March 2019), pp. 1452–1459.

Gadwala, W.K. and Babu G, R. (2022) ‘Modeling And Analysis Of Car Wheel Rim For Weight Optimization To Use Additive Manufacturing Process’, in Materials Today: Proceedings. International Conference on Advances in Materials and Mechanical Engineering (ICAMME-2022), India (International Conference on Advances in Materials and Mechanical Engineering), pp. 336–345.

Guiju, Z. and Caiyuan, X. (2018) ‘Study On Lightweight Design Of Aluminium Alloy Wheels’, Australian Journal of Mechanical Engineering, 16(1), pp. 30–36.

Hermanto, Ariyansah, R. and Gamayel, A. (2021) ‘Analisis Kekuatan Struktur Rangka Pembangkit Listrik Sepeda Statis Menggunakan Perangkat Lunak Ansys Workbench’, Teknobiz : Jurnal Ilmiah Program Studi Magister Teknik Mesin, 11(1), pp. 20–25.

Li, S. et al. (2023) ‘Development And Applications Of Aluminum Alloys For Aerospace Industry’, Journal of Materials Research and Technology, 27, pp. 944–983.

Loganathan, K. and Subramani, S.K.V.S. (2023) ‘Design And Optimization Of Aluminium Alloy Wheel Rim In Automobile Industry’, Materials Today: Proceedings, Article in Press, pp. 1–6.

Naufal, H. (2019) ‘Studi Numerik Pengaruh Variasi Jumlah Dan Ketebalan Spoke Pada Velg Paduan Aluminium Untuk Mobil MPV’, Jurnal Teknik Mesin, 8(1), pp. 39–47.

Octavianus, G., Gamayel, A. and Ariyansah, R. (2022) ‘Simulasi Kekuatan Struktur Model Variasi Cakram Sepeda Motor Menggunakan Metode Elemen Hingga’, Journal Teknik Mesin, Elektro, Informatika, Kelautan dan Sains, 2(1), pp. 1–8.

Prasetiyo, A.B. et al. (2022) ‘Analisis Frekuensi Natural Velg Ring 16 Menggunakan Finite Element Method’, in Prosiding Rekayasa Teknologi Industri dan Informasi XVII Tahun 2022 (ReTII). Seminar Nasional Rekayasa Teknologi Industri dan Informasi XVII Tahun 2022 (ReTII), Yogyakarta, Indonesia: Institut Teknologi Nasional Yogyakarta, pp. 354–359.

Pris, F.R., Suyitno, B.M. and Suhadi, A. (2019) ‘Analisis Kekuatan Velg Aluminium Alloy 17 Inch Dari Berbagai Desain Menggunakan Metode Finite Element Analysis (FEA)’, Teknobiz : Jurnal Ilmiah Program Studi Magister Teknik Mesin, 9(2), pp. 33–39.

Rizqi, R.A., Rifky, R. and Ariyansah, R. (2023) ‘Analisis Dinamika Eksplisit Pada Pelek Ring 15 Dengan Metode Simulasi Uji Impak’, Teknobiz : Jurnal Ilmiah Program Studi Magister Teknik Mesin, 13(2), pp. 101–106.

Sivaraj, S., Nagendharan, S. and Mohanavel, V. (2020) ‘Experimental Investigation On Wheel Natural Frequency Performance Using Modal Analysis In Free And Loaded Condition’, in Materials Today: Proceedings. International Conference on Nanotechnology: Ideas, Innovation and Industries, Ramanathapuram, India: Syed Ammal Engineering College (International Conference on Nanotechnology: Ideas, Innovation and Industries), pp. 3234–3242.

Sofyan, D., Gamayel, A. and Zaenudin, M. (2023) ‘Simulasi Uji Impact Pada Desain Velg Berbahan ASTM A299 Diameter 15 Inch Dengan Standard Uji SAE J175’, Scientific Journal of Mechanical Engineering Kinematika, 8(1), pp. 85–93.

Somayaji, A. et al. (2022) ‘Studies On Modal Analysis Of Aluminium Based Carbon Fibre Reinforced Optimized Alloy Wheel Used In Automotive Sectors’, in Materials Today: Proceedings. International Conference on Smart and Sustainable Developments in Materials, Manufacturing and Energy Engineering, Karnataka, India: NMAM Institute of Technology (International Conference on Smart and Sustainable Developments in Materials, Manufacturing and Energy Engineering), pp. 274–277.

Stojanovic, B., Bukvic, М. and Epler, I. (2018) ‘Application of Aluminum and Aluminum Alloys in Engineering’, Applied Engineering Letters, 3(2), pp. 52–62.

Vijayakumar, R. et al. (2020) ‘Investigation on automobile wheel rim aluminium 6061 and 6066 Alloys using ANSYS WORKBENCH’, in Materials Today: Proceedings. International Conference on Nanotechnology: Ideas, Innovation and Industries 2020, India: Syed Ammal Engineering College (International Conference on Nanotechnology: Ideas, Innovation and Industries), pp. 3155–3159.

Win, H.H. and Oo, M.Z.T. (2019) ‘Modal Analysis Of Aluminum Alloy Five Spokes Wheel’, IRE Journals, 2(12), pp. 173–179.

Yulianto, F.A., Ariyansah, R. and Octavianus, G. (2023) ‘Analisis Modifikasi Desain pada Lokomotif CC-201 Tipe GE U18C dengan Metode Simulasi CFD’:, Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa dan Inovasi, 5(2), pp. 161–170.