Line Stop Time Reduction through Dandori Evaluation in Plastic Injection Process Production

DOI:

https://doi.org/10.35814/asiimetrik.v6i2.6624Keywords:

line stop, Dandori, 5W 1H analysis, work elementAbstract

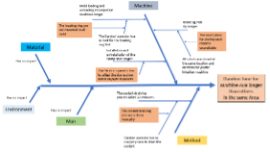

A quality product is a product that is efficiently produced. Line stops should be minimized to ensure efficient production. This study found a high line stop in the area of plastic injection machines caused by dandori. The line stops account for about 6% of the total production time 5.3% of them caused by dandori. Dandori is a line stop due to tools changing within a production process. This study aims to reduce the line stop by 30% and uses a fishbone analysis enhanced by the 5W+1H method for further analysis to reduce this problem. Enhancing the fishbone diagram with 5W+1H analysis produces a positive result. As a written calculation, this improvement gives a 28% line stop reduction, but it provides an average of 32.5% in actual operation. The improvement succeeded in reducing line stops due to dandori. The final achievement of 32% has passed the target of a 30% reduction and also provides an excellent cost-benefit ratio value of 20.9.

Downloads

References

Ajitomo, D.S. (2019) ‘Analisa Tingkat Kebisingan pada Mesin Strip Obat’, Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa dan Inovasi, 1(2), pp. 89–96.

Bilgili, B. and Özkul, E. (2019) ‘Industry 4.0-Tourism 4.0 And Human Factor: Voice Of Customer’, in European Proceedings of Social and Behavioural Sciences. New Challenges in Leadership and Technology Management, Prague, Czechia: Future Academy.

Chairudin, M.D., Ginting, N.B. and Fajri, H. (2020) ‘Information System for Selection of Production Line for Plastic Item Injection Machine Number A36 Using Priority Scheduling Method’, INTENSIF: Jurnal Ilmiah Penelitian dan Penerapan Teknologi Sistem Informasi, 4(2), pp. 232–246.

Denkena, B. et al. (2020) ‘Energy Efficient Machine Tools’, CIRP Annals, 69(2), pp. 646–667.

Ghosh, S. (2024) ‘Optimizing The Man-Machine Ratio To Make The Factory More Cost-Effective’, International Advanced Research Journal in Science, Engineering and Technology, 11(1), pp. 138–158.

Inayah, S.K., Wahyudin, W. and Herwanto, D. (2023) ‘Analisis Kualitas Produk Toolbox Menggunakan Metode Seven Tools di PT. KSKB’, Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa dan Inovasi, 5(2), pp. 263–272.

Kurnia, T.E. and Listanti, A.T. (2019) ‘Identifikasi Preferensi Konsumen Produk Kerupuk Jambu Biji Merah Menggunakan Metode QFD’, Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa dan Inovasi, 1(2), pp. 113–123.

Kurnia, T.E. and Sugiyanto (2021) ‘Analisis Peningkatan Efektivitas pada Perusahan Kargo dengan Metode Six Sigma DMAIC dan FMEA’, Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa dan Inovasi, 3(1), pp. 29–34.

Mullick, A. (2023) A Real Options Approach to Design for Quality Standards Considering Life Cycle of a Product. thesis. Toronto Metropolitan University.

Oliveira, M.M.D. et al. (2021) ‘Product Lifecycle Management and Sustainable Development in the Context of Industry 4.0: A Systematic Literature Review’, in Transdisciplinary Engineering for Resilience: Responding to System Disruptions. USA: IOS Press, pp. 213–222.

Pacana, A. and Siwiec, D. (2024) ‘Predicting Quality of Modified Product Attributes to Achieve Customer Satisfaction’, Designs, 8(2), p. 36.

Sari, E.M. and Darmawan, M.M. (2020) ‘Pengukuran Waktu Baku dan Analisis Beban Kerja pada Proses FIlling dan Packing Produk Lulur Mandi di PT. Gloria Origita Cosmetics’, Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa dan Inovasi, 2(1), pp. 51–61.

Sarkar, B., Omair, M. and Choi, S.-B. (2018) ‘A Multi-Objective Optimization of Energy, Economic, and Carbon Emission in a Production Model under Sustainable Supply Chain Management’, Applied Sciences, 8(10), p. 1744.

Voronkova, V., Punchenko, O. and Azhazha, M. (2020) ‘Globalization and Global Governance in the Fourth Industrial Revolution (Industry 4.0)’, Humanities Studies, 4(81), pp. 182–200.

Wójcicki, J. (2017) Energy Efficiency Of Machine Tools. Dissertation. Politecnico di Milano.

Xing, S. et al. (2021) ‘Optimization Of Milling Parameters Considering High Efficiency And Low Carbon Based On Gravity Search Algorithm’, Journal of Intelligent & Fuzzy Systems, 41(6), pp. 6303–6321.

Yin, R. et al. (2019) ‘A Cutting Parameter-Based Model For Cost And Carbon Emission Optimisation In A NC Turning Process’, International Journal of Computer Integrated Manufacturing, 32(10), pp. 919–935.

Zhao, G. et al. (2018) ‘Energy Consumption Characteristics and Influence on Surface Quality in Milling’, in Procedia CIRP. 4th CIRP Conference on Surface Integrity (CSI 2018), Tianjin, China: Elsevier Procedia (4th CIRP Conference on Surface Integrity (CSI 2018)), pp. 111–115