Optimization of Dehumidification Air Flow Distribution in Temulawak Tray Dryer with Computational Fluid Dynamics

DOI:

https://doi.org/10.35814/asiimetrik.v6i2.6664Keywords:

air distribution, tray dryer, CFDAbstract

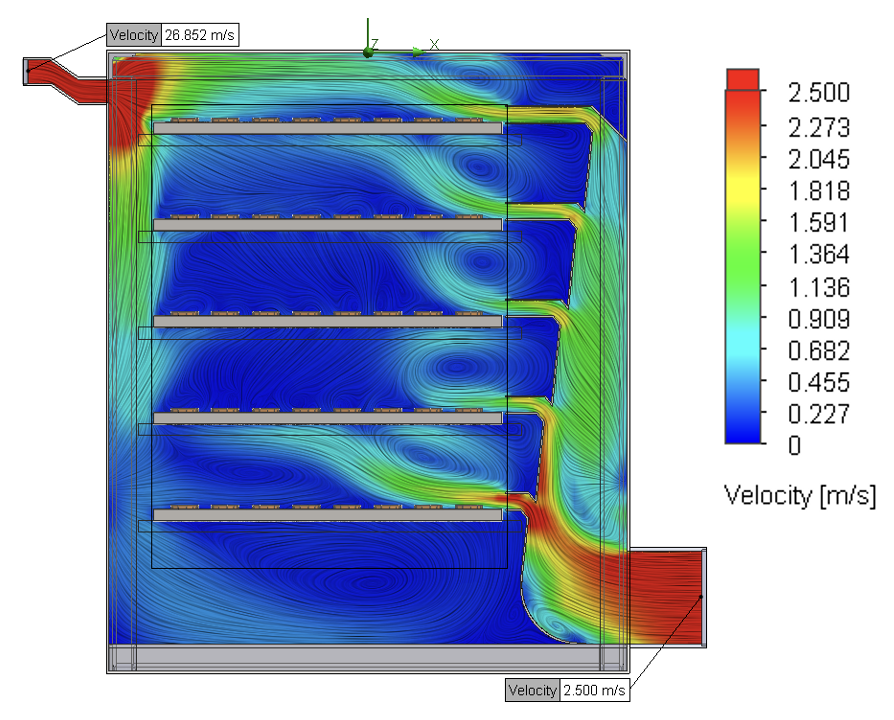

Temulawak (Curcuma xanthorrhiza Roxb.), a member of the Zingiberaceae family, has long been recognized as a medicinal plant with a moisture content approximately 80-90%. The high moisture content of temulawak renders it challenging to store for extended periods without drying. Temulawak is susceptible to heat damage due to the potential for thermal degradation of its internal components. Accordingly, it can be concluded that low-temperature and low-air-humidity drying conditions are required. Furthermore, one of the most suitable methods is the use of a dryer that incorporates a dehumidification process. The objective of this research is to develop a temulawak dryer design and simulation variations of the incoming velocity of air flow to obtain the most optimal drying chamber by incorporating a vertical airflow channel. A design and simulation for a temulawak dryer were created using the 2022 version of SolidWorks software (flow simulation modul). The design started from drawing two-dimension, then three-dimension, and determining boundary condition and meshing. A fluid temperature of 35.7°C and a relative humidity (RH) of 22% were used to model the drying process at varying airflow velocities of 1.5 m/s, 2 m/s, and 2.5 m/s. The drying chamber, with dimensions of 676 mm x 406 mm and height of 806 mm, was designed using the type AISI 304 and achieved the most optimal airflow distribution results at a velocity of 2.5 m/s, exhibiting a relatively higher fluid temperature than the other two airflow velocity variation.

Downloads

References

Abeyrathna, R.M.R.D., Ekanayake, E.M.A.C. and Amaratunga, K.S.P. (2020) ‘Industrial Robotic Arm for Chilli Milling Process’, International Journal of Innovative Technology and Exploring Engineering (IJITEE), 9(12), pp. 130–133.

Akhtar, M.U.S. et al. (2024) ‘Sustainable Humidity Control In The Built Environment: Recent Research And Technological Advancements In Thermal Driven Dehumidification Systems’, Energy and Buildings, 304, p. 113846.

Asadbeigi, Sh. et al. (2023) ‘Analyzing And Simulating Heat Transfer And Designing A Shell And Tube Heat Exchanger For The Pasteurization Process Of Tomato Paste: A CFD Study’, Heliyon, 9(11), p. e21593.

Biksono, D. et al. (2022) ‘Distribusi Suhu dan Kecepatan Aliran Udara dari Sistem Heat Pump Kompresi Uap untuk Ruang Pengering Tipe Drum Horizontal dengan Bantuan Computational Fluid Dynamics’, Jurnal Teknologi, 10(1), pp. 86–99.

Billad, R.F. et al. (2024) ‘Numerical Modelling of NACA 0015 Airfoil Under the Erosion Condition’, Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa dan Inovasi, 6(1), pp. 133–142.

Haryanto, A., Sutoyo, E. and Sutisna, S.P. (2019) ‘Studi Faktor Persebaran Suhu Dan Aliran Fluida Dalam Pengering Pakaian Menggunakan Metode Numerik Dan CFD’, AME (Aplikasi Mekanika dan Energi): Jurnal Ilmiah Teknik Mesin, 5(1), pp. 38–46.

Hidayati, B., Baharuddin and Wahyudi, R. (2020) ‘Air Moisture Analysis of Potato Dehumidification Process Using The Refrigeration System’, AUSTENIT, 12(1), pp. 1–5.

Liu, Q. et al. (2022) ‘Comparison Of Different Drying Techniques For Shiitake Mushroom (Lentinus Edodes): Changes In Volatile Compounds, Taste Properties, And Texture Qualities’, LWT, 164, p. 113651.

Pratiwi, D. and Wardaniati, I. (2019) ‘Pengaruh Variasi Perlakuan (Segar dan Simplisia) Rimpang Kunyit (Curcuma domestica) Terhadap Aktivitas Antioksidan dan Kadar Fenol Total’, Jurnal Farmasi Higea, 11(2), pp. 159–165.

Putra, A.S. and Kuncoro, H. (2021) ‘Pengaruh Kondisi Pengeringan Dengan Kelembaban Dan Suhu Rendah Terhadap Penyusutan Temulawak’, Jurnal Teknologi Pertanian Andalas, 25(1), pp. 81–89.

Putri, A.O. et al. (2021) ‘Rancang Bangun Alat Tipe Spray Dryer Untuk Proses Pengeringan Susu Bubuk Berbasis Jagung Manis (Zea Mays Saccharata)’, KINETIKA, 12(3), pp. 31–37.

Santoso, I. et al. (2023) ‘Peningkatan Nilai Tambah Simplisa Jahe Merah Subgrade Di Bumdesma Sari Bumi, Kecamatan Pule, Kabupaten Trenggalek’, Journal of Innovation and Applied Technology, 9(2), pp. 24–29.

Sihite, N.W. and Hutasoit, M.S. (2023) ‘Potensi Bahan Pangan Lokal Indonesia Sebagai Pangan Fungsional Dan Manfaatnya Bagi Kesehatan :Review’, JURNAL RISET GIZI, 11(2), pp. 133–138.

Sudirman et al. (2023) ‘Aplikasi Cooling Dehumidification pada Mesin Pengering untuk Mengeringkan Hasil Panen Tanaman Herbal’, Jurnal Rekayasa Mesin, 18(1), pp. 37–44.

Sukmawati, W. and Merina, M. (2019) ‘Pelatihan Pembuatan Minuman Herbal Instan Untuk Meningkatkan Ekonomi Warga’, JURNAL PENGABDIAN KEPADA MASYARAKAT, 25(4), pp. 210–215.

Sungkono and Ismarwanti, S. (2021) ‘Pengaruh Perlakuan Panas Terhadap Perilaku Tarik Dan Struktur Mikro Baja Tahan Karat Aisi 304 Pada Daerah Sensitisasi 600 – 700 °C’, Urania : Jurnal Ilmiah Daur Bahan Bakar Nuklir, 27(3), pp. 123–132.

Suryanantha, I.W., Yulianti, N.L. and Sulastri, N.N. (2022) ‘Optimasi Suhu Pengeringan dan Ketebalan Irisan pada Proses Pengeringan Temulawak (Curcuma Xanthorrhiza Roxb) dengan Response Surface Methodology (RSM)’, Jurnal BETA (Biosistem dan Teknik Pertanian), 10(2), pp. 259–268.