Erosive Wear Characteristics Analysis of High Chromium White Cast Iron using Finite Element Analysis (FEA)

DOI:

https://doi.org/10.35814/asiimetrik.v7i1.7476Keywords:

Erosion model, finite element analysis (FEA), high chromium white cast ironAbstract

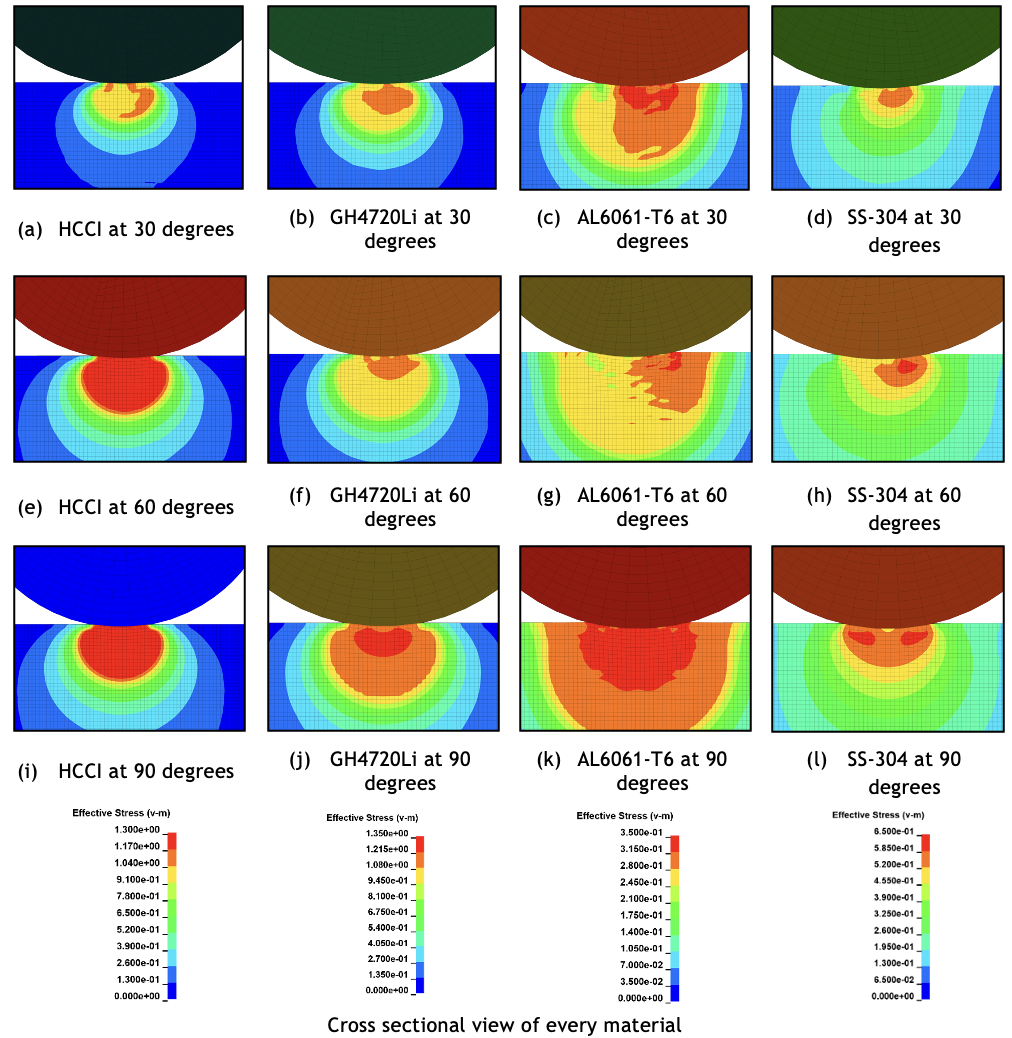

Erosive wear often occurs on heavy machinery operating under extreme conditions. This research utilizes the Finite Element Analysis (FEA) method with the Cowper-Symonds strain rate model to analyze the erosion behavior of high-Cr cast iron (HCCI) under different impact angles and compare it to other materials of different characteristics, such as 6061-T6 Aluminium, GH4720Li Superalloy, and Stainless Steel 304 Annealed. A single particle erosion model was made for this study. The erodent particle size used is 0.7 mm in diameter, with the target material measuring 1 x 1 x 0.5 mm. The particle velocity is kept constant at 25 m/s. Based on the simulation results, it can be known that HCCI performs the best at every impact angle. Moreover, from the model's cross-section, it's evident that the material's stress concentration aligns with the direction of movement of the erodent particle. Therefore, it can be concluded that these factors, along with others such as contact time, plastic strain, and surface deformation lead to variations in surface mechanics.

Downloads

References

Aziz, Kh.A., Shennawy, M.E. and Omar, A.A. (2017) ‘Microstructural Characteristics and Mechanical Properties of Heat Treated High-Cr White Cast Iron Alloys’, International Journal of Applied Engineering Research, 12(4), pp. 4675–4686.

Fernández, I. and Belzunce, F.J. (2008) ‘Wear And Oxidation Behaviour Of High-Chromium White Cast Irons’, Materials Characterization, 59(6), pp. 669–674. Available at: https://doi.org/10.1016/j.matchar.2007.05.021.

Finnie, I. (1960) ‘Erosion Of Surfaces By Solid Particles’, Wear, 3(2), pp. 87–103. Available at: https://doi.org/10.1016/0043-1648(60)90055-7.

Hernandez, C. et al. (2013) ‘A Computational Determination Of The Cowper–Symonds Parameters From A Single Taylor Test’, Applied Mathematical Modelling, 37(7), pp. 4698–4708. Available at: https://doi.org/10.1016/j.apm.2012.10.010.

Kusumoto, K. et al. (2024) ‘Effect Of Carbide Refinement On High Temperature Erosive Wear Behavior Of High Chromium White Cast Iron With Different Titanium And Carbon Additions’, Materials Today Communications, 39, p. 109276. Available at: https://doi.org/10.1016/j.mtcomm.2024.109276.

Ngqase, M. and Pan, X. (2020) ‘An Overview on Types of White Cast Irons and High Chromium White Cast Irons’, in Journal of Physics: Conference Series. International Conference on Multifunctional Materials (ICMM-2019), Hyderabad, India: IOP Publishing, p. 012023. Available at: https://doi.org/10.1088/1742-6596/1495/1/012023.

Pariente, I.F., Belzunce, F.J. and Riba, C.R. y J. (2008) ‘Mechanical Strength And Fracture Toughness Of High Chromium White Cast Irons’, Materials Science and Technology, 24(8), pp. 981–985. Available at: https://doi.org/10.1179/174328407X213161.

Patil, H. and Jeyakarthikeyan, P.V. (2018) ‘Mesh Convergence Study And Estimation Of Discretization Error Of Hub In Clutch Disc With Integration Of ANSYS’, in IOP Conference Series: Materials Science and Engineering. 2nd International conference on Advances in Mechanical Engineering (ICAME 2018), Kattankulathur, India: IOP Publishing, p. 012065. Available at: https://doi.org/10.1088/1757-899X/402/1/012065.

Prayogo, R.S. and Setyana, L.D. (2021) ‘The Improvement of Wear and Impact Resistance of High Chromium White Cast Iron for Crusher’, Journal of Material Processing and Characterization, 1(2), pp. 96–102. Available at: https://doi.org/10.22146/jmpc.68282.

Shimizu, K. et al. (2019) ‘Microstructural Evaluation And High-Temperature Erosion Characteristics Of High Chromium Cast Irons’, Wear, 426–427(Part A), pp. 420–427. Available at: https://doi.org/10.1016/j.wear.2019.01.043.

Touhami, R.C. et al. (2023) ‘Wear Behavior and Microstructure Changes of a High Chromium Cast Iron: The Combined Effect of Heat Treatment and Alloying Elements’, Metallography, Microstructure, and Analysis, 12(4), pp. 580–590. Available at: https://doi.org/10.1007/s13632-023-00976-w.

Xiao, L., Shimizu, K. and Kusumoto, K. (2017) ‘Impact Angle Dependence of Erosive Wear for Spheroidal Carbide Cast Iron’, Materials Transactions, 58(7), pp. 1032–1037. Available at: https://doi.org/10.2320/matertrans.F-M2017816.

Yaer, X. et al. (2019) ‘Surface Deformation Micromechanics Of Erosion Damage At Different Angles And Velocities For Aero-Engine Hot-End Components’, Wear, 426–427, pp. 527–538. Available at: https://doi.org/10.1016/j.wear.2018.12.054.

Zhang, J. and Liu, H. (2023) ‘Effect Of Solid Particles On Performance And Erosion Characteristics Of A High-Pressure Turbine’, Energy, 272, p. 127185. Available at: https://doi.org/10.1016/j.energy.2023.127185.

Zheng, C. et al. (2017) ‘Finite Element Analysis On The Dynamic Erosion Process Using Multiple-Particle Impact Model’, Powder Technology, 315, pp. 163–170. Available at: https://doi.org/10.1016/j.powtec.2017.04.016.