Inventory Management and Proactive Maintenance to Enhance Operational Efficiency in Excavators: Focus on Common Spare Parts Issues

DOI:

https://doi.org/10.35814/asiimetrik.v7i1.7770Keywords:

Min-max approach, spare parts management, damage prevention, proactive inspections, scheduled maintenanceAbstract

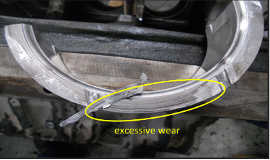

Effective inventory management and maintenance are critical for the operational efficiency of heavy equipment such as excavators. This study focuses on optimizing spare parts inventory for Cummins diesel engines using the min-max stock method. It aims to improve inventory control by categorizing spare parts into slow-moving, medium-moving, and fast-moving components and addressing maintenance issues that impact performance. The research utilized the min-max stock method to determine optimal inventory levels, ensuring spare parts availability while minimizing holding costs. Key maintenance issues in components such as track shoes, cam shafts, rear shafts, motor starters, and exhaust manifolds were identified through inspections. Advanced diagnostic tools, including vibration analyzers and thermal imaging, were used for proactive maintenance. The study identified critical wear and damage in components like track shoes, cam shafts, and exhaust manifolds, which could lead to equipment failure if not addressed. Implementing the min-max stock method helped reduce stockouts and overstocking, ensuring an optimal balance in inventory. The results demonstrate that integrating the min-max stock method with systematic maintenance practices significantly improves operational efficiency. The use of real-time diagnostic tools enabled early issue detection, reducing downtime and maintenance costs. This study emphasizes the importance of inventory optimization, regular inspections, and timely maintenance interventions for enhancing equipment reliability. Future research should explore predictive maintenance technologies to further refine inventory and maintenance strategies in the heavy equipment sector.

Downloads

References

Becerra, P., Mula, J. and Sanchis, R. (2022) ‘Sustainable Inventory Management in Supply Chains: Trends and Further Research’, Sustainability, 14(5), p. 2613. Available at: https://doi.org/10.3390/su14052613.

Enache, M.-A. et al. (2019) ‘Dynamic State of Starting for a High-Power Asynchronous Motor Used for Driving a Surface Mining Excavator’, in 2019 11th International Symposium on Advanced Topics in Electrical Engineering (ATEE). 11th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania: IEEE, pp. 1–6. Available at: https://doi.org/10.1109/ATEE.2019.8724954.

Endler, C. and Júnior, P.P.A. (2018) ‘Model of Identification and Management of Technological Innovations in Product Development: A Case Study in the Automotive Industry’, Engineering Management Research, 7(2), p. p30. Available at: https://doi.org/10.5539/emr.v7n2p30.

Fachrizal, M.F. and Suryo, S.H. (2018) ‘The Influence of Material Strengthon Excavator Track Shoe Using Abrasive Wear Testingwith Ogoshi High Speed Universal Wear Testing Method’, ARPN Journal of Engineering and Applied Sciences, 13(16), pp. 4648–4658.

Fatroni, H., Saragi, S. and Widyastuti, S. (2024) ‘Optimization of the Minmax Function as Inventory Management on Non-Prescription Products at Kimia Farma Pharmacy Balikpapan’, International Journal of Science and Society (IJSOC), 6(2), pp. 62–72. Available at: https://doi.org/10.54783/ijsoc.v6i2.1110.

Gocmez, T. and Deuster, U. (2009) An Integral Engineering Solution for Design of Exhaust Manifolds. SAE Technical Paper 2009-01–1229. Warrendale, PA: SAE Technical Paper. Available at: https://doi.org/10.4271/2009-01-1229.

Helu, M. et al. (2020) ‘Industry Review of Distributed Production in Discrete Manufacturing’, Journal of Manufacturing Science and Engineering, 142(110802), pp. 1–13. Available at: https://doi.org/10.1115/1.4046988.

Hematabadi, A.A. and Foroud, A.A. (2019) ‘Optimizing The Multi-Objective Bidding Strategy Using Min–Max Technique And Modified Water Wave Optimization Method’, Neural Computing and Applications, 31(9), pp. 5207–5225. Available at: https://doi.org/10.1007/s00521-018-3361-0.

Julius, A. (2024) ‘Inventory Management Strategy and its Impact on Production Efficiency: An Empirical Evidence of Mukwano Manufacturing Industries’, International Journal of Academic Pedagogical Research (IJAPR), 8(4), pp. 96–99.

Khangar, V.S. and Jaju, S.B. (2012) ‘A Review of Various Methodologies Used for Shaft Failure Analysis’, International Journal of Emerging Technology and Advanced Engineering, 2(6), pp. 50–54.

Liu, X., Xu, Z. and Zheng, M. (2024) ‘Optimal inventory decisions of infrequently needed spare parts for maintenance with inaccurate demand forecasts and limited storage space’, Journal of Physics: Conference Series, 2853(1), p. 012063. Available at: https://doi.org/10.1088/1742-6596/2853/1/012063.

Panigrahi, R.R. et al. (2019) ‘Advance Inventory Management Practices and Its Impact on Production Performance of Manufacturing Industry’, International Journal of Recent Technology and Engineering, 8(4), pp. 3875–3880. Available at: https://doi.org/10.35940/ijrte.D8266.118419.

Panigrahi, R.R., Shrivastava, A.K. and Kapur, P.K. (2024) ‘Impact of inventory management practices on the operational performances of SMEs: review and future research directions’, International Journal of System Assurance Engineering and Management, 15(5), pp. 1934–1955. Available at: https://doi.org/10.1007/s13198-023-02216-4.

Rusiński, E. et al. (2018) Surface Mining Machines: Problems of Maintenance and Modernization. Springer. [Print].

Salahudeen, L.A. and A, A.O. (2018) ‘Effect Of Inventory Management System On Operational Performance In Manufacturing Firms: Study Of May And Baker Manufacturing Industry Nig Ltd, Lagos’, IRE Journals, 2(5), pp. 156–171.

Shahi, S. et al. (2017) ‘Optimal production-inventory model for forest products industry supply chain under demand and supply uncertainty: Case study of a pulp mill in Ontario’, Cogent Business & Management. Edited by S. Liu, 4(1), p. 1370765. Available at: https://doi.org/10.1080/23311975.2017.1370765

Shukaili, S.M.S.A., Jamaluddin, Z. and Zulkifli, N. (2023) ‘The Impact of Strategic Inventory Management on Logistics Organization’s Performance’, International Journal of Business and Technology Management, 5(3), pp. 288–298.

Suryo, S.H. et al. (2018) ‘Material Strength Analysis on Track Shoe Excavator Using Abrasive Wear Testing Using Pin-on-Disk Method’, Innovative Systems Design and Engineering, 9(6), p. 4.

Zhu, S. et al. (2023) ‘Analysis of regional wear failure of crankshaft pair of heavy duty engine’, Engineering Failure Analysis, 154, p. 107635. Available at: https://doi.org/10.1016/j.engfailanal.2023.107635.