Analysis of the Construction Form of an Electrical Car Chassis Prototype Type Hollow Alumunium 6061 Pipe Profile Using Inventor Software 2019

DOI:

https://doi.org/10.35814/hhx5bh28Keywords:

Prototype, inventor, von mises stress, displacement, safety factor.Abstract

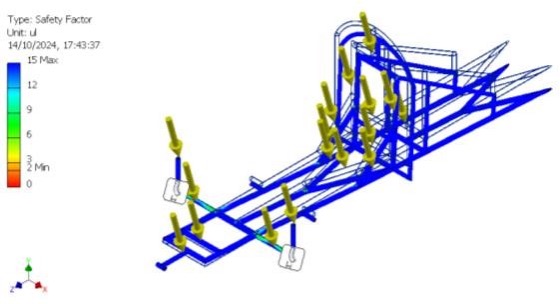

The chassis is a critical structural component in vehicle design, especially in electric vehicle (EV) development aimed at reducing environmental impact. This study analyzes the structural performance of a prototype electric vehicle chassis made from 6061 hollow aluminum using Autodesk Inventor 2019. Three chassis models were designed and tested under a static load of 900 N to compare stress distribution, displacement, and safety factors. All chassis designs had dimensions of 2160 mm × 750 mm × 500 mm with a wall thickness of 2 mm. Simulation results showed that the H-type chassis model performed best, with a von Mises stress of 36.03 MPa, displacement of 4.28 mm, and a safety factor of 7.63. These results indicate that the H-type chassis is structurally safe and suitable for prototype application.

Downloads

References

Abbas, H., Juma, D. and Jahuddin, M.R. (2020) ‘Penerapan Metode Elemen Hingga Untuk Desain Dan Analisis Pembebanan Rangka Chassis Mobil Model Tubular Space Frame’, ILTEK : Jurnal Teknologi, 15(02), pp. 96–102. Available at: https://doi.org/10.47398/iltek.v15i02.32.

Ary, A.K., Prabowo, A.R. and Imaduddin, F. (2020) ‘Structural Assessment of an Energy-Efficient Urban Vehicle Chassis using Finite Element Analysis – A Case Study’, Procedia Structural Integrity, 27, pp. 69–76. Available at: https://doi.org/10.1016/j.prostr.2020.07.010.

Durgam, S. et al. (2021) ‘Experimental and Numerical Studies on Materials for Electric Vehicle Chassis’, in IOP Conference Series: Materials Science and Engineering. 3rd International Conference on trends in Material Science and Inventive Materials (ICTMIM 2021), Coimbatore, India: IOP Publishing Ltd, p. 012073. Available at: https://doi.org/10.1088/1757-899X/1126/1/012073.

Ellianto, M.S.D. and Nurcahyo, Y.E. (2020) ‘Rancang Bangun dan Simulasi Pembebanan Statik pada Sasis Mobil Hemat Energi Kategori Prototype’, Jurnal Engine: Energi, Manufaktur, dan Material, 4(2), pp. 53–58. Available at: https://doi.org/10.30588/jeemm.v4i2.753.

Farghali, M. et al. (2023) ‘Strategies To Save Energy In The Context Of The Energy Crisis: A Review’, Environmental Chemistry Letters, 21(4), pp. 2003–2039. Available at: https://doi.org/10.1007/s10311-023-01591-5.

Hendarmin, D.W., Hanifi, R. and Naubnome, V. (2023) ‘Perancangan Struktur Mobil Listrik “JETZ” dan Analisis Statik Menggunakan Fea (Finite Element Analysis)’, Mutiara: Multidiciplinary Scientifict Journal, 1(10), pp. 526–531. Available at: https://doi.org/10.57185/mutiara.v1i10.74.

Hendrawan, M.A. et al. (2018) ‘Perancanganchassis Mobil Listrik Prototype “Ababil” dan Simulasi Pembebanan Statik dengan Menggunakan Solidworks Premium 2016’, in Proceeding of The 7th University Research Colloquium 2018: Bidang Teknik dan Rekayasa. The 7th University Research Colloquium 2018: Bidang Teknik dan Rekayasa, Surakarta, Indonesia: Universitas Muhammadiyah Surakarta, pp. 96–105. Available at: https://repository.urecol.org/index.php/proceeding/article/view/22 (Accessed: 11 August 2025).

Hirsch, J. (2011) ‘Aluminium in Innovative Light-Weight Car Design’, Materials Transactions, 52(5), pp. 818–824. Available at: https://doi.org/10.2320/matertrans.L-MZ201132.

Kumar, A.H. and Deepanjali, V. (2016) ‘Design & Analysis of Automobile Chassis’, International Journal of Engineering Science and Innovative Technology (IJESIT), 5(1), pp. 187–196.

Lee, D.-C. and Han, C.-S. (2009) ‘CAE (Computer Aided Engineering) Driven Durability Model Verification For The Automotive Structure Development’, Finite Elements in Analysis and Design, 45(5), pp. 324–332. Available at: https://doi.org/10.1016/j.finel.2008.10.004.

Mat, M.H. and Ghani, A.R.Ab. (2012) ‘Design and Analysis of “Eco” Car Chassis’, Procedia Engineering, 41, pp. 1756–1760. Available at: https://doi.org/10.1016/j.proeng.2012.07.379.

Rao, K.S. et al. (2017) ‘Design And Analysis Of Light Weighted Chassis’, International Journal of Mechanical Engineering and Technology (IJMET), 8(5), pp. 96–103.

Tisza, M. and Czinege, I. (2018) ‘Comparative Study Of The Application Of Steels And Aluminium In Lightweight Production Of Automotive Parts’, International Journal of Lightweight Materials and Manufacture, 1(4), pp. 229–238. Available at: https://doi.org/10.1016/j.ijlmm.2018.09.001.

Tsirogiannis, E.C., Stavroulakis, G.E. and Makridis, S.S. (2019) ‘Electric Car Chassis for Shell Eco Marathon Competition: Design, Modelling and Finite Element Analysis’, World Electric Vehicle Journal, 10(1), p. 8. Available at: https://doi.org/10.3390/wevj10010008.

Wibowo, M.Y. et al. (2022) ‘Perancangan Chassis Prototype Mobil Warak dan Simulasi Statik dengan Metode Finite Element Analysis’, Jurnal Mekanik Terapan, 3(3), pp. 86–92. Available at: https://doi.org/10.32722/jmt.v3i3.5138.

Zamzam, O. et al. (2025) ‘Structural Performance Evaluation Of Electric Vehicle Chassis Under Static And Dynamic Loads’, Scientific Reports, 15(1), p. 5168. Available at: https://doi.org/10.1038/s41598-025-86924-w.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa & Inovasi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.