Influence of Several True-Solvent, Co-Solvent and Non-Solvent on Thinner in Coating Adhesion And Thickness Automotive Paint

DOI:

https://doi.org/10.35814/asiimetrik.v7i2.8498Keywords:

thinner, coating thickness, paint automotive, solvent, surface roughnesAbstract

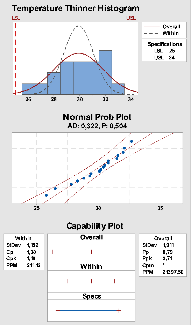

Choosing better organic solvents and providing appropriate mixing ratios for thinner in the automotive paint industry. The research objects were true solvents, ethyl acetate, butyl acetate, and acetone; alcohol cosolvents are isopropyl alcohol, isobutyl alcohol; and non-solvents are n-heptane, propylene glycol, and mineral spirits. Adhesion and coating thickness by spray paint and turbidity of thinner were performed. The thinner dissolving rate was evaluated by immersing coated galvalume plates (50 mm × 50 mm × 0.4 mm) into thinner and recording the time required to dissolve the paint. Thinner testing was conducted using a spray method at 17 cm distance and 90° angle, with coating thickness measured by coating thickness gauge and adhesion evaluated using the ASTM D3359 tape test. The best Performance was observed in the 5:3:3 composition (EA:IPA:MS), which achieved a 5B adhesion rating and a coating thickness of 60.7 µm. This ratio also had the lowest turbidity value (0.11 ± 0.02 NTU). Based on the capability plot analysis, this composition demonstrated high process capability (Cp = 3.06; Cpk = 2.52), confirming its suitability as the optimal formulation for automotive thinner applications.

Downloads

References

Agin, K. et al. (2016) ‘Characteristic Manifestations Of Acute Paint Thinner-Intoxicated Children’, Environmental Toxicology and Pharmacology, 45, pp. 15–19. Available at: https://doi.org/10.1016/j.etap.2016.05.001.

Chen, S. et al. (2019) ‘Effect Of Initial Temperature And Initial Pressure On Vapor Explosion Characteristics Of Nitro-Thinner’, Journal of Loss Prevention in the Process Industries, 61, pp. 298–304. Available at: https://doi.org/10.1016/j.jlp.2019.05.020.

Gan, W. et al. (2017) ‘Transparent Magnetic Wood Composites Based On Immobilizing Fe3O4 Nanoparticles Into A Delignified Wood Template’, Journal of Materials Science, 52(6), pp. 3321–3329. Available at: https://doi.org/10.1007/s10853-016-0619-8.

Gupta, R. et al. (2023) ‘A Critical Review On Recent Progress, Open Challenges, And Applications Of Corrosion-Resistant Superhydrophobic Coating’, Materials Today Communications, 34, p. 105201. Available at: https://doi.org/10.1016/j.mtcomm.2022.105201.

Liang, L. et al. (2022) ‘Effects Of Several Cosolvents And Non-Solvents On Ester True Solvents In Nitrocellulose Lacquer Thinner’, Progress in Organic Coatings, 172, p. 107063. Available at: https://doi.org/10.1016/j.porgcoat.2022.107063.

Luo, Q. et al. (2018) ‘The Thermal Properties of Nitrocellulose: From Thermal Decomposition to Thermal Explosion’, Combustion Science and Technology, 190(4), pp. 579–590. Available at: https://doi.org/10.1080/00102202.2017.1396586.

Mulyanto, T., Supriyono and Arta, S.P. (2020) ‘Pengaruh Perlakuan Awal Terhadap Daya Rekat dan Kekuatan Lapisan pada Proses Pengecatan Serbuk’, Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa & Inovasi, 2(1), pp. 25–32. Available at: https://doi.org/10.35814/asiimetrik.v2i1.1186.

Osemeahon, S.A. et al. (2024) ‘Characterization And Application Of Composite Resin Of Natural Rubber Latex And Polystyrene Waste As A Binder For Water-Resistant Emulsion Paint Formulation’, Progress in Rubber, Plastics and Recycling Technology, p. 14777606241281624. Available at: https://doi.org/10.1177/14777606241281624.

Rio, K. et al. (2020) ‘Studi: Potensi Solvent N-Butanol sebagai Substituen Toluena dalam Larutan Thinner’, in Prosiding Seminar Nasional Kimia (SNK) 2020. Seminar Nasional Kimia (SNK) 2020, Surabaya, Indonesia: Universitas Negeri Surabaya, pp. 249–257.

Schweitzer, P.A. (2005) Paint and Coatings: Applications and Corrosion Resistance. New York: CRC Press. [Print].

Sopiyan, Iqbal, M. and Susetyo, F.B. (2022a) ‘Efek Variasi Campuran Solvent-Varnish dan Suhu Pengeringan terhadap Karakteristik Pelapis’, Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa & Inovasi, 4(1), pp. 35–42. Available at: https://doi.org/10.35814/asiimetrik.v4i1.2450.

Sopiyan, Iqbal, M. and Susetyo, F.B. (2022b) ‘Pengaruh Variasi Temperatur Pengeringan Terhadap Daya Kilap Cat Pada Komponen Kendaraan Bermotor: Effect of Variation in Drying Temperature on Paint Glossy on Motor Vehicle Components’, METALIK : Jurnal Manufaktur, Energi, Material Teknik, 1(1), pp. 16–21. Available at: https://doi.org/10.22236/metalik.v1i1.8462.

Xi, J. et al. (2019) ‘Acute Toxicity Of Triflumizole To Freshwater Green Algae Chlorella Vulgaris’, Pesticide Biochemistry and Physiology, 158, pp. 135–142. Available at: https://doi.org/10.1016/j.pestbp.2019.05.002.

Xu, W. et al. (2020) ‘Comparison Of Six Ester Components In Nitrocellulose Lacquer Thinner From The Aspects Of Dissolution Rates, Explosion Characteristics And Environmental Influence’, Progress in Organic Coatings, 139, p. 105426. Available at: https://doi.org/10.1016/j.porgcoat.2019.105426.

Zhang, S. et al. (2021) ‘Enhancement Of Magnetic Film With Light Penetration By Immobilization Of Fe3O4 Nanoparticles In A Spherical Bamboo Nanocellulose Network’, Cellulose, 28(7), pp. 4179–4189. Available at: https://doi.org/10.1007/s10570-021-03802-0.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa & Inovasi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.