Design of a Seaweed Draining and Drying Machine Using Hybrid Energy

DOI:

https://doi.org/10.35814/asiimetrik.v7i2.8636Keywords:

design, seaweed, draining, drying, hybrid energyAbstract

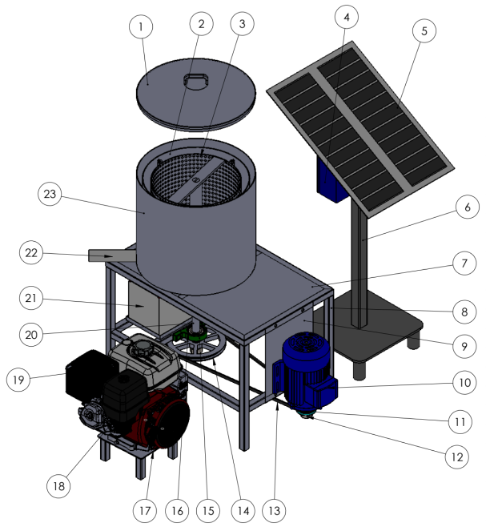

Seaweed is a plant that is adaptable and is used in a variety of industries, such as food, cosmetics, and medication. However, the current seaweed processing technique, which entails sun drying, is still highly traditional and requires a significant amount of time. To speed up draining and drying seaweed, we developed a hybrid energy-powered seaweed draining and drying. The tool capacity of this design is 50 kg, and it applies the Pahl and Beitz method. The selected design is variant 3 with the highest weight value of 7.74. The design outcomes produce the following tool specifications the drive is equipped with a diesel motor with a power of 3.5 Hp, 2.6 kW, and 3600 rpm, as well as three solar panels of the MCS1100 model, each with a capacity of 100 Wp. The container dimensions of 382 mm diameter and 500 mm height. The seaweed is to be dried at a rate of 29,3 kg/m2 per hour. The galvanized steel frame yielded a maximum working stress value of 126.223 N/mm2, which is lower than the material's yield strength value of 203.943 N/mm2. On the shaft made of S45C8 steel, the maximum working stress value after applying the load is 66.83 N/mm2, which is also less than the material's yield strength value of 350 N/mm2. This indicates that the stand and shaft design is safe, as the simulation process's maximum stress value does not surpass the material's yield strength value.

Downloads

References

Alfith et al. (2023) ‘Sistem Monitoring Suhu Dan Intensitas Cahaya Pada Solar Panel 3 WP Berbasis IoT (Internet of Things)’, Jurnal Teknologi dan Vokasi, 1(2), pp. 31–38. Available at: https://doi.org/10.21063/jtv.2023.1.2.4.

Bappedalitbang (2024) Potensi Kabupaten Nunukan, SIMPotensi Ekonomi Povinisi Kalimantan Utara. Available at: https://potensiekonomi.kaltaraprov.go.id/potensi-kabupaten-nunukan (Accessed: 6 November 2024).

Basyuni, M. et al. (2024) ‘Current biodiversity status, distribution, and prospects of seaweed in Indonesia: A systematic review’, Heliyon, 10(10), p. e31073. Available at: https://doi.org/10.1016/j.heliyon.2024.e31073.

Brigljević, B., Liu, J. and Lim, H. (2019) ‘Green Energy from Brown Seaweed: Sustainable Polygeneration Industrial Process Via Fast Pyrolysis of S. Japonica Combined with the Brayton Cycle’, Energy Conversion and Management, 195, pp. 1244–1254. Available at: https://doi.org/10.1016/j.enconman.2019.05.103.

FAO (2024) Aquaculture production 2022, The State Of World Fisheries And Aquaculture 2022. Available at: https://doi.org/10.4060/cc0461en. (Accessed: 10 November 2024).

Golberg, A. et al. (2021) ‘Hybrid Solar-Seaweed Biorefinery For Co-Production Of Biochemicals, Biofuels, Electricity, And Water: Thermodynamics, Life Cycle Assessment, And Cost-Benefit Analysis’, Energy Conversion and Management, 246, p. 114679. Available at: https://doi.org/10.1016/j.enconman.2021.114679.

Khurmi, R.S. and Gupta, J.K. (2005) A Textbook of Machine Design. S. Chand Publishing. [Print].

Lamidi, Rasaq.O. et al. (2019) ‘Recent Advances In Sustainable Drying of Agricultural Produce: A Review’, Applied Energy, 233–234, pp. 367–385. Available at: https://doi.org/10.1016/j.apenergy.2018.10.044

Nagahawatta, D.P. et al. (2021) ‘Drying Seaweeds Using Hybrid Hot Water Goodle Dryer (HHGD): Comparison with Freeze-Dryer in Chemical Composition and Antioxidant Activity’, Fisheries and Aquatic Sciences, 24(1), pp. 19–31. Available at: https://doi.org/10.47853/FAS.2021.e3.

Pahl, G. and Beitz, W. (2013) Engineering Design: A Systematic Approach. Springer Science & Business Media. [Print].

Pangan, R., Ampo, M.V. and Barredo, Y. (2021) ‘Design, Development and Evaluation of Seaweed Drying Technology for Village Level Operation’, Philippine Journal of Agricultural and Biosystems Engineering, 17(1), pp. 13–25. Available at: https://doi.org/10.48196/017.01.2021.02.

Putra, A.F.S. et al. (2024) ‘Perancangan Sistem Alat Pengering Rumput Laut Otomatis dengan Pengintegrasian Panel Surya’, Industrika : Jurnal Ilmiah Teknik Industri, 8(3), pp. 479–487. Available at: https://doi.org/10.37090/indstrk.v8i3.1365.

Rahman, M.R. and Abdullah, S. (2020) Pada 2020 KKP targetkan produksi 10,99 juta ton rumput laut, ANTARA News Jambi. Available at: https://jambi.antaranews.com/berita/369775/pada-2020-kkp-targetkan-produksi-1099-juta-ton-rumput-laut (Accessed: 6 November 2024).

SAAJ (2024) 45C8 Properties, Saaj Steel Corporation. Available at: https://saajsteel.com/carbon-steel-round-bar-manufacturers-and-suppliers-in-chennai/45c8-carbon-steel-bar-manufacturers-suppliers-in-chennai/ (Accessed: 13 November 2024).

Saini, R.K. et al. (2023) ‘Technological Development in Solar Dryers from 2016 to 2021-A Review’, Renewable and Sustainable Energy Reviews, 188, p. 113855. Available at: https://doi.org/10.1016/j.rser.2023.113855.

Salim, Z. and Ernawati (eds) (2015) Info Komoditi Rumput Laut. Jakarta: Badan Pengkajian dan Pengembangan Kebijakan Perdagangan : Al Mawardi Prima. [Print].

Setiawan, R. (2023) ‘Rancang Bangun Alat Pengering Rumput Laut Bertenaga Surya Menggunakan Metode Fuzzy’, Journal ICTEE, 4(2), pp. 37–46. Available at: https://doi.org/10.33365/jictee.v4i2.2509.

Setiawan, W., Jaya, I. and Hestirianoto, T. (2011) ‘Rancang Bangun Mesin Pencuci Rumput Laut Berbasis Teknologi Hybrid’, Jurnal Teknologi Perikanan dan Kelautan, 2(1), pp. 47–56. Available at: https://doi.org/10.24319/jtpk.2.47-56.

SKF (2024) SKF Pullys, SKF Group homepage | SKF. Available at: http://www.bearing.net.au/wp-content/uploads/2014/07/SKF-Pulley-Catalogue.pdf (Accessed: 10 November 2024).

Suwandi, A. et al. (2021) ‘Rancang Bangun Bed Storage untuk Thermal Energy Storage Berbasis Parafin dan Serbuk Besi’, JTERA (Jurnal Teknologi Rekayasa), 6(1), pp. 163–174. Available at: https://doi.org/10.31544/jtera.v6.i1.2021.163-174.

Suwandi, A. et al. (2023) ‘The Development of Exhaust Fan Housing with Ceiling Mounting for High Rise Buildings by Using DFMA’, Journal of Applied Engineering and Technological Science (JAETS), 4(2), pp. 895–907. Available at: https://doi.org/10.37385/jaets.v4i2.1675.

Yong, W.T.L. et al. (2022) ‘Seaweed: A Potential Climate Change Solution’, Renewable and Sustainable Energy Reviews, 159, p. 112222. Available at: https://doi.org/10.1016/j.rser.2022.112222.

Zhang, L. et al. (2022) ‘Global Seaweed Farming and Processing in The Past 20 Years’, Food Production, Processing and Nutrition, 4(1), p. 23. Available at: https://doi.org/10.1186/s43014-022-00103-2.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa & Inovasi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.