Chemical Grinding Aids as Chemical Agents to Enhance the Efficiency of Clinker Grinding in Cement Plants

DOI:

https://doi.org/10.35814/asiimetrik.v7i2.8763Keywords:

chemical grinding aids, cement production, cementAbstract

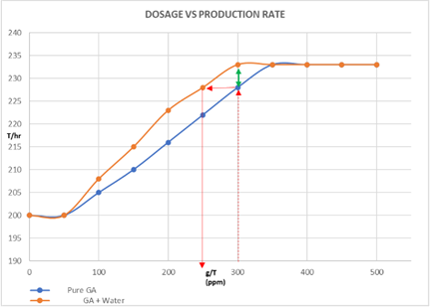

Chemical Grinding Aids, hereinafter referred to as Grinding Aids, are chemical additives used to optimize the grinding process of clinker and other supplementary materials into cement powder. In practice, these Grinding Aids enhance the efficiency of the grinding process, thereby increasing the capacity of the grinding equipment. As a result of this increased capacity, the electrical energy consumption per ton of cement produced is reduced, leading to a proportional decrease in production costs per ton. In addition to improving productivity, the use of Grinding Aids also contributes to better cement quality. Experimental data presented in this article show that the application of Grinding Aids has a positive impact, increasing production by up to 17% with an optimal dose of 350 ppm when using concentrated Grinding Aids without dilution. Meanwhile, the optimal dose for a Grinding Aid solution diluted in water at a ratio of 1:4 (grinding aids:water) is 300 ppm. This improvement in productivity also leads to a 5% reduction in electricity consumption during the cement grinding process.

Downloads

References

Alfaredo, P., Nugraha, D. and Uddin, S. (2022) ‘Sistem Pengendalian Feeding Dengan Menggunakan Weight Fedeer di PT. Semen Baturaja (Persero) Tbk’, Jurnal Vokasi JUVI, 1(1), pp. 1–8.

Assaad, J.J., Asseily, S.E. and Harb, J. (2009) ‘Effect Of Specific Energy Consumption On Fineness Of Portland Cement Incorporating Amine Or Glycol-Based Grinding Aids’, Materials and Structures, 42(8), pp. 1077–1087. Available at: https://doi.org/10.1617/s11527-008-9444-0.

Chipakwe, V. et al. (2020) ‘A Critical Review On The Mechanisms Of Chemical Additives Used In Grinding And Their Effects On The Downstream Processes’, Journal of Materials Research and Technology, 9(4), pp. 8148–8162. Available at: https://doi.org/10.1016/j.jmrt.2020.05.080.

Fatahi, R. et al. (2022) ‘Modeling Of Energy Consumption Factors For An Industrial Cement Vertical Roller Mill By SHAP-XGboost: A “Conscious Lab” Approach’, Scientific Reports, 12(1), p. 7543. Available at: https://doi.org/10.1038/s41598-022-11429-9.

Febriani, S. (2022) ‘Analisis Deskriptif Standar Deviasi’, Jurnal Pendidikan Tambusai, 6(1), pp. 910–913. Available at: https://doi.org/10.31004/jptam.v6i1.8194.

Gharehgheshlagh, H.H., Chehreghani, S. and Seyyedi, B. (2023) ‘Effects Of Various Grinding Aids Dosage On Comminution Efficiency And Cement Characteristics’, Rudarsko-geološko-naftni zbornik, 38(1), pp. 69–82. Available at: https://doi.org/10.17794/rgn.2023.1.7.

IEA (2021) Driving Energy Efficiency in Heavy Industries: Global energy efficiency benchmarking in cement, iron & steel. The International Energy Agency (IEA). Available at: https://www.iea.org/articles/driving-energy-efficiency-in-heavy-industries (Accessed: 10 April 2025).

Jiang, Y. et al. (2023) ‘Study on Preparation and Performance of Liquid Grinding Aid’, in Proceedings of the 2023 5th International Conference on Structural Seismic and Civil Engineering Research (ICSSCER 2023). 5th International Conference on Structural Seismic and Civil Engineering Research (ICSSCER 2023), India: Atlantis Press, pp. 128–135. Available at: https://doi.org/10.2991/978-94-6463-312-2_14.

Kalkan, Ö. (2023) Effect Of Grinding Chemicals And Aids On The Grinding Efficiency And The Performance Of Portland Cement. Thesis. Middle East Technical University. Available at: https://doi.org/10.13140/RG.2.2.24071.10407.

Lavagna, L. and Nisticò, R. (2023) ‘An Insight into the Chemistry of Cement—A Review’, Applied Sciences, 13(1), p. 203. Available at: https://doi.org/10.3390/app13010203.

Mapei (2005) ‘Enhanced Performance’, ICR, pp. 105–110.

Max, S.V. et al. (2023) ‘Study and Modeling of the Grinding Kinetics of Reactive Rocks in a Cement Laboratory’, Journal of Minerals and Materials Characterization and Engineering, 11(06), pp. 224–248. Available at: https://doi.org/10.4236/jmmce.2023.116017.

Njiru, E.N. et al. (2023) ‘Review of the Effect of Grinding Aids and Admixtures on the Performance of Cements’, Advances in Civil Engineering, 2023(1), p. 6697842. Available at: https://doi.org/10.1155/2023/6697842.

Popov, A. and Chernev, G. (2024) ‘Effect of Grinding Aids on Cement Properties and Grinding Process’, Journal of Chemical Technology and Metallurgy, 59(6), pp. 1327–1330. Available at: https://doi.org/10.59957/jctm.v59.i6.2024.6.

Prziwara, P. and Kwade, A. (2021) ‘Grinding Aid Additives For Dry Fine Grinding Processes – Part II: Continuous And Industrial Grinding’, Powder Technology, 394, pp. 207–213. Available at: https://doi.org/10.1016/j.powtec.2021.08.039.

Sunarsih, T. et al. (2024) ‘Pengaruh Penambahan Dosis Cement Grinding Aid (CGA) Terhadap Setting Time dan Kuat Tekan Mortar Pada Semen PCC di PT Semen Baturaja Tbk’, PARADIGM : Journal Of Multidisciplinary Research and Innovation, 2(02), pp. 124–141. Available at: https://doi.org/10.62668/paradigm.v2i02.1192.

Urbaniak, D. et al. (2021) ‘Research on the Grinding Energy Density in a Jet Mill’, Materials, 14(8), p. 2008. Available at: https://doi.org/10.3390/ma14082008.

Yang, J. et al. (2022) ‘Effect of Polycarboxylic Grinding Aid on Cement Chemistry and Properties’, Polymers, 14(18), p. 3905. Available at: https://doi.org/10.3390/polym14183905.

Zhao, H. (2021) ‘Analysis on Influencing Factors of Grinding Aid Effect of Cement Grinding Aids’, in Journal of Physics: Conference Series. 2020 International Conference on Applied Mechanics and Mechanical Engineering (ICAMME 2020), Hulun Buir, China: IOP Publishing Ltd, p. 012037. Available at: https://doi.org/10.1088/1742-6596/1798/1/012037.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa & Inovasi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.