Different Quenching Media Effect on Microstructure, Hardness,and Corrosion of Medium Carbon Steel

DOI:

https://doi.org/10.35814/asiimetrik.v7i2.8793Keywords:

distilled water, engine oil, saline water, electric furnaceAbstract

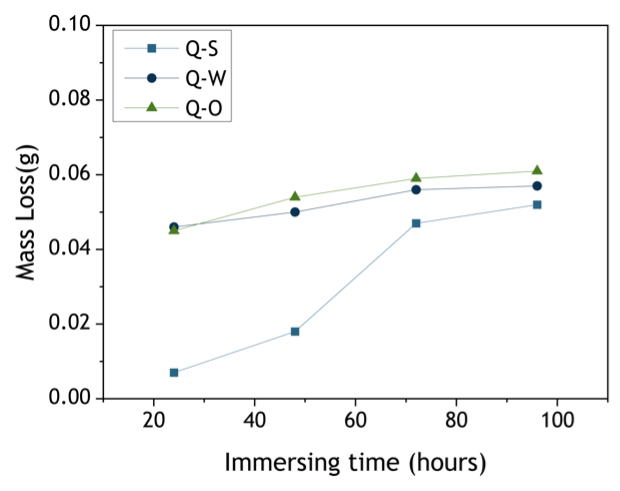

Medium carbon steel is widely used due to could conduct heat treatment to modify the microstructure and mechanical properties. Quenching is one method to modify the microstructure and mechanical properties. In the present study conducted heating samples at 850°C using an electric furnace, then held them for 60 minutes and quenched in various media (saline water, oil, and distilled water). Afterward, the quenched sample was investigatedmicrostructure, hardness, and corrosion using an optical microscope, Vickers hardness tester, and weight loss method. 5% NaCl quenching media could result in samples more uniform and martensite due to the high cooling rate.More uniforms and martensite have the beneficial highest hardness and lowest corrosion rate for around 762.4 HV and 76.04 mpy.

Downloads

References

Aruan, R., Pratikno, H. and Hadiwidodo, Y. (2023) ‘Analisis Pengaruh Suhu Material Pada Pengaplikasian Coating Epoxy Terhadap Kekuatan Adhesi Baja A36’, Jurnal Teknik ITS, 12(1), pp. F34–F40. Available at: https://doi.org/10.12962/j23373539.v12i1.110657.

Arulvel, S. et al. (2023) ‘Hydrophobic Electroless Nickel Phosphorus-Graphene Carbon Nitride Coating On AISI 4140 Steel With Enhanced Hardness And Scratch Resistance’, Surface and Coatings Technology, 473, p. 130023. Available at: https://doi.org/10.1016/j.surfcoat.2023.130023.

Baihaqi, R.A., Pratikno, H. and Hadiwidodo, Y.S. (2019) ‘Analisis Sour Corrosion pada Baja ASTM A36 Akibat Pengaruh Asam Sulfat dengan Variasi Temperatur dan Waktu Perendaman di Lingkungan Laut’, Jurnal Teknik ITS, 8(2), pp. G237–G242. Available at: https://doi.org/10.12962/j23373539.v8i2.45896.

Basori, I. et al. (2024) ‘The Effect of Quenching Process on The Microstructure and Hardness of AISI 4140 Steel’, in Journal of Physics: Conference Series. 13th International Physics Seminar 2024, Jakarta, Indonesia: IOP Publishing Ltd, p. 012020. Available at: https://doi.org/10.1088/1742-6596/2866/1/012020.

Brito, P. et al. (2019) ‘Experimental Investigation Of Cooling Behavior And Residual Stresses For Quenching With Vegetable Oils At Different Bath Temperatures’, Journal of Cleaner Production, 216, pp. 230–238. Available at: https://doi.org/10.1016/j.jclepro.2019.01.194.

Buku, A. et al. (2020) ‘Analysis of Wear Test and Micro Structure of Low Carbon Steel through nietryding Process’, Chimica Techno Acta, 5, pp. 93–99. Available at: https://doi.org/10.31960/tea.v5i.

Chen, C. et al. (2019) ‘Nano-BaTiO3 Phase Transition Behavior in Coated BaTiO3-based Dielectric Ceramics’, Ceramics International, 45(6), pp. 7166–7172. Available at: https://doi.org/10.1016/j.ceramint.2018.12.223.

Chen, Z., Nash, P. and Zhang, Y. (2019) ‘Correlation of Cooling Rate, Microstructure and Hardness of S34MnV Steel’, Metallurgical and Materials Transactions B, 50(4), pp. 1718–1728. Available at: https://doi.org/10.1007/s11663-019-01621-0.

Djuanda et al. (2021) ‘Analisis Pengaruh Media Pendingin terhadap Struktur Mikro Sambungan Pengelasan Baja AISI 1045 pada Proses Las MIG’, TEKNOLOGI: Jurnal Teknik Mesin, 22(1 APR), pp. 43–54.

Haryadi, G.D., Utomo, A.F. and Ekaputra, I.M.W. (2021) ‘Pengaruh Variasi Temperatur Quenching Dan Media Pendingin Terhadap Tingkat Kekerasan Baja AISI 1045’, Jurnal Rekayasa Mesin, 16(2), pp. 255–264. Available at: https://doi.org/10.32497/jrm.v16i2.2633.

Klemm-Toole, J. et al. (2019) ‘A Quantitative Evaluation Of Microalloy Precipitation Strengthening In Martensite And Bainite’, Materials Science and Engineering: A, 763, p. 138145. Available at: https://doi.org/10.1016/j.msea.2019.138145.

Lostari, A. (2022) ‘Pengaruh Media Pendinginan Pada Proses Heat Treatment Baja SUP-9’, ROTASI, 24(3), pp. 29–35. Available at: https://doi.org/10.14710/rotasi.24.3.29-35.

Maitimu, C.G. et al. (2024) ‘Analisa Laju Korosi Pipa Sch 40 Seamless Dengan Variasi Media Pengkorosian Air Payau Dan Air Laut’, Journal Mechanical Engineering, 2(2), pp. 183–192. Available at: https://doi.org/10.31959/jme.v2i2.2920.

Nikhil et al. (2021) ‘Investigation On The Effects Of Cooling Rate On Surface Texture, Corrosion Behaviour And Hardness Of Pure Copper’, Materials Today: Proceedings, 47, pp. 6693–6695. Available at: https://doi.org/10.1016/j.matpr.2021.05.115.

Prabowo, A.A. and Sunyoto, S. (2020) ‘Pengaruh Media Pendingin Pada Proses Quenching Terhadap Kekerasan, Struktur Mikro, Dan Kekuatan Bending Baja AISI 1010’, JMEL : Journal of Mechanical Engineering Learning, 9(1). Available at: https://journal.unnes.ac.id/sju/jmel/article/view/40310.

Prayitno, D. and Indayanto, P.P. (2021) ‘Pengaruh Hardening Terhadap Korosi Pada Baja S45C’, Metrik Serial Teknologi dan Sains, 2(2), pp. 70–75.

Rachman, M.R.A. and Sakti, A.M. (2020) ‘Analisa Perbedaan Kekerasan Dan Kekuatan Tarik Baja S45C Dengan Perlakuan Quenching dan Tempering Pada Media Udara, Air, Dan Oli Untuk Aplikasi Poros Motor Roda Tiga’, Jurnal Teknik Mesin, 8(2), pp. 89–94.

Ramandika, A. et al. (2022) ‘Pengaruh Lapisan Coating Zinc Cromate Terhadap Korosi Baja Ss400 Plat Kapal Menggunakan Alat Uji Salt Spray Test Type Gt-7004L’, Nozzle : Journal Mechanical Engineering, 11(2), pp. 44–48. Available at: https://doi.org/10.30591/nozzle.v11i2.5862.

Ridho, A.F. and Rokhim, I.N. (2023) ‘Analisis Teknis Dan Ekonomis Korosi Perbandingan ASTM A36 Dan Aluminium 5083 Untuk Pelat Kapal’, JUSTI (Jurnal Sistem dan Teknik Industri), 4(3), pp. 303–311. Available at: https://doi.org/10.30587/justicb.v4i3.7553.

Sopiyan et al. (2024) ‘Enhancement In The Hardness And Corrosion Resistance Of Mild Steel Surfaces By Nickel-Chromium Addition And Rapid Cooling After Welding’, Journal of Applied Science and Engineering, 27(6), pp. 2725–2736. Available at: https://doi.org/10.6180/jase.202406_27(6).0012.

Sopiyan, S., Basori, B. and Susetyo, F.B. (2020) ‘The Effect Of Water Temperature As Quenching Media On The Characteristics Of HV 350 Weld Deposits’, SINTEK JURNAL: Jurnal Ilmiah Teknik Mesin, 14(2), pp. 118–122. Available at: https://doi.org/10.24853/sintek.14.2.118-122.

Sopiyan, S., Syamsuir, S. and Nofendri, Y. (2019) ‘Evaluasi Hasil Hardfacing Elektroda HV 350 Pasca Quenching Media Air, Coolant dan Oli’, JURNAL KAJIAN TEKNIK MESIN, 4(2), pp. 104–107. Available at: https://doi.org/10.52447/jktm.v4i2.1778.

Syaifullah, M., Subhan, M. and Juanda, J. (2021) ‘Pengaruh Air Garam Sebagai Media Pendingin Terhadap Nilai Kekerasan Pada Proses Pengerasan Baja ST 60’, Jurnal Syntax Admiration, 2(8), pp. 1555–1569. Available at: https://doi.org/10.46799/jsa.v2i8.292.

Syaripuddin, S. et al. (2023) ‘Synthesis of Hard Layer by Titanium Addition During Welding Process and Quenched Directly’, International Journal of Engineering, 36(3), pp. 532–539. Available at: https://doi.org/10.5829/ije.2023.36.03c.13.

Wijaya, A. and Rasyid, A.H.A. (2023) ‘Analisa Kekerasan Dan Ketahanan Aus Baja AISI 1045 Akibat Heat Treatment Dengan Variasi Temperatur dan Media Quenching Air Garam Untuk Aplikasi Sprocket Gear’, Jurnal Teknik Mesin, 11(02), pp. 75–80.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Jurnal Asiimetrik: Jurnal Ilmiah Rekayasa & Inovasi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.